01

Oxygen Production Line with Cylinders Filling System

Product Description

An Oxygen Production Line with a Cylinders Filling System is designed to produce high-purity oxygen gas and fill it into high-pressure cylinders for distribution and use in various applications, such as medical, industrial, and commercial purposes.

Operational Steps:

1. Preparation:

Ensure all equipment, including compressors, PSA units, and filling manifolds, are in good working condition.

Inspect cylinders for any damage or contamination before filling.

2. Start-Up:

Begin the air intake process, followed by compression, cooling, and dehydration.

Initiate the air separation process through PSA or cryogenic distillation.

3. Production:

Monitor the oxygen production process, ensuring the desired purity level is consistently achieved.

Continuously compress and purify oxygen for filling.

4. Filling Cylinders:

Connect empty cylinders to the filling manifold.

Gradually open the control valves to fill the cylinders, monitoring the pressure gauges to ensure proper filling.

Close the valves once the desired pressure is reached.

5. Post-Filling:

Perform leak tests on filled cylinders to ensure there are no leaks.

Label and document filled cylinders with necessary information, including pressure, purity, and filling date.

6. Maintenance:

Regularly maintain and service all equipment to ensure efficient and safe operation.

Conduct routine checks and calibration of pressure gauges and safety devices.

Applications:

1. Medical Use:

Oxygen therapy for patients with respiratory conditions.

Emergency oxygen supply in hospitals and ambulances.

2. Industrial Use:

Metal cutting, welding, and brazing.

Combustion processes in furnaces and kilns.

3. Commercial Use:

Aquaculture and fish farming.

Water treatment and purification.

In summary, an Oxygen Production Line with a Cylinders Filling System is a comprehensive setup designed to produce and distribute high-purity oxygen efficiently and safely. It involves a series of well-coordinated steps, from air intake and compression to purification and cylinder filling, ensuring a reliable supply of oxygen for various essential applications.Our strength lies in our ability to adapt our plants performances, safety and construction design philosophy to each project and customer’s specifications.

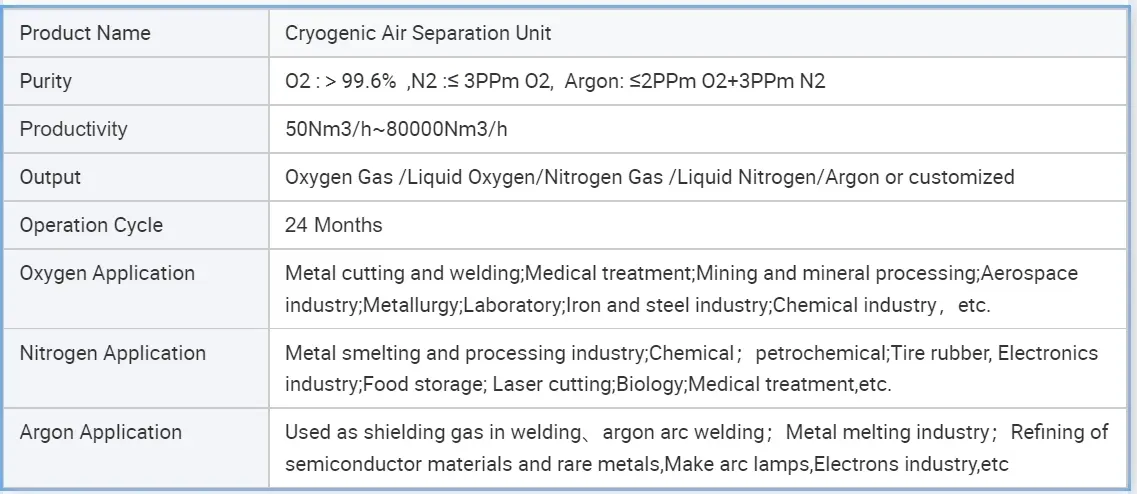

parameter

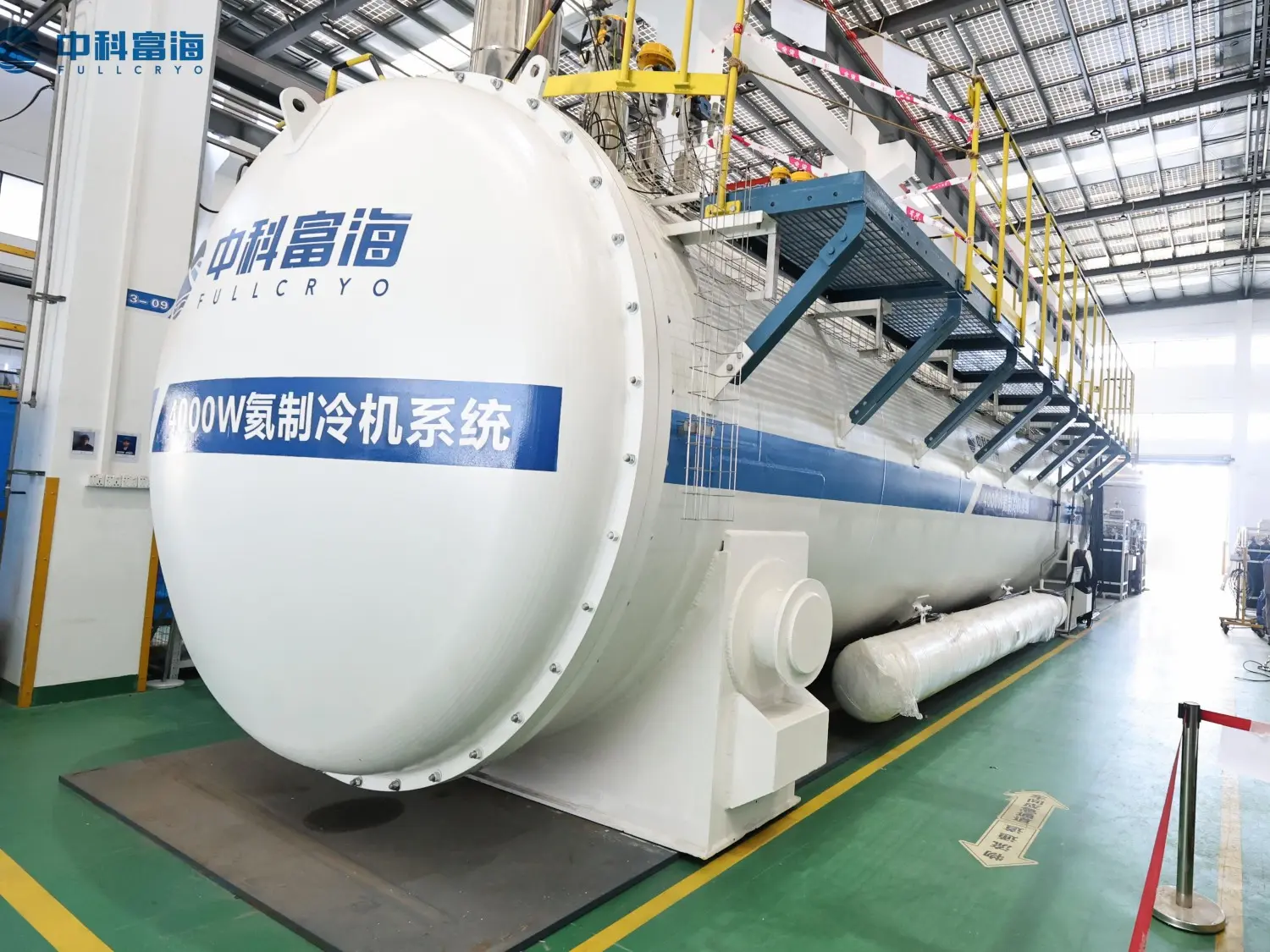

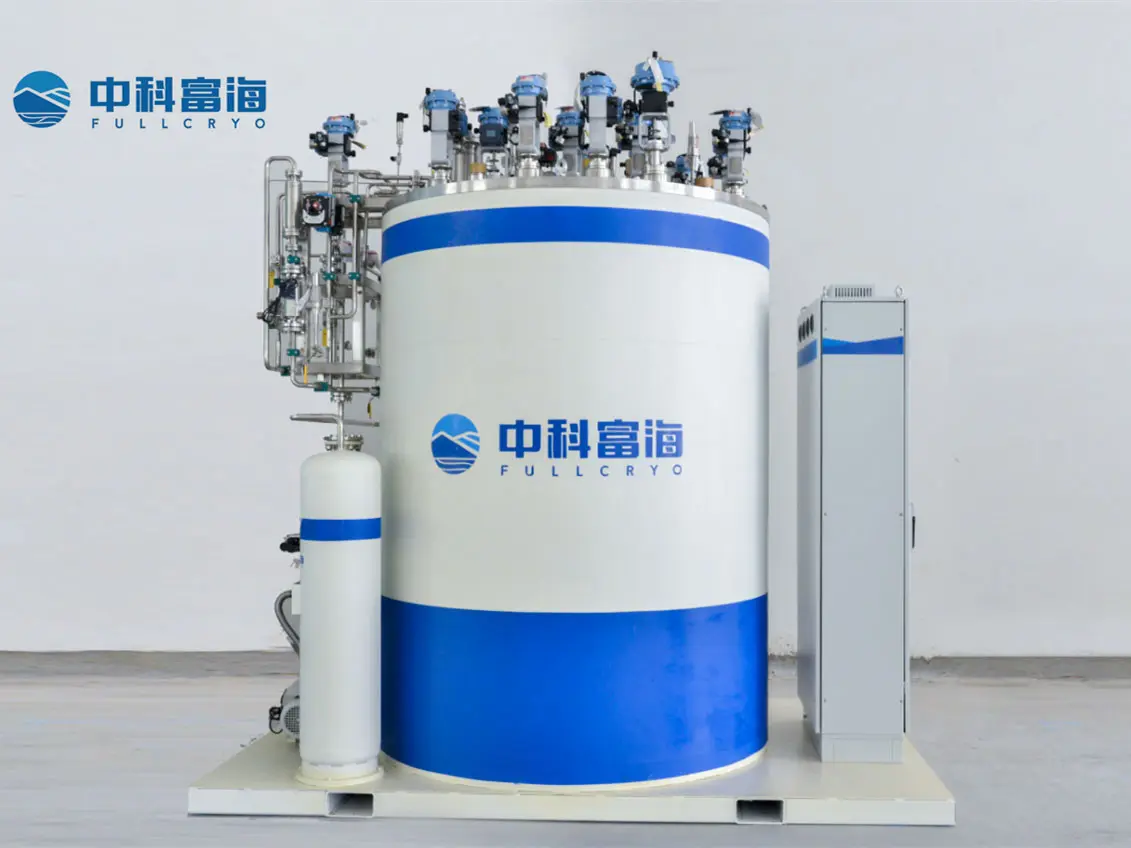

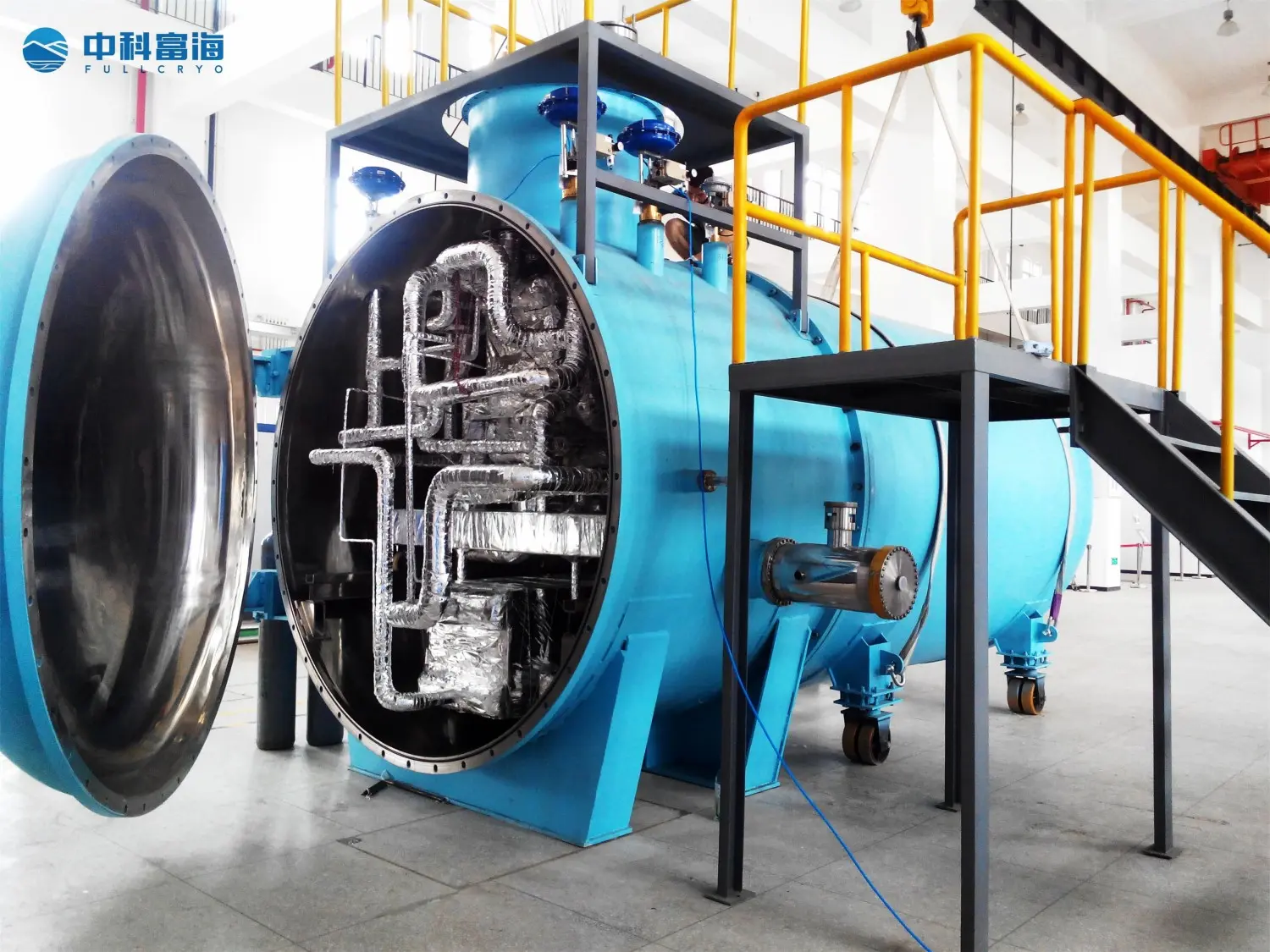

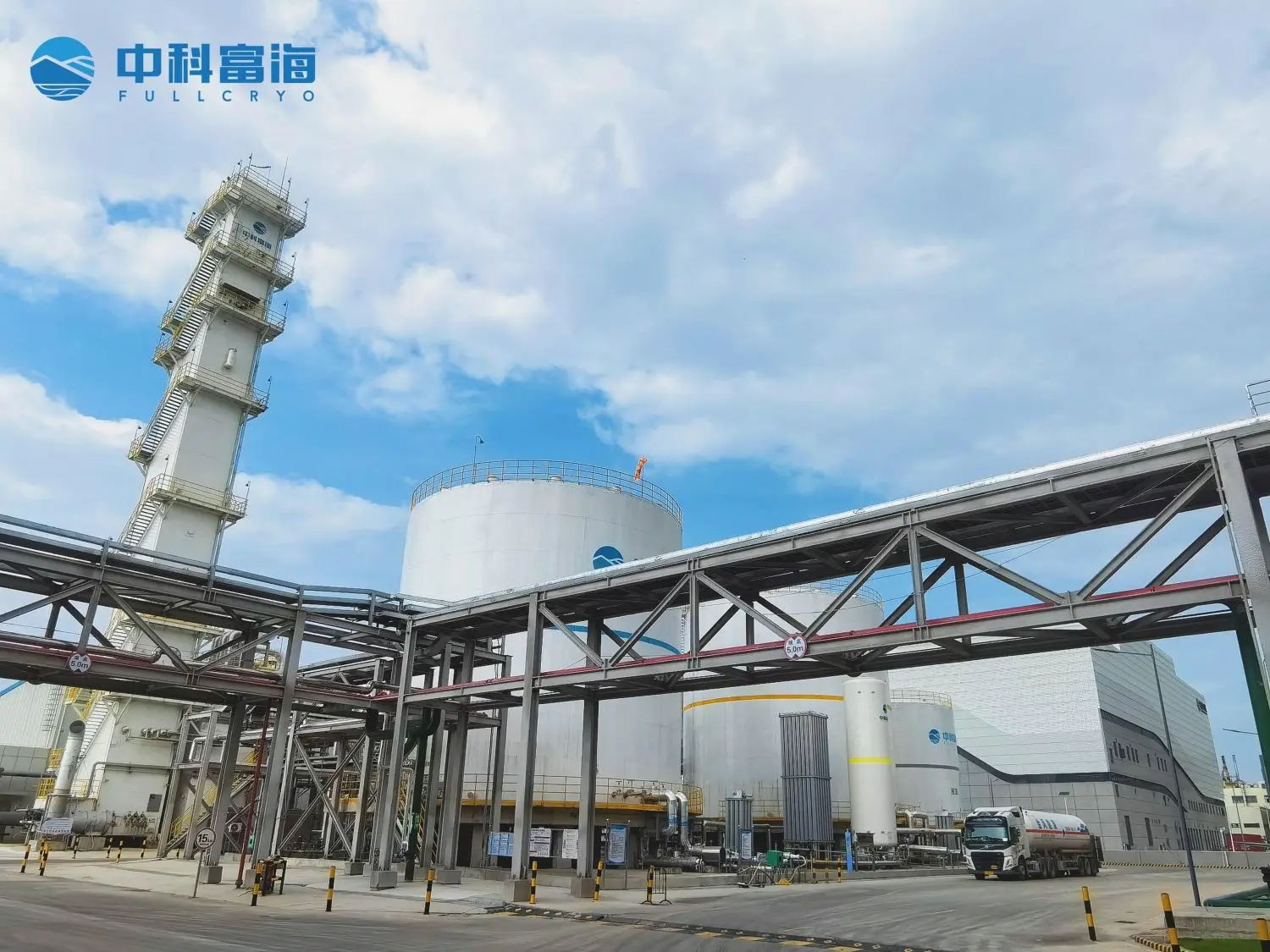

Factory Pictures