0102030405

FULLCRYO VPSA Oxygen Generation Plant For Glass Fiber Industry

Product Description

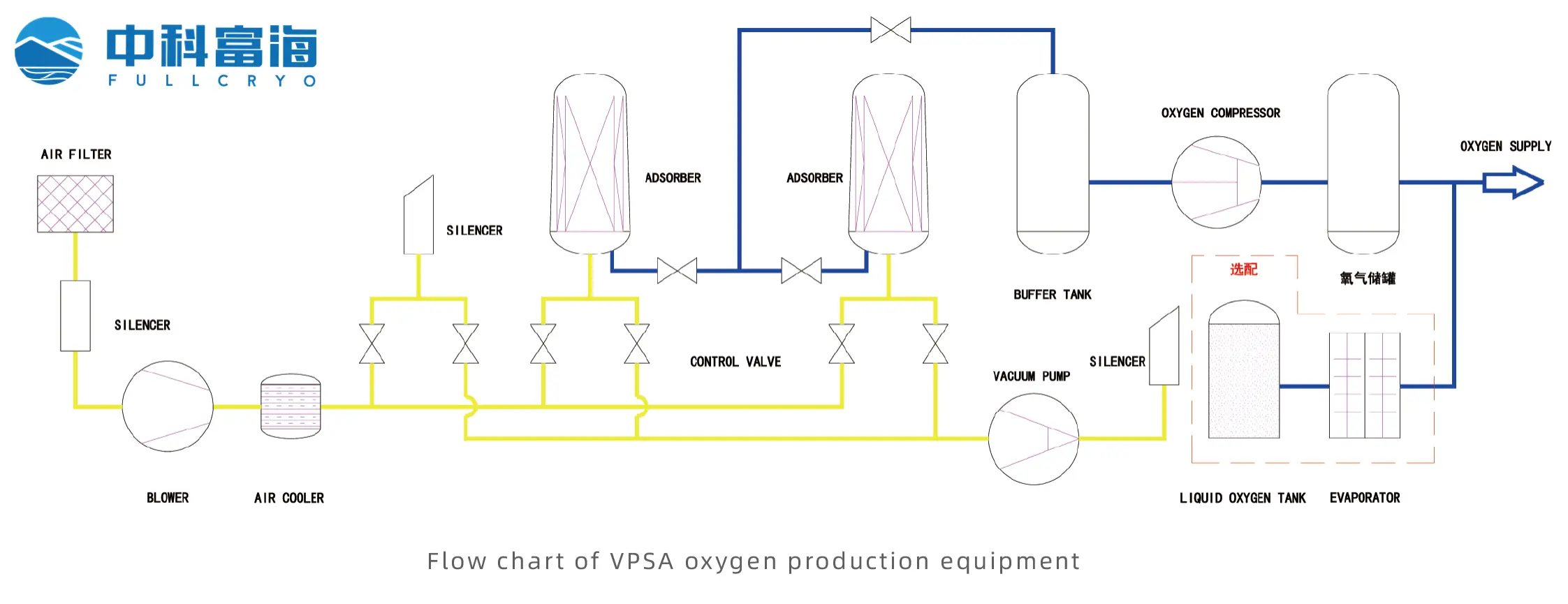

A VPSA (Vacuum Pressure Swing Adsorption) Oxygen Generation Plant is an advanced system designed to produce high-purity oxygen efficiently. In the glass fiber industry, oxygen is crucial for various processes, including combustion in glass melting furnaces, which enhances production efficiency, reduces fuel consumption, and improves product quality. Here’s a detailed overview of a VPSA oxygen generation plant tailored for the glass fiber industry:

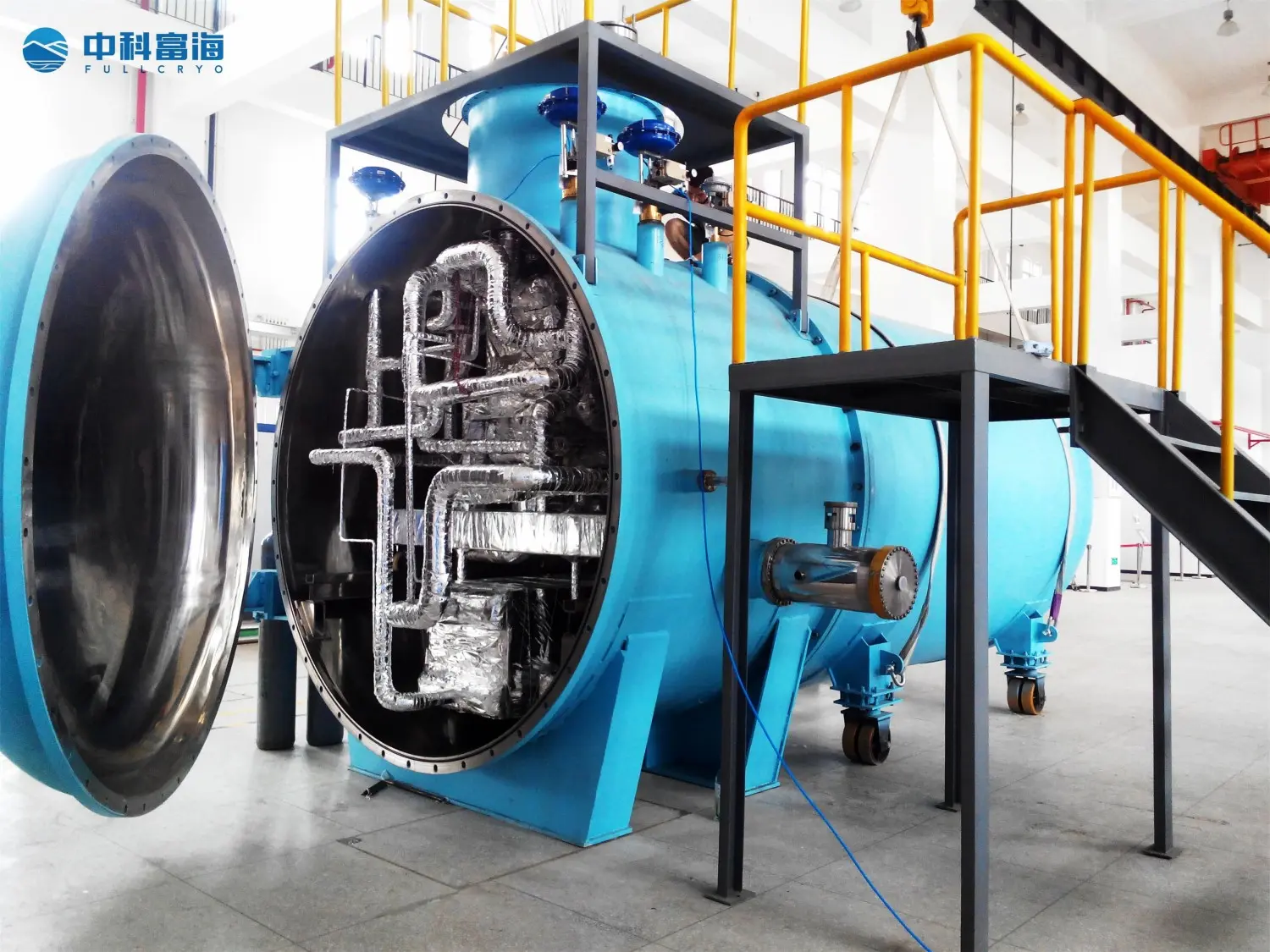

The technical foundation of radial tower comes from the most advanced enterprises abroad.Combined with the research of Fullcryo in the field of adsorption for many years,The air flow distribution between the upper and lower parts of the adsorption tower,the opening rate of the orifice plate,the shape of the opening,the ratio of the transfer layer,the size of the filling barrel and so on are studied.Optimize the simulation and adjust or fine-tune a number of parameters.Especially for high-concentration products,such as oxygen-enriched products with a stable concentration of more than 90%in the glass fiber industry,The thickness of the transfer layer and the size of the inner cylinder are different from those of the traditional 90%concentration.The serial number of this patent issued by the State Patent Office is 2023040200027710.

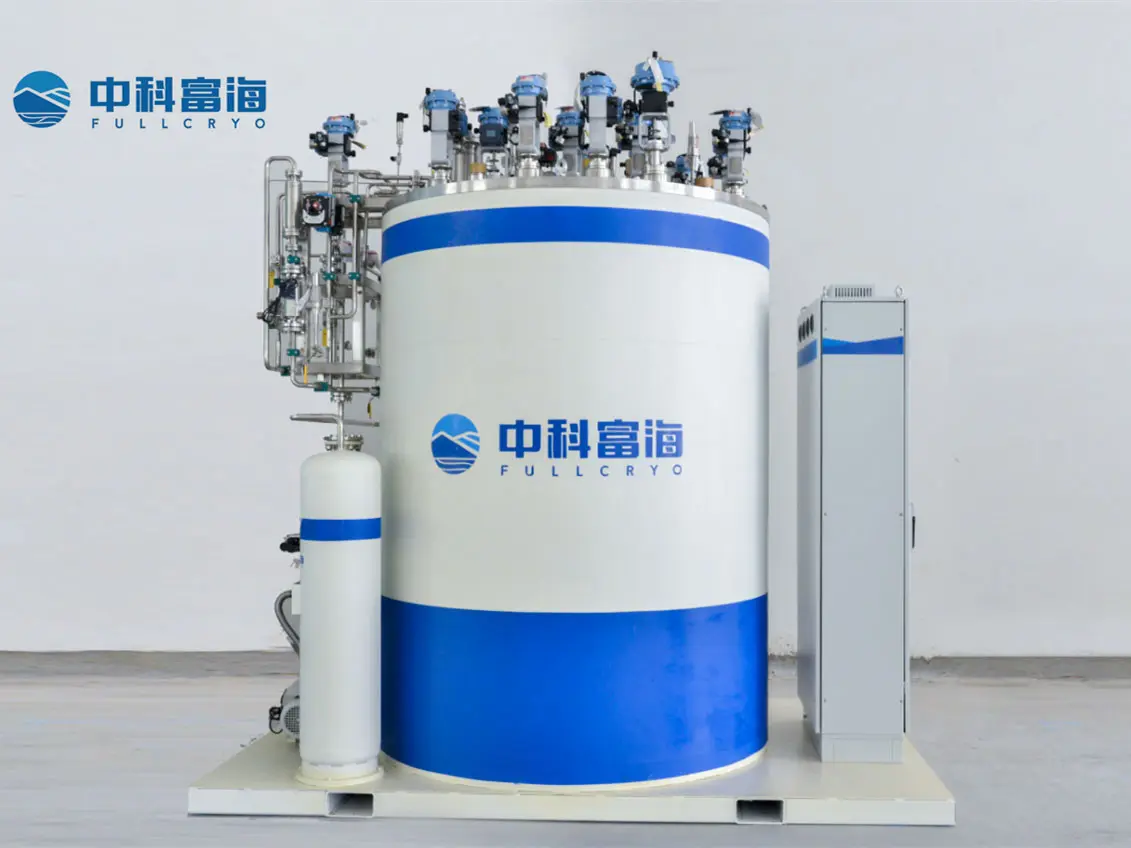

Compared to other companies using the radial column process,Fullcryo has its own equipment manufacturing company(Fullcryo(Zhongshan)Low Temperature Equipment Manufacturing Co.,Ltd.).It has a more standardized plant and production environment,and its own quality management system ensures the quality of the adsorption tower.

parameter

| Model | FHOX-2000 | FHOX-3000 | FHOX-5000 | FHOX-6500 | FHOX-7500 |

| Oxygen flow | 2000Nm³/h | 3000Nm³/h | 5000Nm³/h | 6500Nm³/h | 7500Nm³/h |

| Equipment footprint | 25*15m | 28*24m | 36*24m | 48*50m | 48*52m |

| Oxygen purity | 80%~95%(adjustable) | ||||

| Oxygen outlet pressure | Customized | ||||

| Device start-up time | ≤20min | ||||

| Continuous operation cycle | ≥2 years | ||||

| Load adjustment range | 30%~100% | ||||

| Adsorbent service life | ≥10 years | ||||

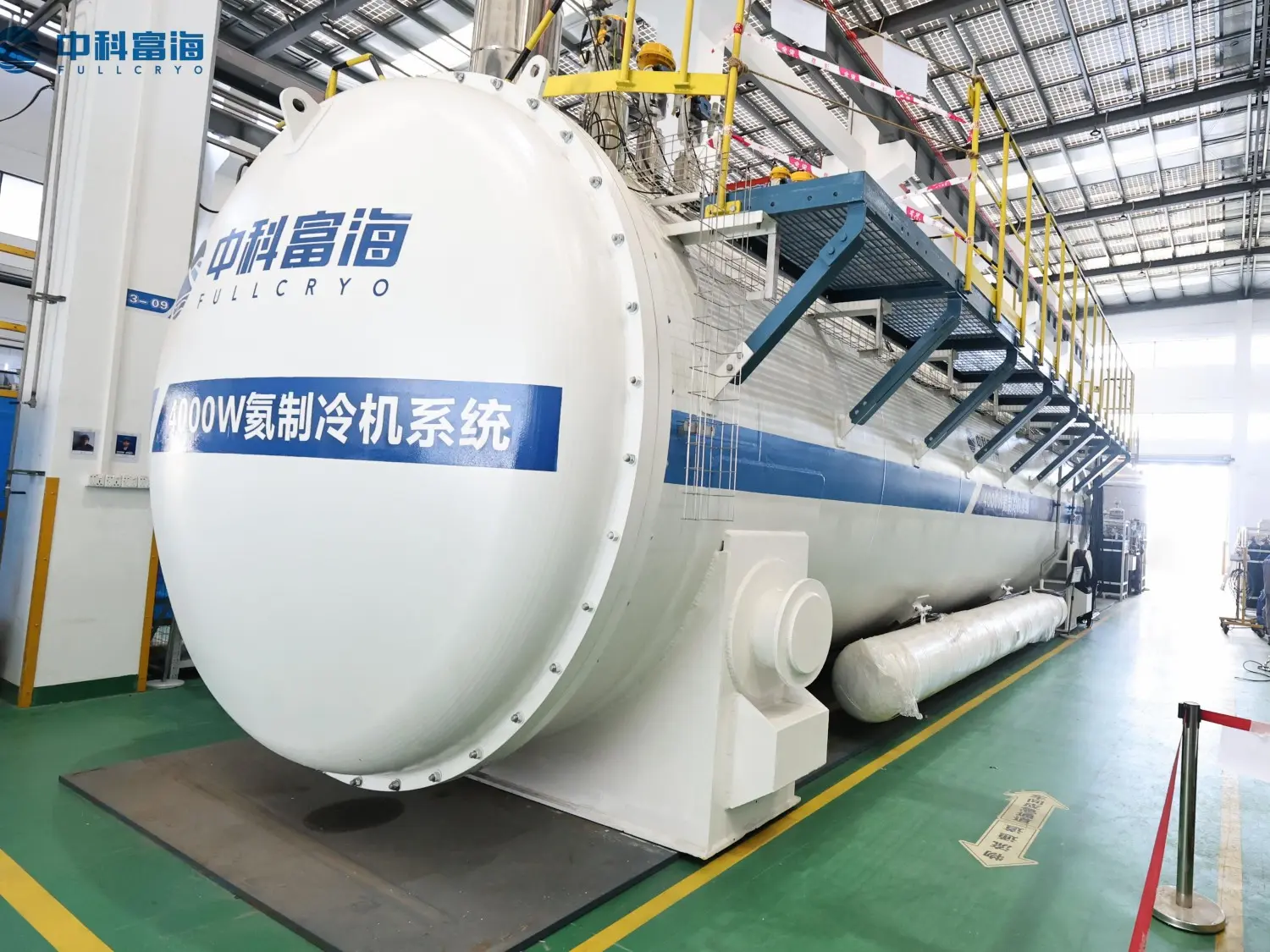

Factory Pictures