01

LOX LIN LAr Air Separate Unit Provider

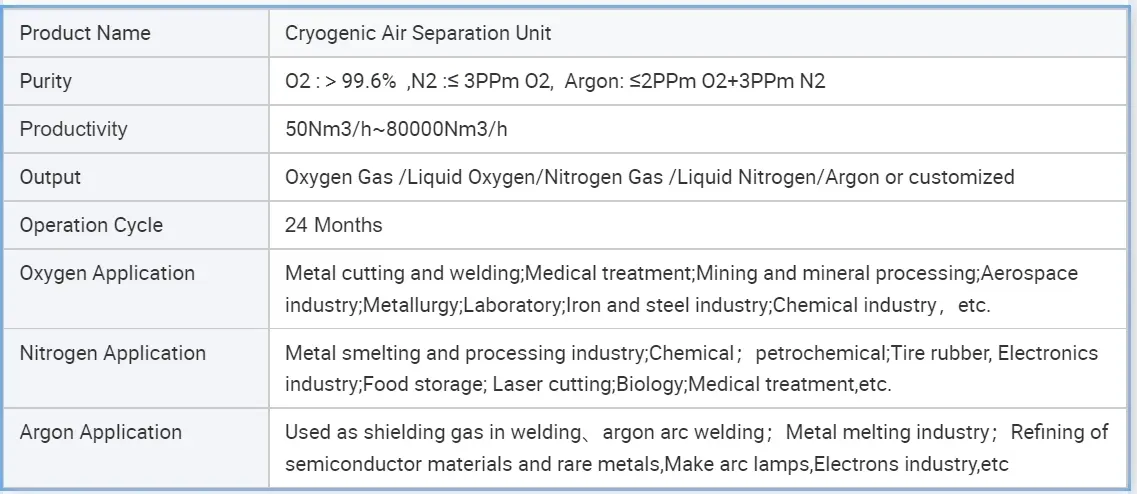

Product Description

LOX, LIN and LAr refer to liquid oxygen, liquid nitrogen and liquid argon respectively. An air separation unit (ASU) is a facility that produces these gases through a cryogenic air separation process.

In an air separation unit, air is compressed and then cooled to a very low temperature, causing it to liquefy. The liquefied air is then separated into its main components using a distillation column. The process produces high-purity liquid oxygen, liquid nitrogen and liquid argon that can be stored and distributed for a variety of industrial, medical and scientific applications.

Liquid oxygen is used in respiratory support in medical facilities, in industrial processes such as metal cutting and welding, and in the production of chemicals and fuels. Liquid nitrogen is used in food packaging, electronics manufacturing, and as an inert gas for purges and blankets. Liquid argon is used as a shielding gas in welding, metal fabrication, and the production of specialty metals.

Overall, the production of LOX, LIN, and LAr via ASU is critical to meeting the diverse needs of industries and applications that rely on these liquid gases.

Technological process flow:

1 . Impurity purification system: mainly through the air filter and molecular sieve absorber device, purification air mixed with mechanical impurities, water, carbon dioxide, acetylene and so on.

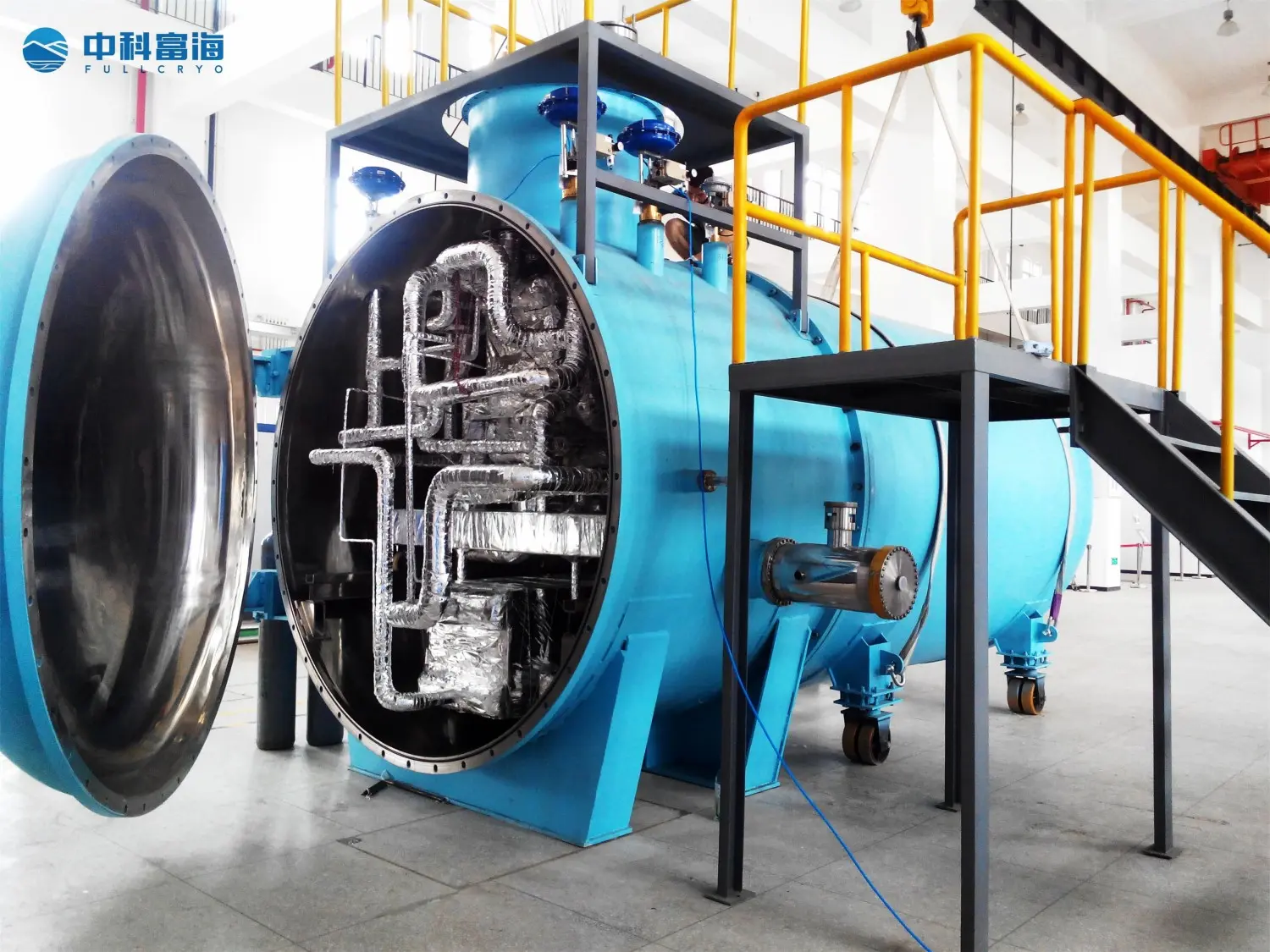

2 . Air cooling and liquefaction system: mainly composed of air compressor, heat exchanger, expander and air throttle valve, play the role of deep freezing air.

3 . Air rectification system: the main components are rectifying column (upper tower, lower tower), condensing evaporator,subcooler, liquid air and liquid nitrogen throttle valve.

4 . Heating and blowing system: The purification system is regenerated by heating and blowing.

5 . Instrument control system: control the whole process through various instruments.

Fullcryo specializes in industrial gas solutions,emphasizes energy efficiency and compliance with global standards.Known for sustainability, high-quality standards, and extensive support.

parameter

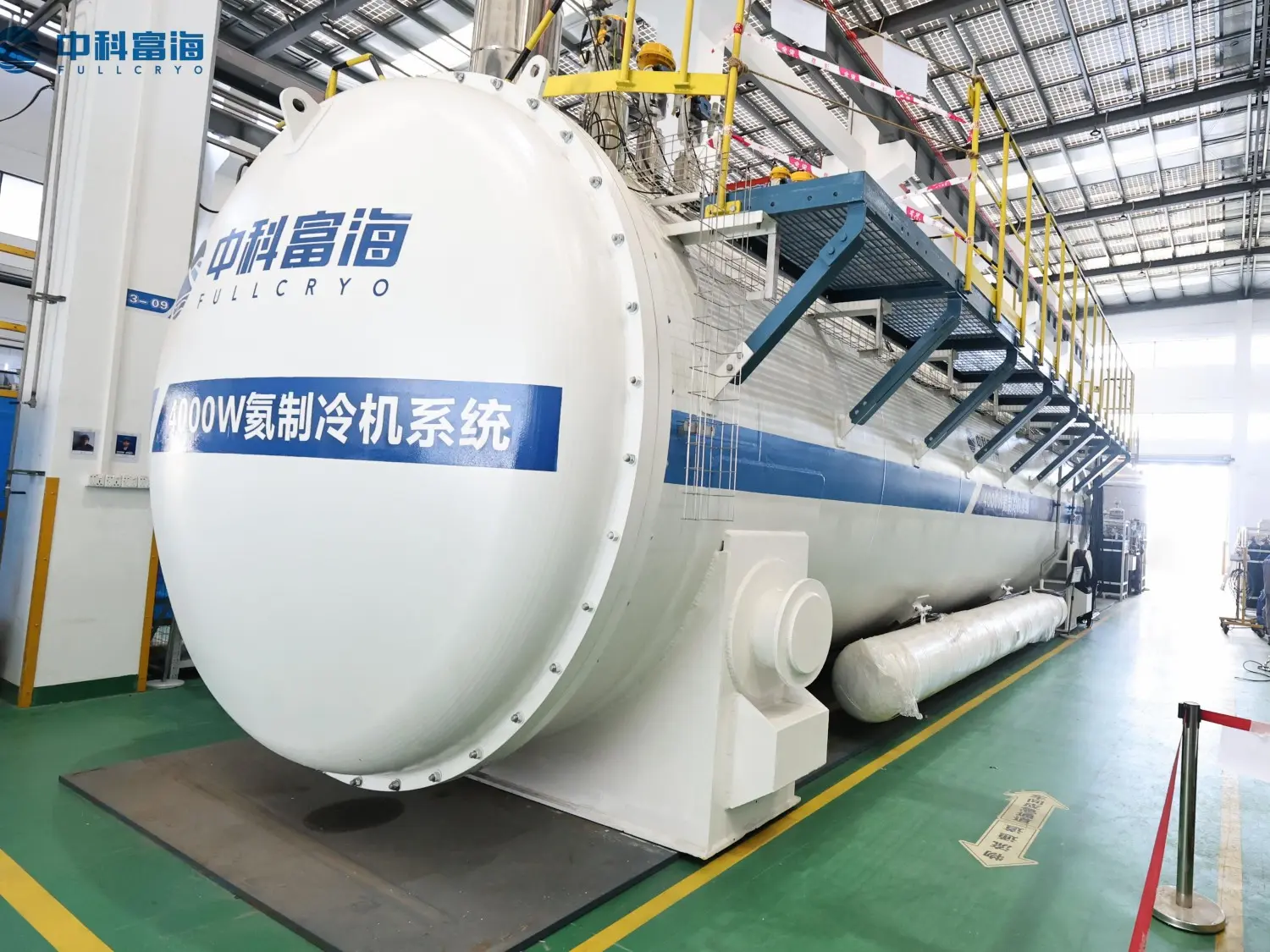

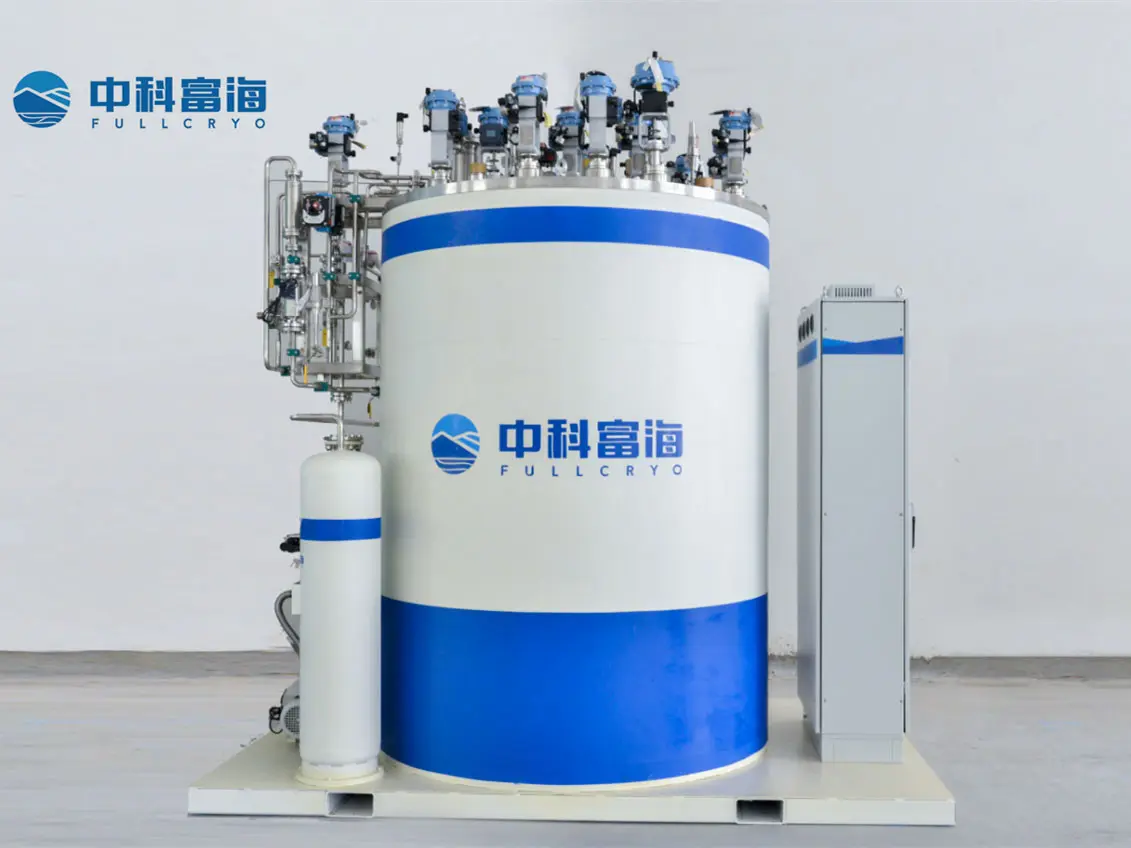

Factory Pictures