01

Oxygen Air Separation Plant For Metal Cutting and Welding

Product Description

An Oxygen Air Separation Plant designed for metal cutting and welding produces high-purity oxygen required for various industrial applications. Oxygen is crucial in these processes because it supports combustion and enables precise cutting and welding of metals. Here’s an overview of the plant's components and its function:

Role in Metal Cutting and Welding:

1. Oxy-Fuel Cutting:

Cutting Torch: Oxygen is used in conjunction with a fuel gas (such as acetylene, propane, or natural gas) in a cutting torch. The high-temperature flame generated melts the metal, and the oxygen stream oxidizes and blows away the molten metal, creating a precise cut.

Advantages: Provides clean, precise cuts with minimal slag and high cutting speed.

2. Welding:

Oxy-Acetylene Welding: Oxygen is mixed with acetylene to produce a high-temperature flame for welding. The flame melts the edges of the metal pieces, allowing them to fuse together as they cool.

Other Welding Processes: Oxygen is also used in various other welding processes, including plasma arc welding and gas tungsten arc welding (GTAW), to enhance combustion and improve weld quality.

3. Brazing and Soldering:

High-Temperature Flames: Oxygen-fuel combinations produce the high temperatures needed for brazing and soldering, processes that join metals by melting a filler metal into the joint.

Applications:

1. Industrial Fabrication: Used in manufacturing plants for cutting and welding metal components.

2. Construction: Employed in construction sites for structural steel cutting and welding.

3. Automotive and Aerospace: Essential for precise metal fabrication and repair work.

4. Maintenance and Repair: Used in various industries for maintenance and repair of metal equipment and structures.

Benefits:

1. Efficiency: High-purity oxygen ensures efficient combustion, leading to faster cutting and welding operations.

2. Quality: Precise control over the oxygen supply results in cleaner cuts and stronger welds.

3. Cost-Effectiveness: Efficient oxygen use reduces fuel consumption and operational costs.

4. Safety: Properly designed and maintained oxygen systems minimize risks associated with high-pressure gas handling.

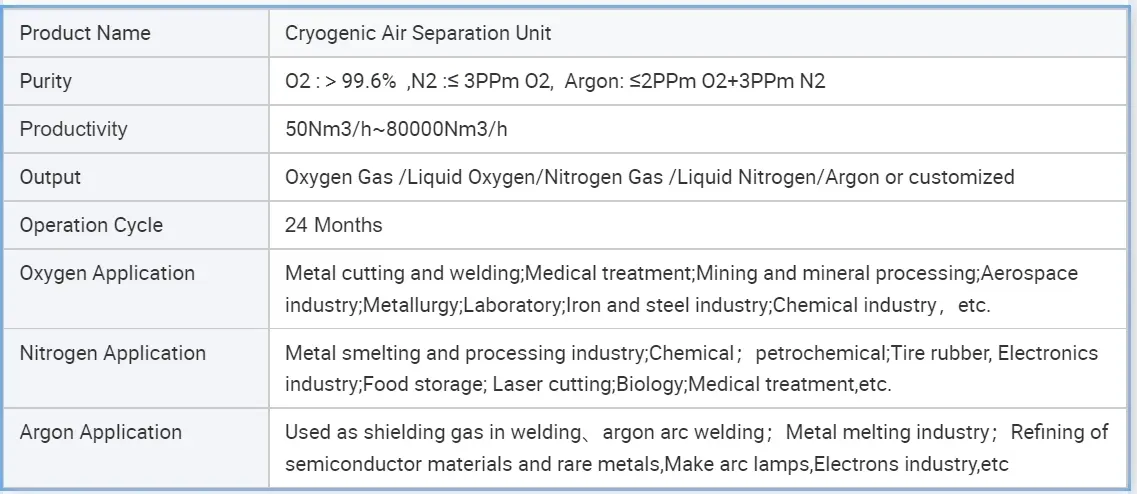

parameter

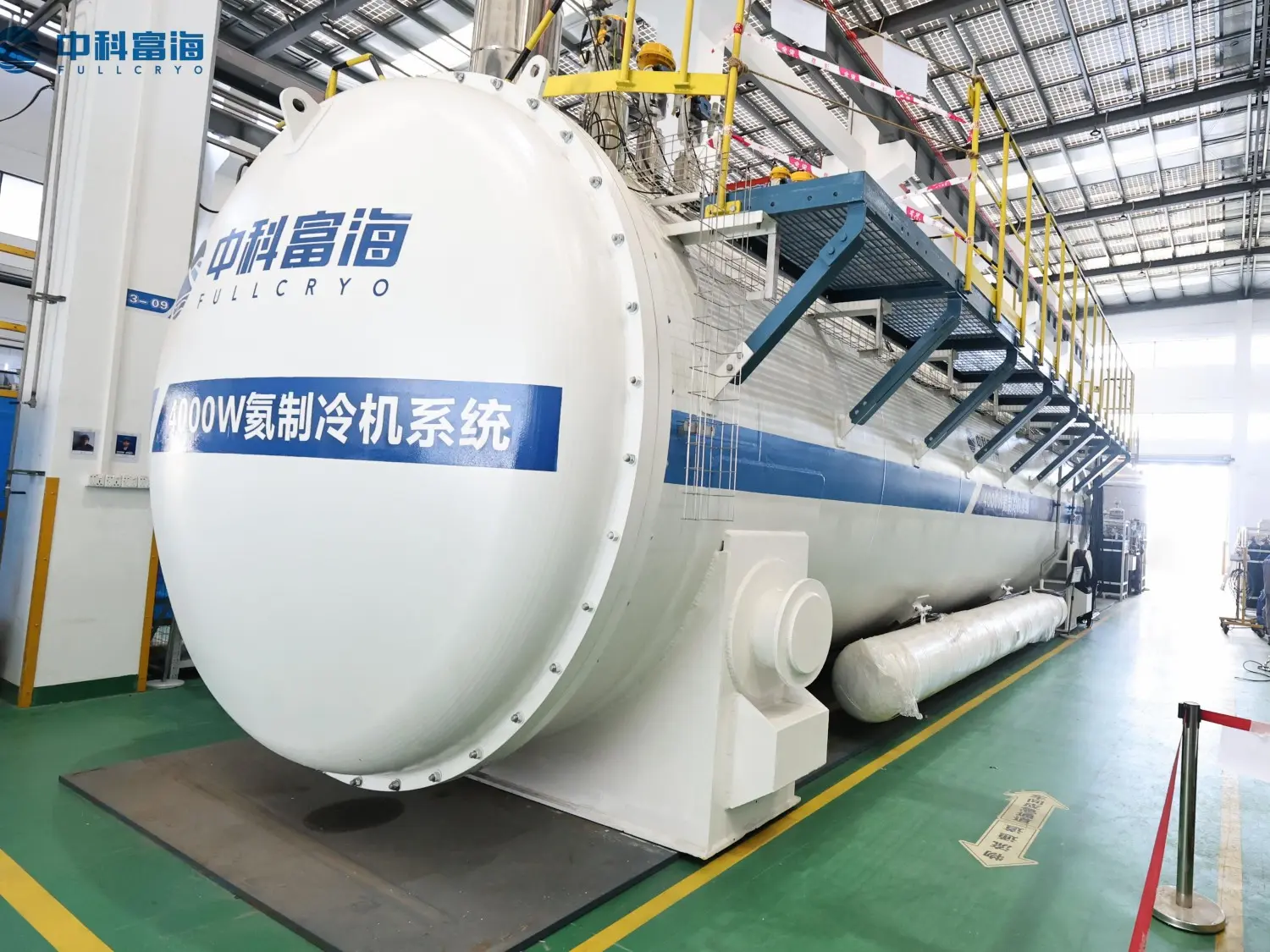

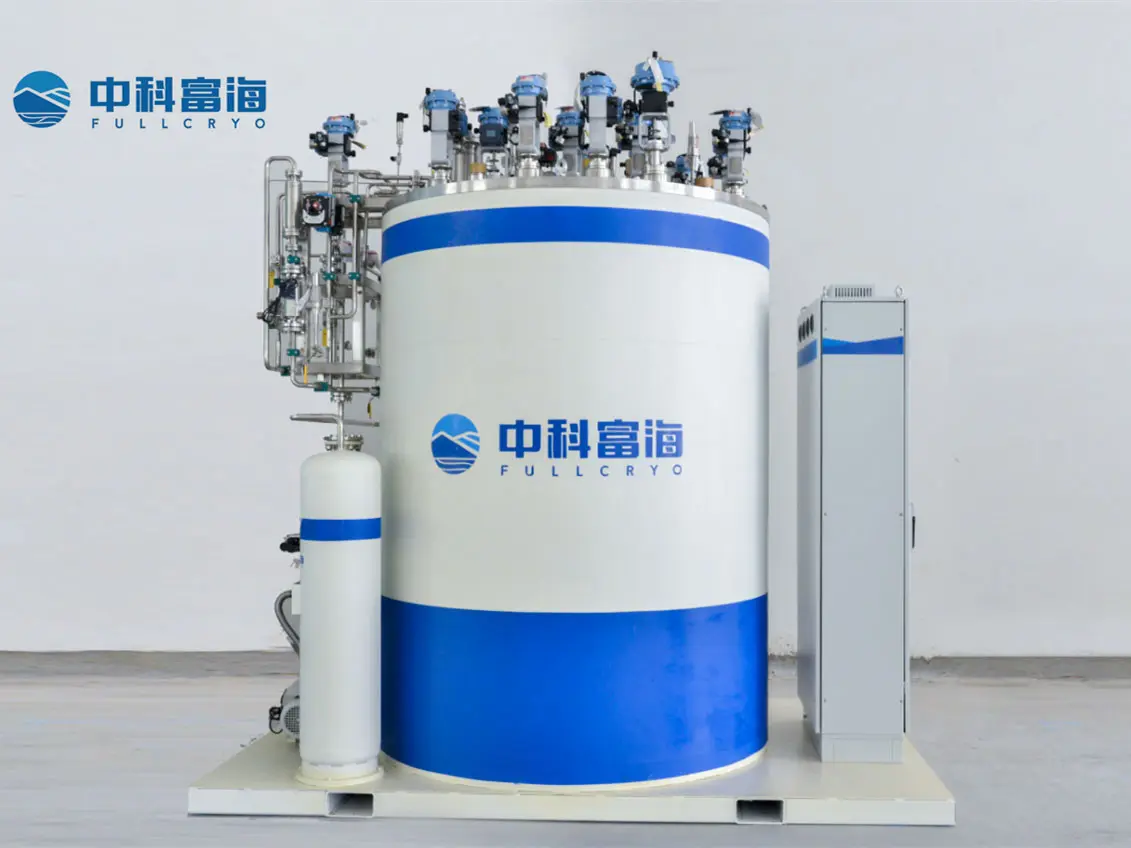

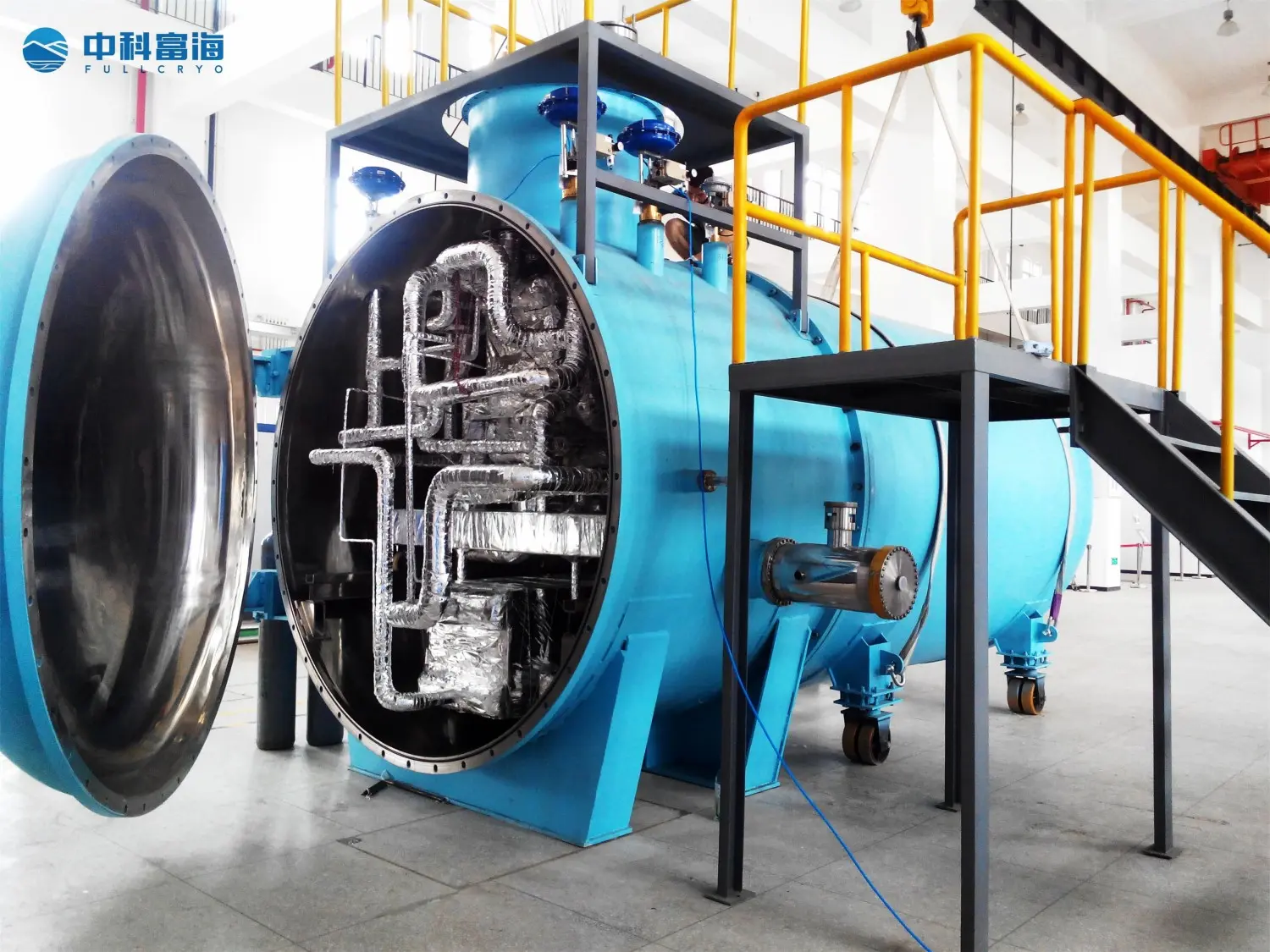

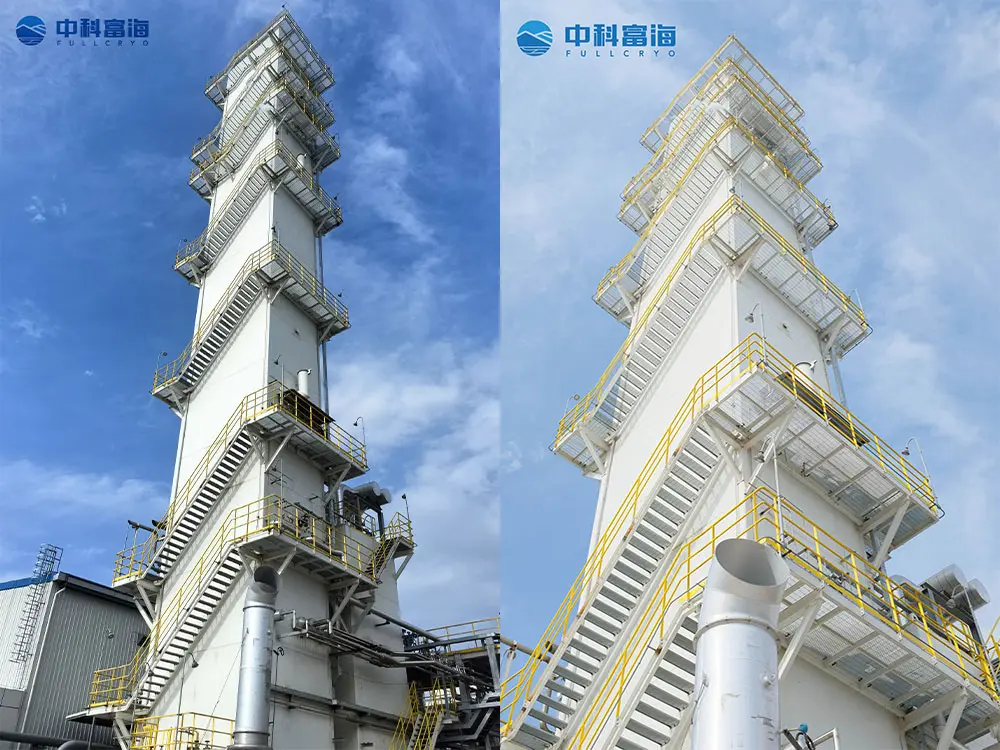

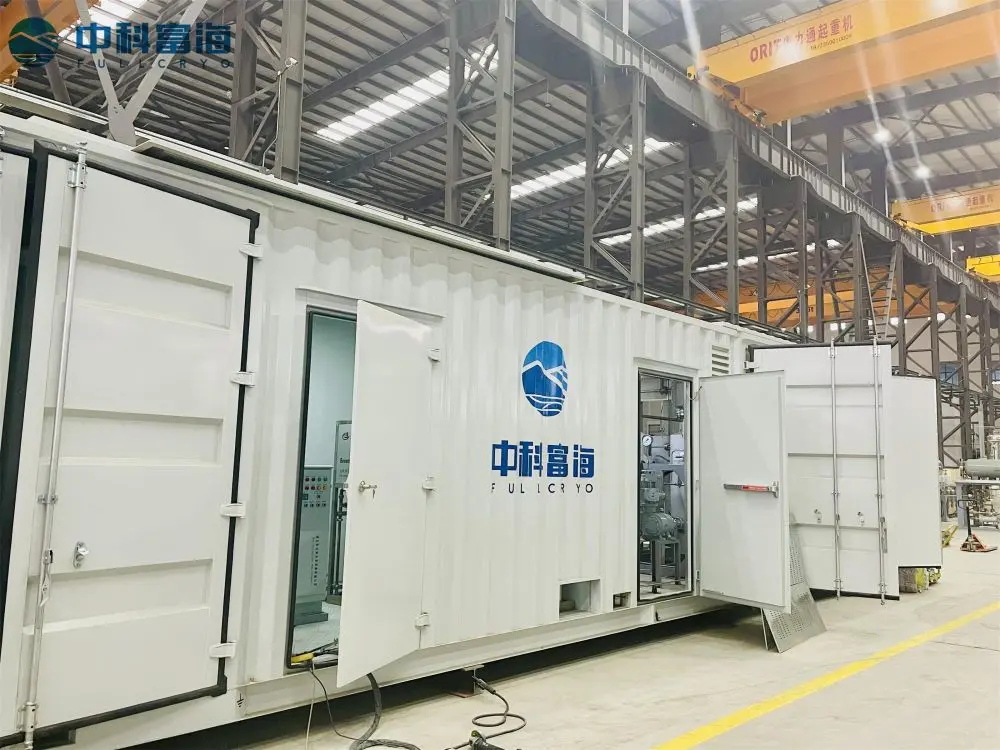

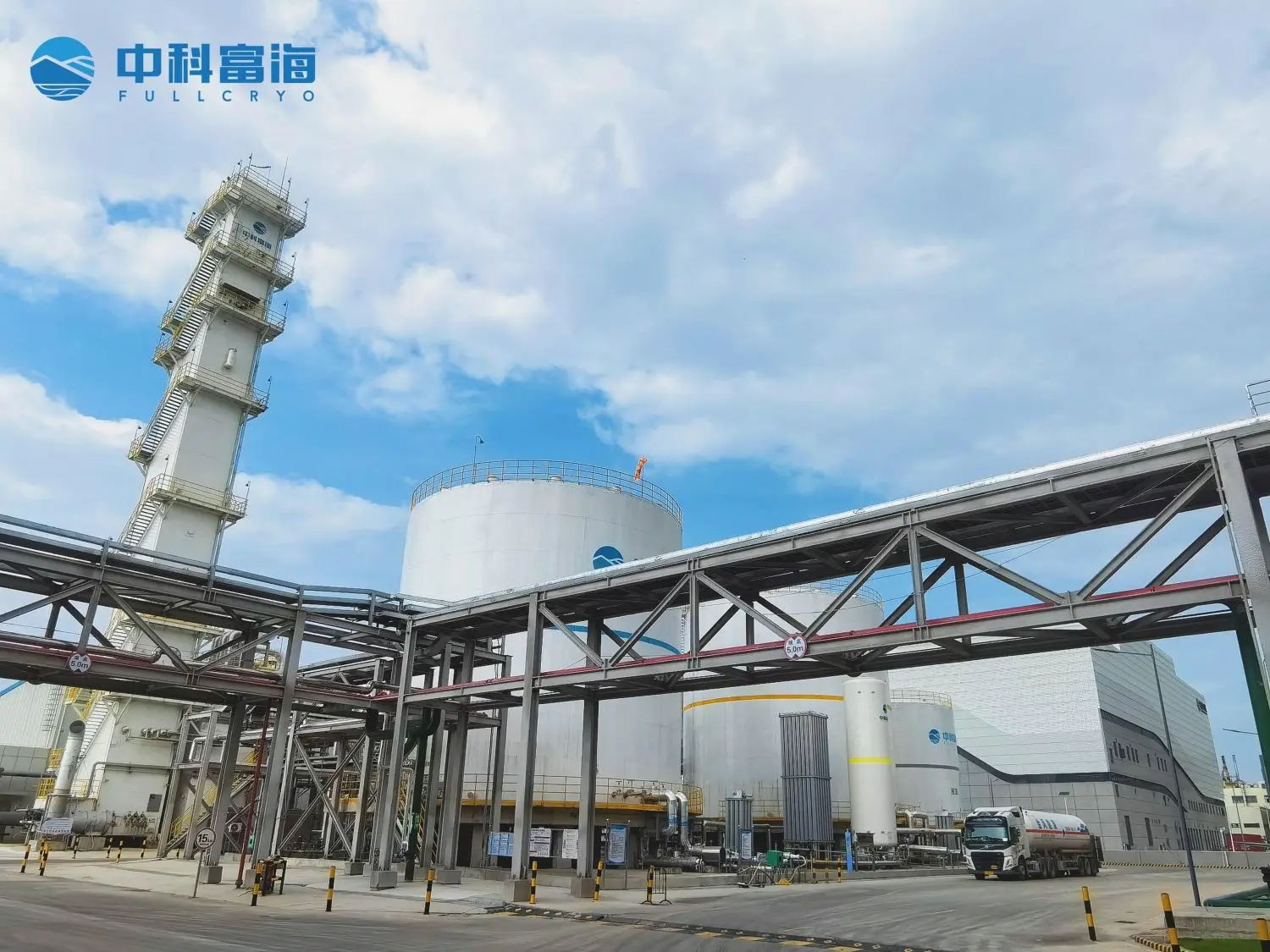

Factory Pictures