01

Liquid Oxygen Air Separation Equipment Manufacturer

Product Description

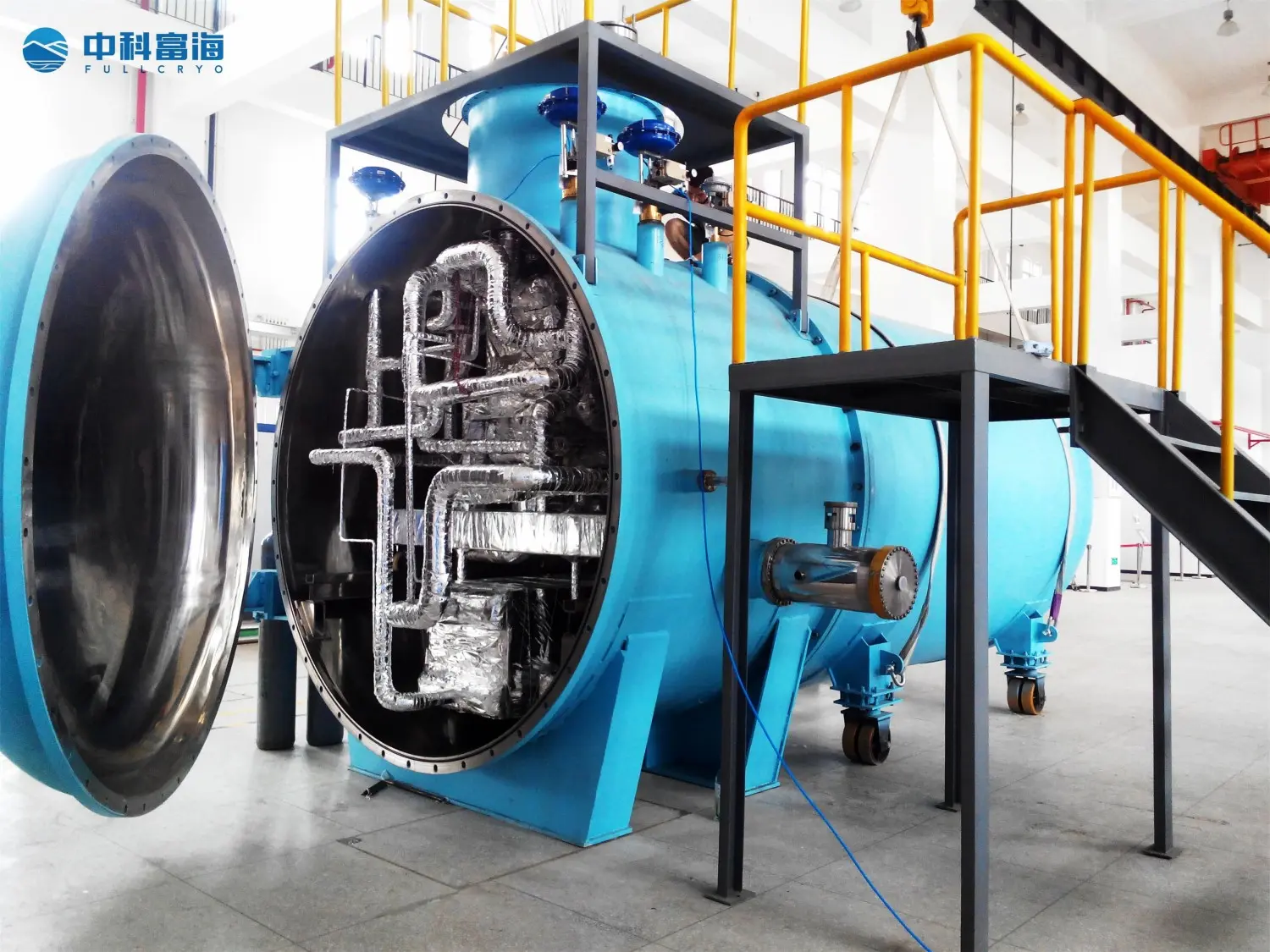

Differ from Pressure swing adsorption process (PSA) process, Fullcryo adopt Cryogenic distillation process for making the air separation plant.

With this process, pure gases can be separated from air by first cooling it until it liquefies, then selectively distilling the components at their various boiling temperatures. It can produce high purity gas product.

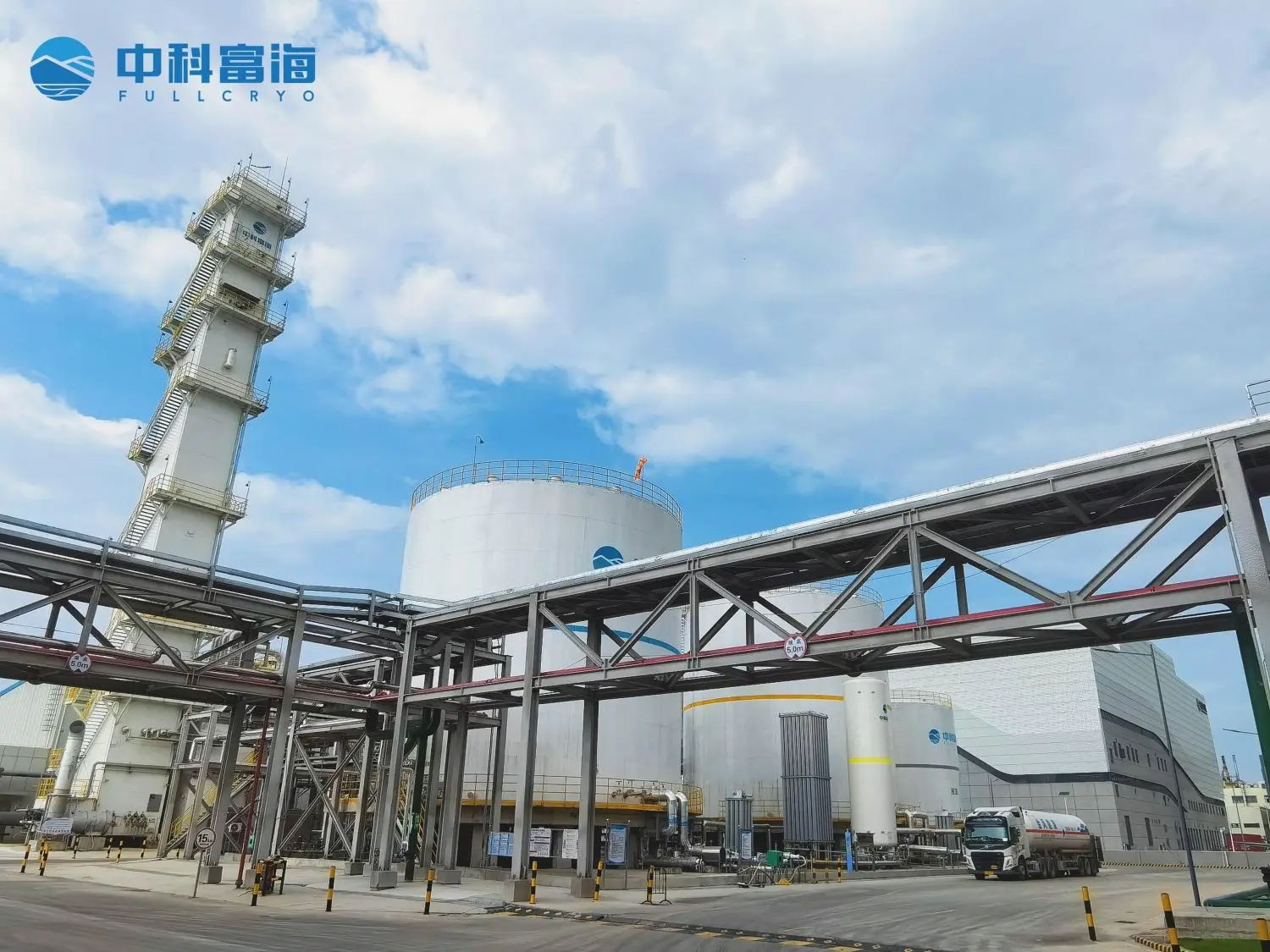

Fullcryo have the experience, flexibility and capacity to provide a wide range of air separation units through standard plants, customized offerings and other cryogenic liquefaction technologies.

Key Considerations When Choosing a Manufacturer:

1. Technology and Innovation:

Ensure the manufacturer uses advanced technology that guarantees high purity and efficiency in oxygen production.

Look for innovation in cryogenic distillation processes and energy efficiency.

2. Customization and Scalability:

The manufacturer should offer customizable solutions to meet specific requirements regarding capacity, purity levels, and application needs.

Consider whether the equipment can be scaled up or down based on future production demands.

3. Quality and Compliance:

Verify that the equipment complies with international standards such as ISO 9001 (Quality Management) and relevant safety and environmental regulations.

Check for certifications and quality assurance processes that ensure reliability and durability.

4. Support and Maintenance Services:

The manufacturer should provide comprehensive support, including installation, commissioning, training, and after-sales services.

Ensure they offer regular maintenance, technical support, and spare parts availability.

5. Reputation and Experience:

Research the manufacturer’s reputation in the industry, including customer reviews, case studies, and project history.

Consider the experience and expertise in producing ASUs for similar applications and industries.

6. Cost and Value:

Evaluate the overall cost, including initial investment, operational costs, and potential savings from efficiency and reliability.

Consider the value provided in terms of technology, support, and long-term benefits.

By carefully selecting a reputable manufacturer and ensuring they meet your specific needs, you can achieve a reliable and efficient liquid oxygen production system that supports your operations effectively.

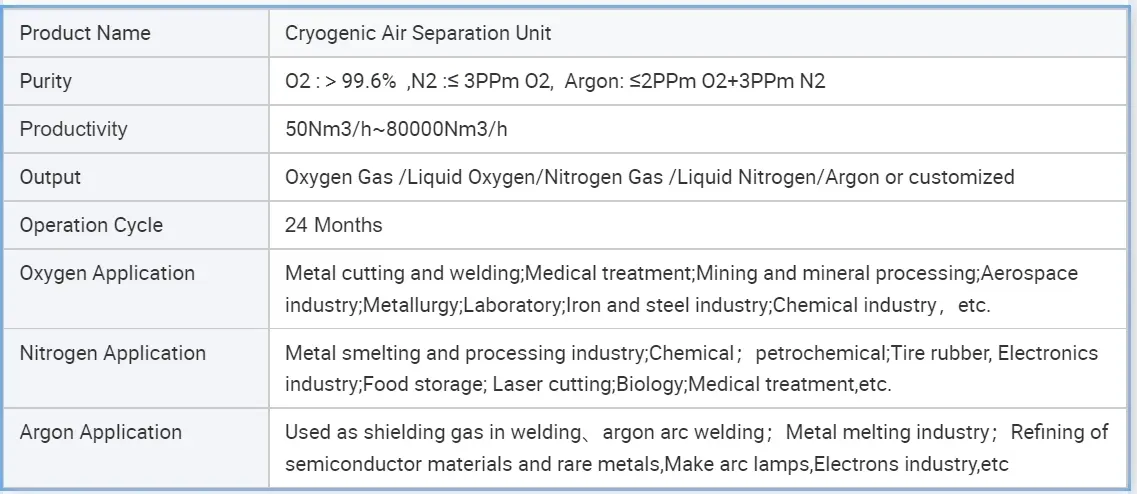

parameter

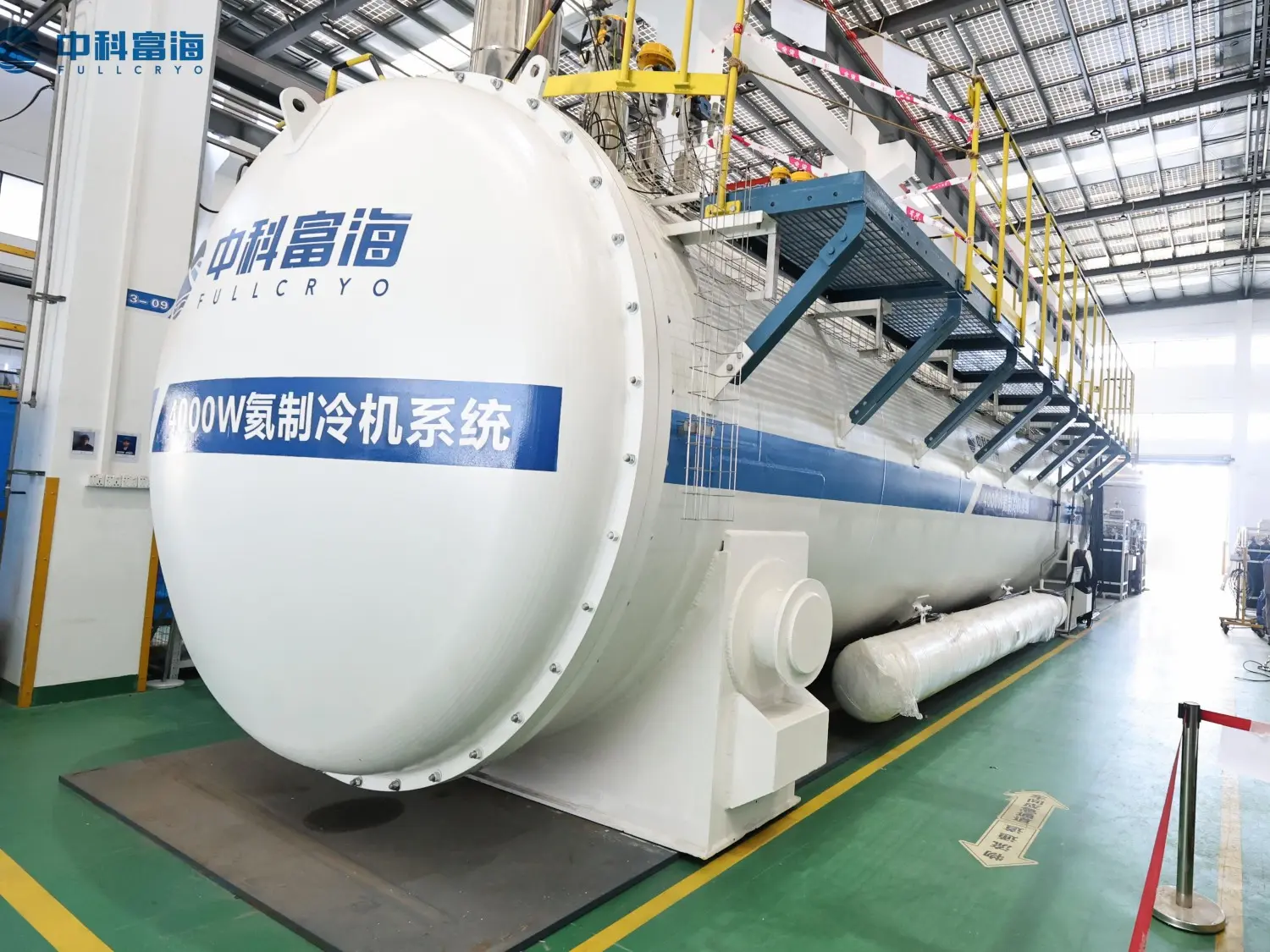

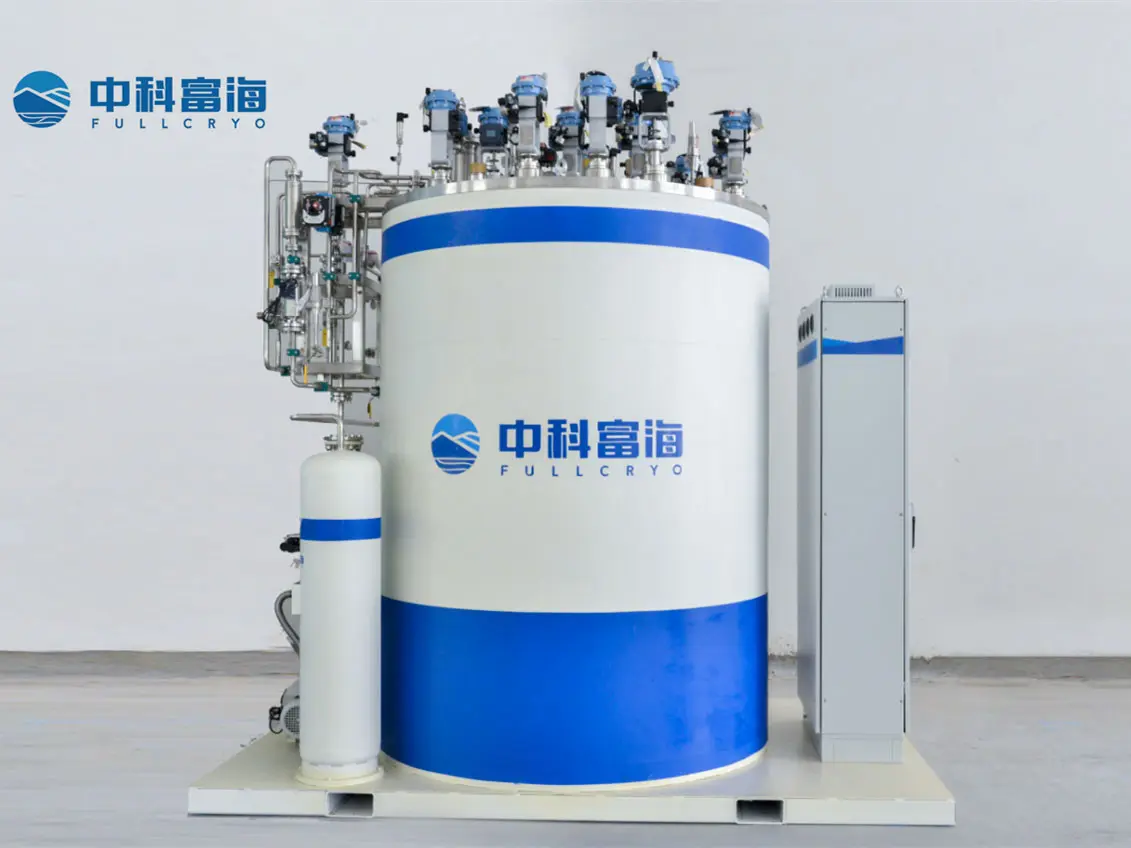

Factory Pictures