01

Liquid Oxygen and Liquid Nitrogen ASU Plant

Product Description

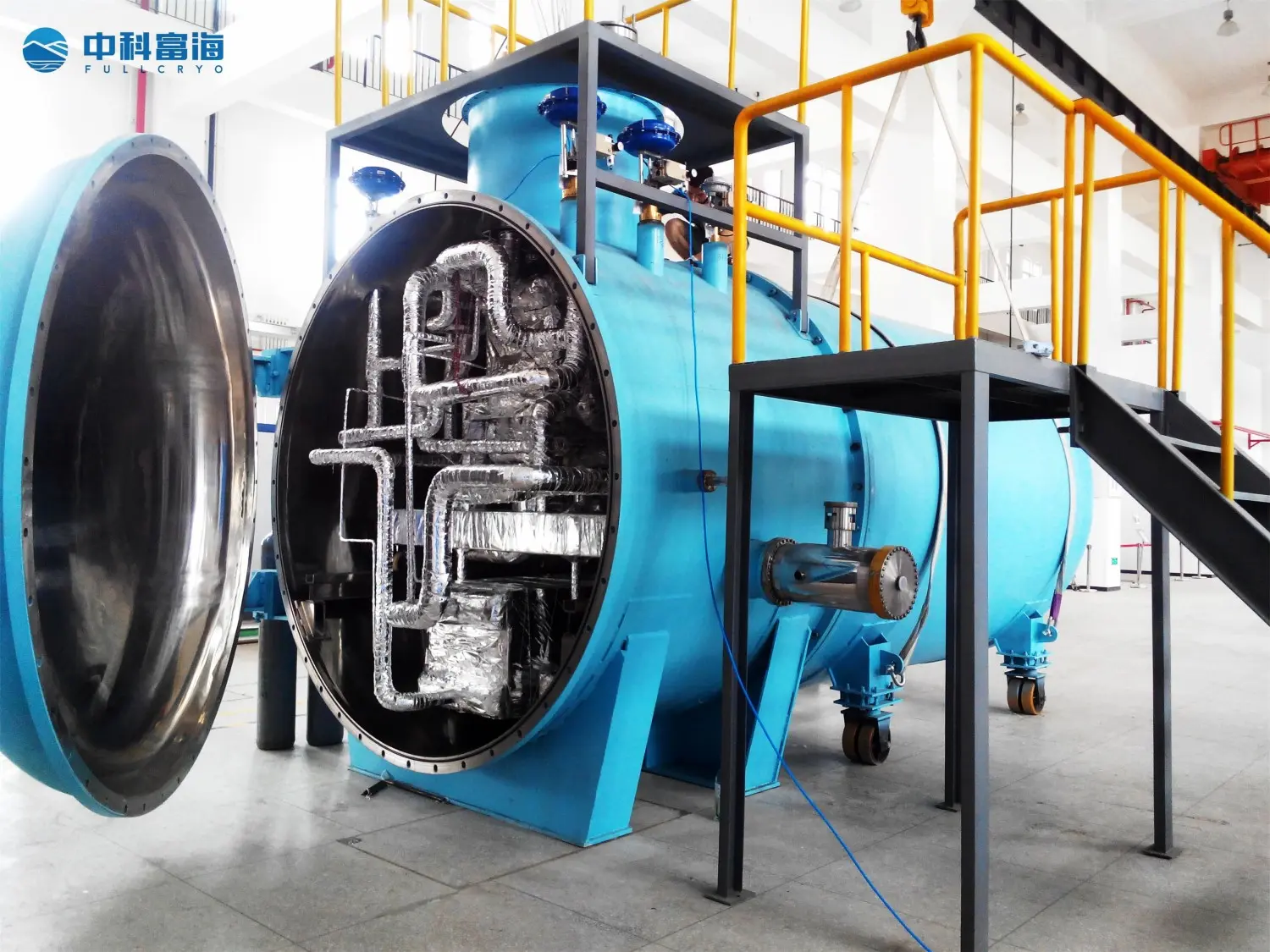

The basic principle of air separation is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen-enriched liquid air. The oxygen-enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen. The upper tower is divided into two sections: with the liquid-air inlet as the boundary, the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove the nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

The function of liquid oxygen and liquid nitrogen is to provide a convenient and efficient way to store and transport these gases for a variety of industrial, medical and scientific applications.

Liquid oxygen is used in respiratory support in medical facilities, in industrial processes such as metal cutting and welding, and in the production of chemicals and fuels. It is also used in the aerospace industry for rocket propulsion and in the medical field for cryotherapy and cryopreservation.

Liquid nitrogen, on the other hand, has a wide range of applications, including as a coolant for preserving biological samples, in the food industry for freezing and packaging, in the semiconductor industry for cooling during manufacturing processes, and in the medical field for use in cryosurgery and dermatology.

The liquid forms of these gases are easier to store and transport than their gaseous counterparts, and also enable precise and controlled delivery of the gas to the point of use. This makes liquid oxygen and liquid nitrogen vital to many critical applications across industries.

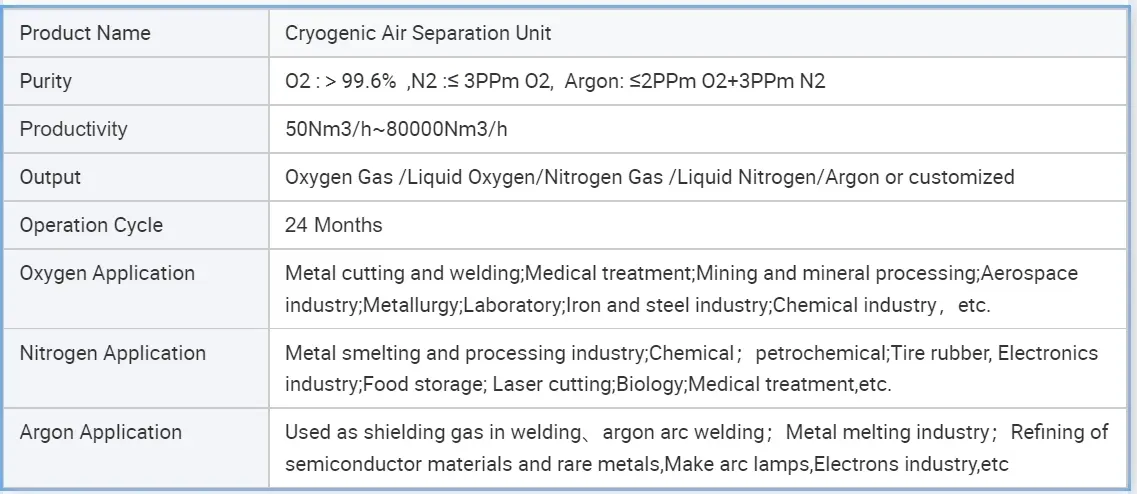

parameter

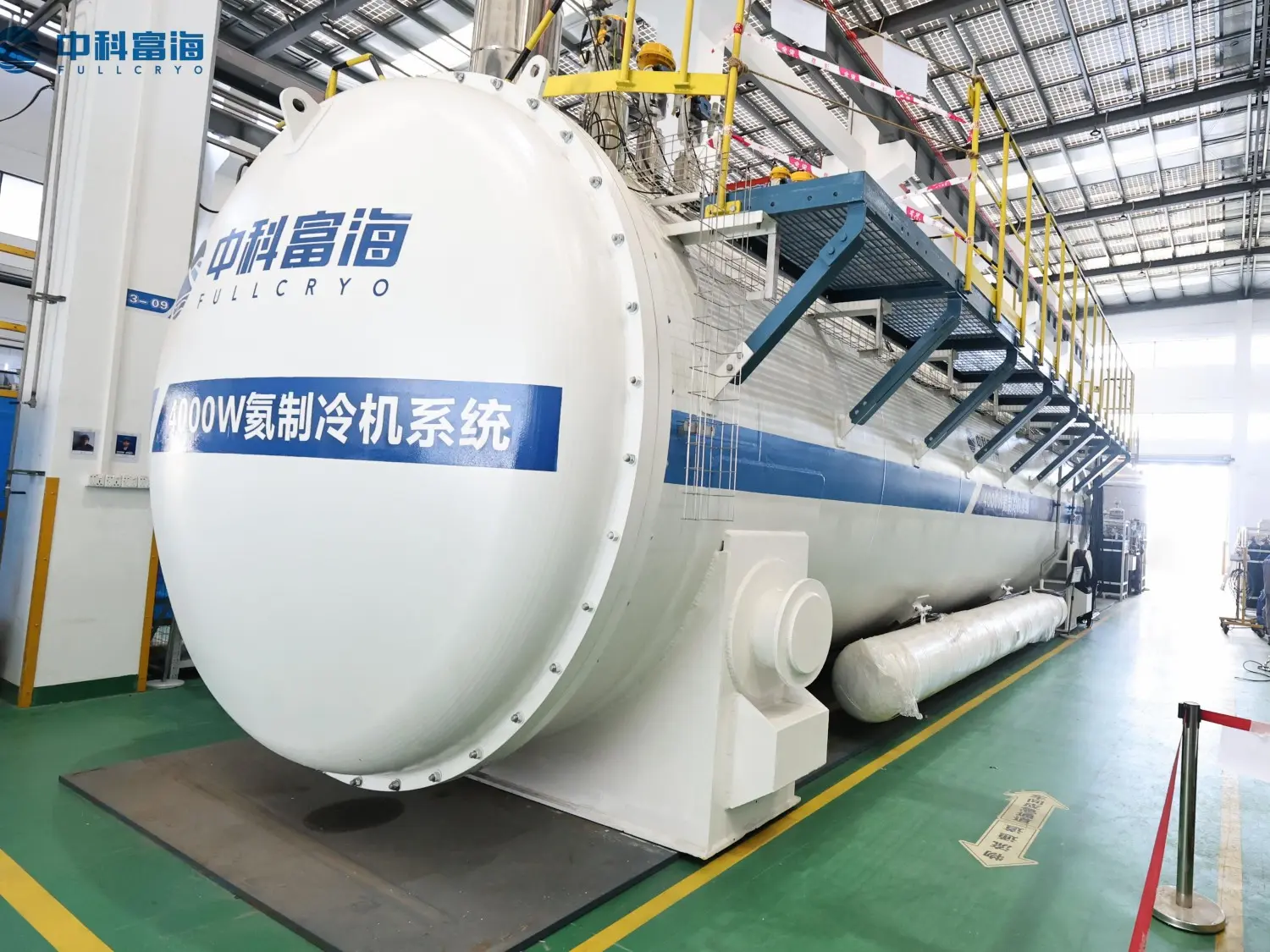

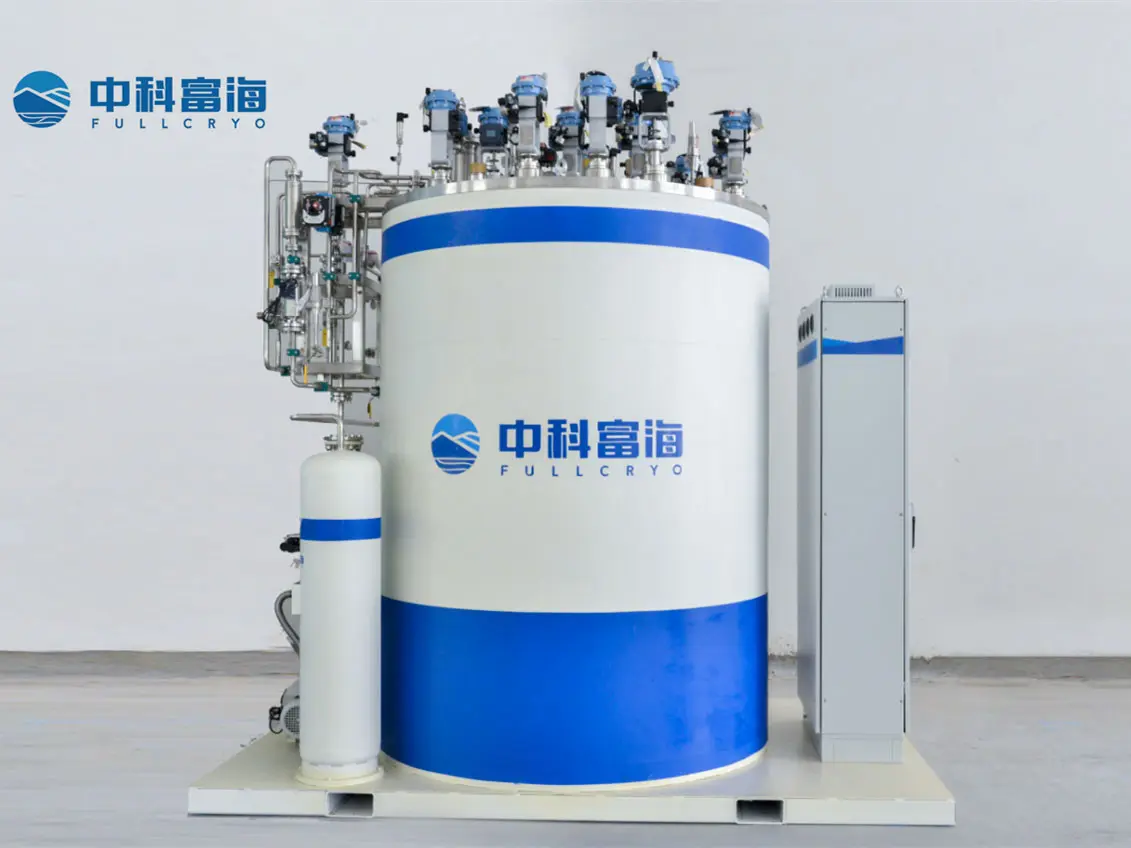

Factory Pictures