01

High Purity Medical Grade Oxygen Plant

Product Description

A High Purity Medical Grade Oxygen Plant is a specialized facility designed to produce oxygen with a high level of purity, typically 99.5% or higher, to meet stringent medical standards for use in healthcare settings. Here’s a brief overview of its key components and functions:

1.Air Intake and Filtration:

Ambient air is drawn into the plant through air intake filters, which remove large particles and contaminants.

2.Compression:

The filtered air is compressed using air compressors to increase the pressure, which is essential for the subsequent separation process.

3.Cooling and Purification:

The compressed air is then cooled to remove moisture and further purified to eliminate impurities such as carbon dioxide, hydrocarbons, and other contaminants using molecular sieves or adsorption methods.

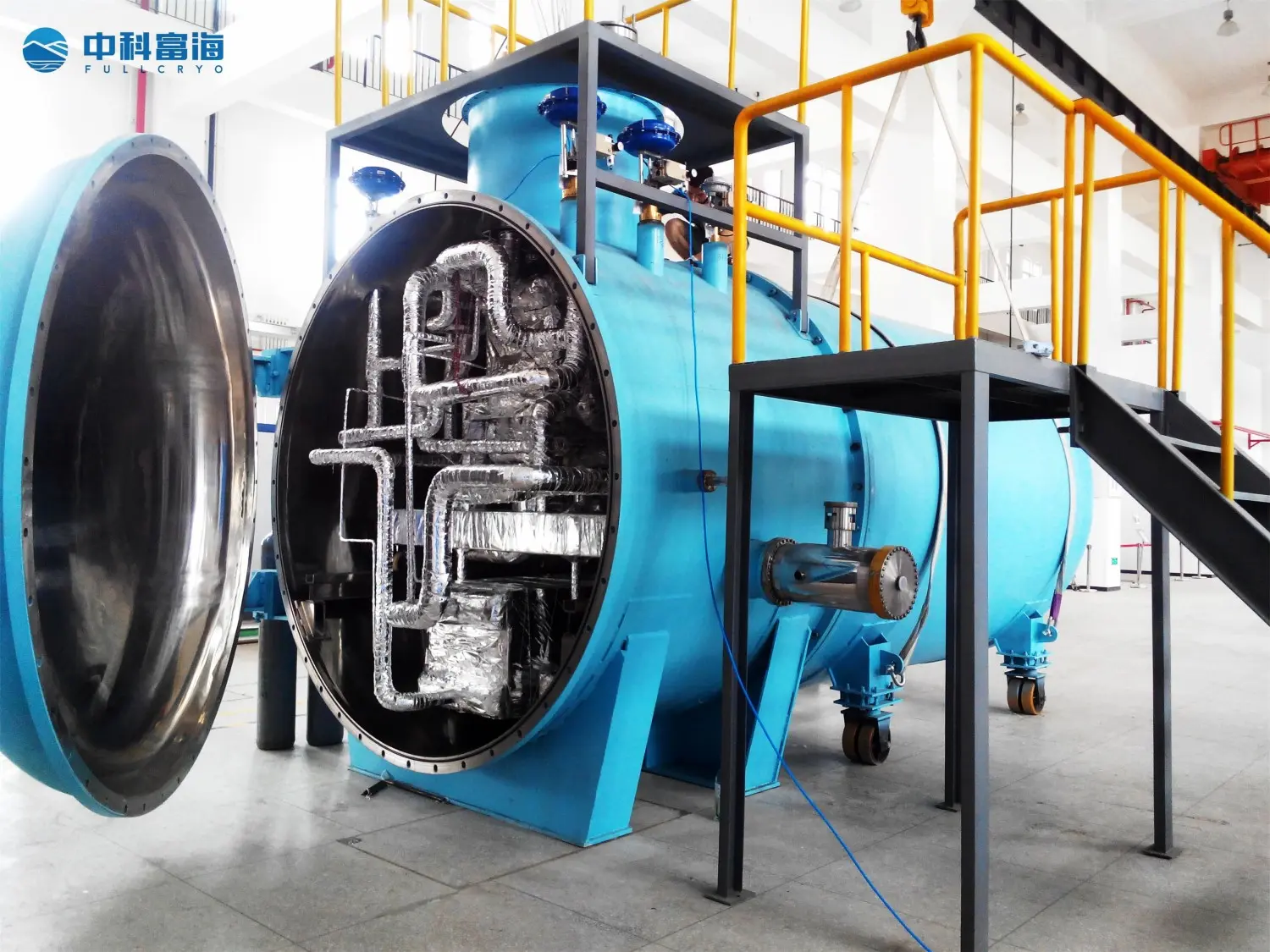

4.Cryogenic Separation:

The purified air is cooled to cryogenic temperatures in a heat exchanger, causing it to liquefy. The liquefied air is then fed into a distillation column where it is separated into its components (mainly oxygen and nitrogen) based on their different boiling points.

5.Oxygen Purification:

The separated oxygen is further purified to ensure it meets medical-grade standards, achieving a purity level of 99.5% or higher.

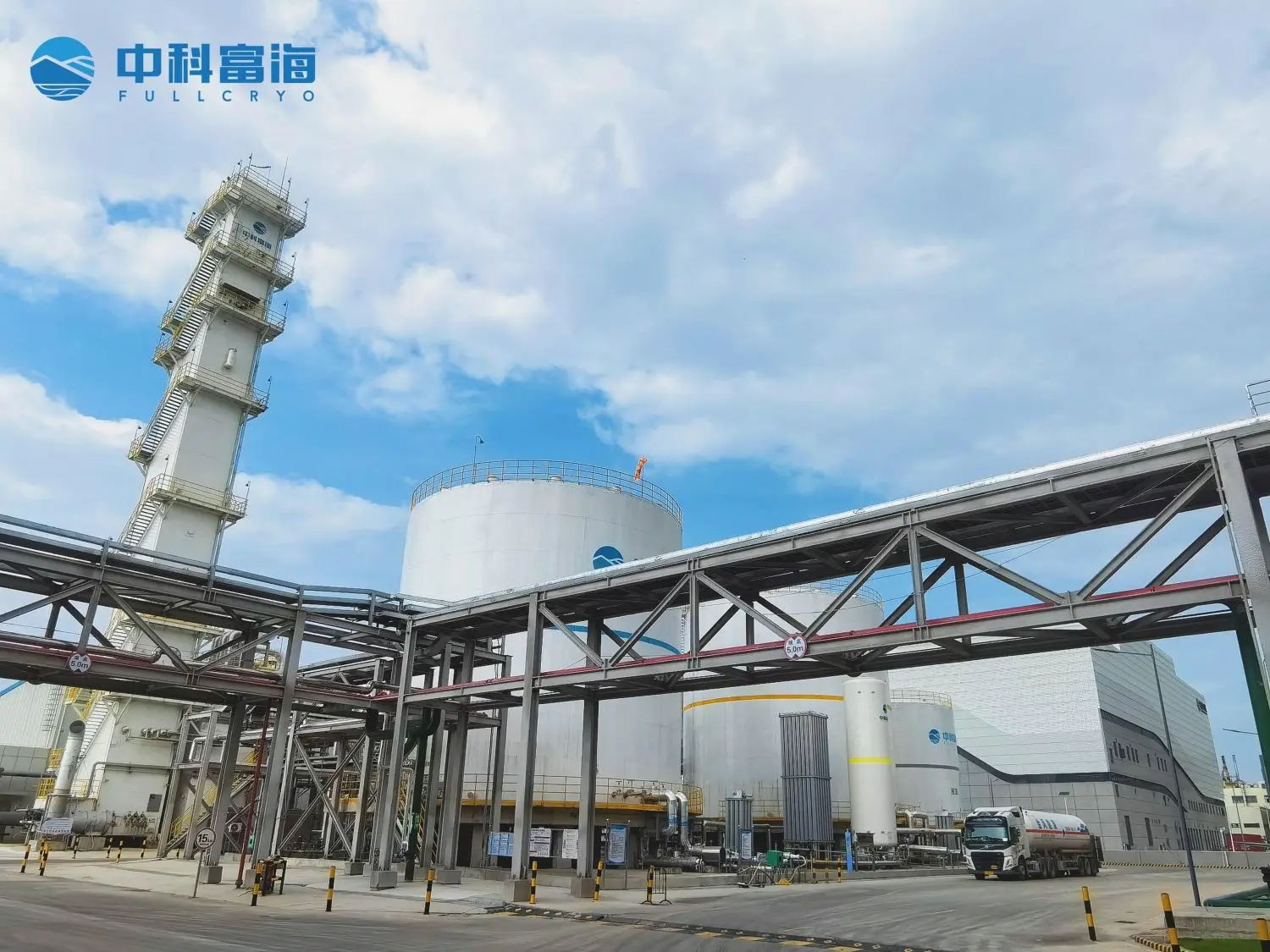

6.Storage and Distribution:

The high-purity oxygen is then compressed and stored in high-pressure cylinders or cryogenic tanks for distribution. In hospitals, the oxygen is often delivered directly through a pipeline system.

7.Quality Control:

The oxygen produced is rigorously tested to ensure it meets medical standards, with continuous monitoring for purity, pressure, and flow rates to guarantee safe and reliable delivery to patients.

8.Regulatory Compliance:

The plant operates in compliance with regulatory standards set by health authorities (such as the FDA, European Medicines Agency, or local health departments) to ensure the oxygen produced is safe for medical use.

The high-purity medical-grade oxygen produced by these plants is essential for various medical applications, including respiratory therapy, anesthesia, life support, and critical care in hospitals and clinics.

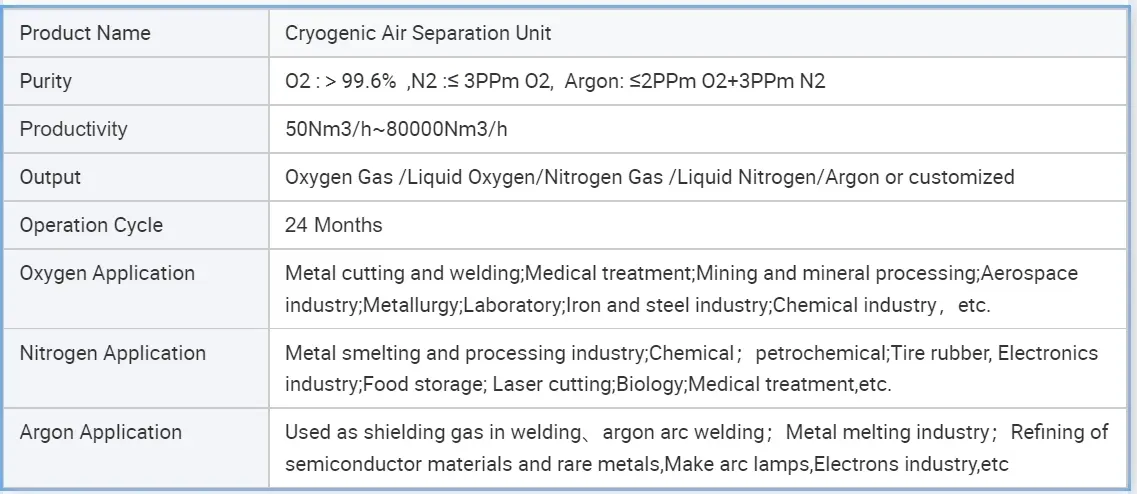

parameter

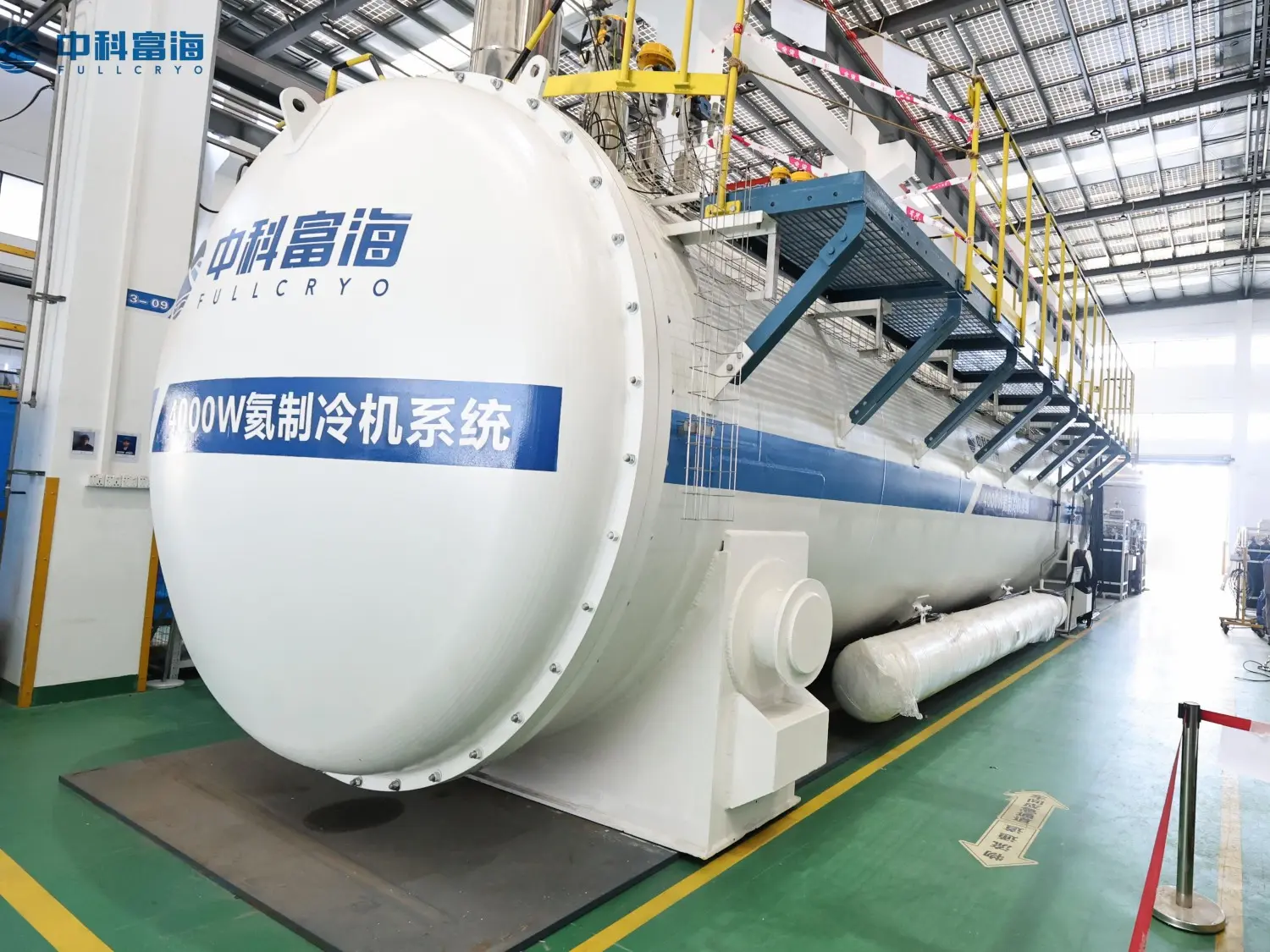

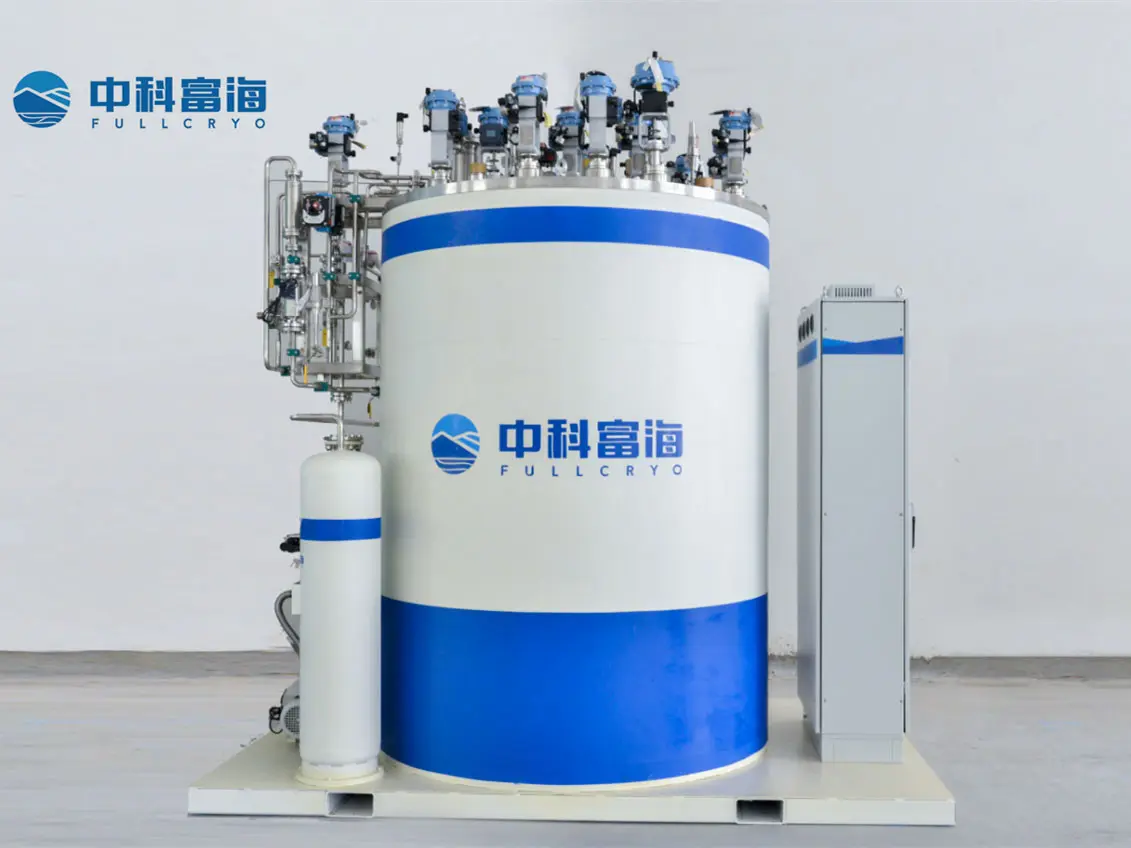

Factory Pictures