01

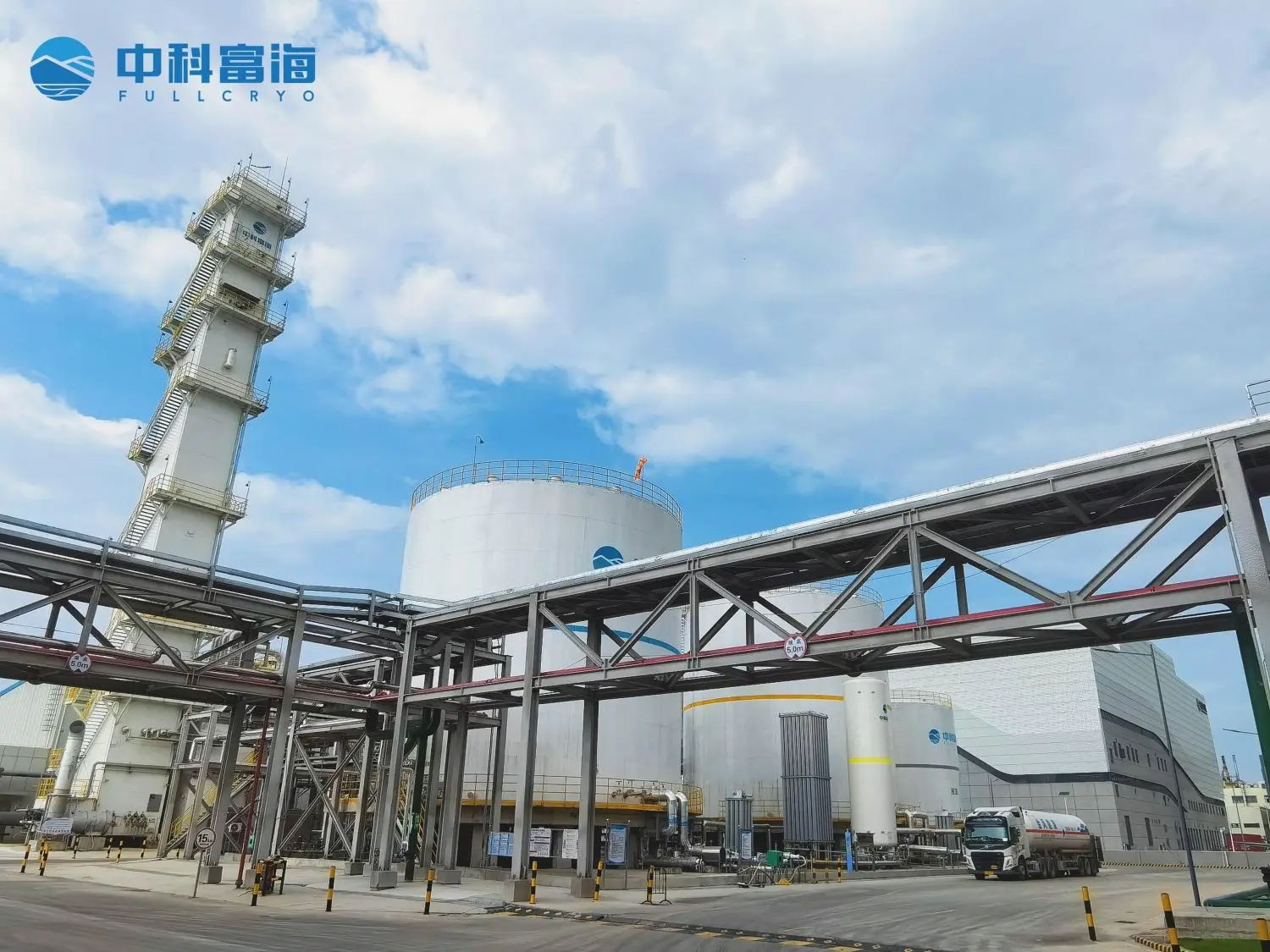

5000Nm3/H Oxygen Generating System Air Rectification Equipment

Product Description

Because the oxygen and nitrogen molecules in the air are evenly mixed, the separation of air in the gaseous state is very difficult.But liquid oxygen and liquid nitrogen, which make up liquid air, have different boiling points under the same pressure(At atmospheric pressure, oxygen has a boiling point -183 ℃ and nitrogen has a boiling point of -196℃ ).So we can first liquefy the air, and then gradually evaporate it, with the low-boiling components first evaporating into gases, and the high-boiling components remaining as liquids,operate repeatedly,then the oxygen concentration in the liquid goes up, the nitrogen concentration in the gas goes up,thus separating oxygen and nitrogen. This method of producing oxygen is called cryogenic oxygen production.

Operational Protocols:

1. Installation Requirements:

Site Preparation: Adequate space, ventilation, and structural support for the system.

Utilities: Reliable supply of electricity and, if applicable, backup power sources.

2. Training and Staffing:

Operator Training: Comprehensive training programs for staff on system operation, safety protocols, and emergency procedures.

Maintenance Personnel: Qualified technicians for routine maintenance and troubleshooting.

3. Monitoring and Control:

Automated Control Systems: Integration of control systems to monitor oxygen purity, flow rates, pressure, and system performance.

Alarm Systems: Alarms for critical parameters, such as low purity, high pressure, or system faults.

An oxygen generating system's contribution requirements are multifaceted, ensuring that the system operates efficiently, safely, and in compliance with relevant standards and regulations. These requirements include:

A.Technical specifications for capacity, purity, pressure, power, and environmental conditions.

B.Regulatory compliance with certifications and safety standards.

C.Operational protocols for installation, training, monitoring, and control.

D.Maintenance practices for routine and preventive maintenance.

E.Compliance and reporting mechanisms for regulatory and quality assurance.

F.Emergency preparedness plans and training for safety and incident management.

Adhering to these requirements ensures that the oxygen generating system provides a reliable and high-quality oxygen supply, crucial for both medical and industrial applications.

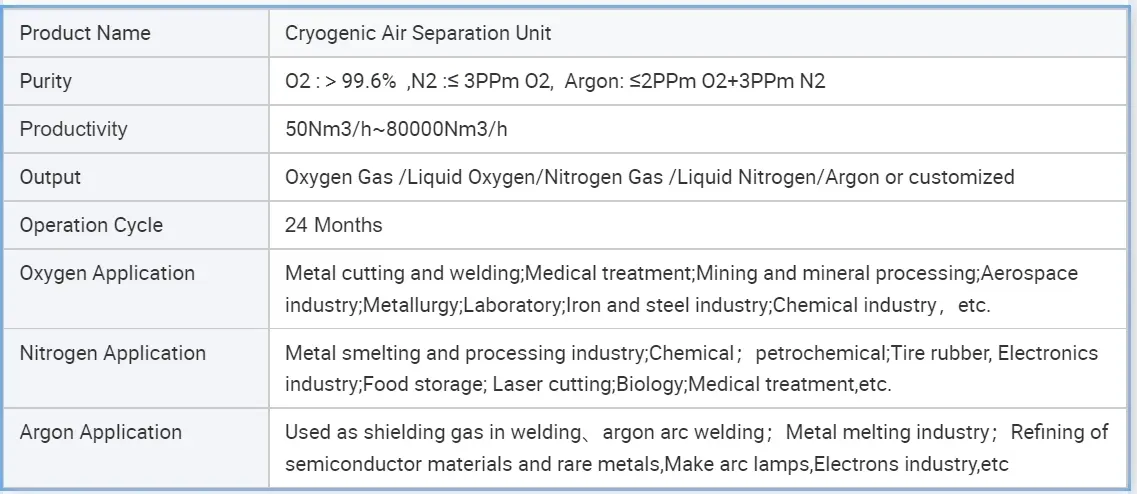

parameter

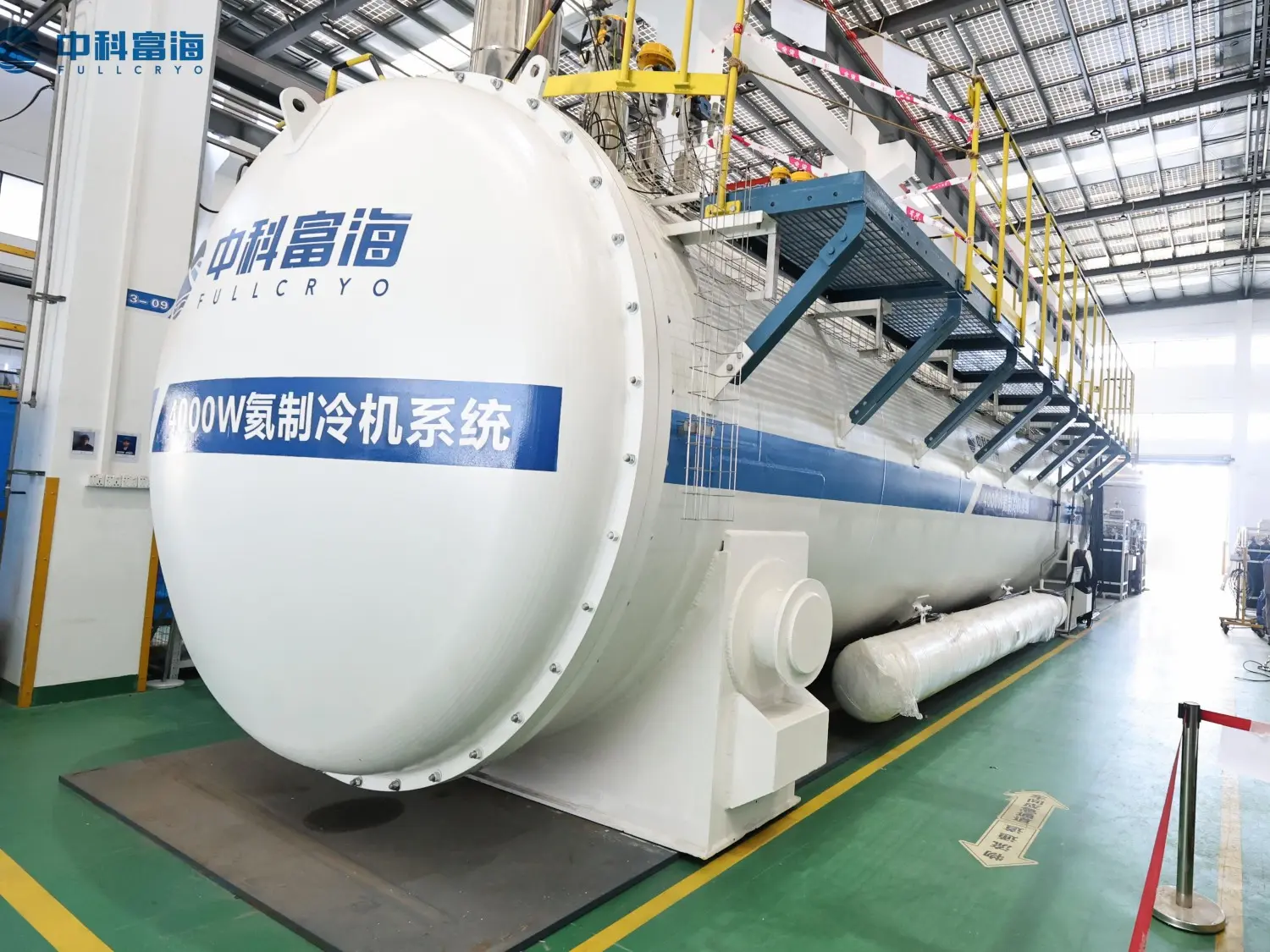

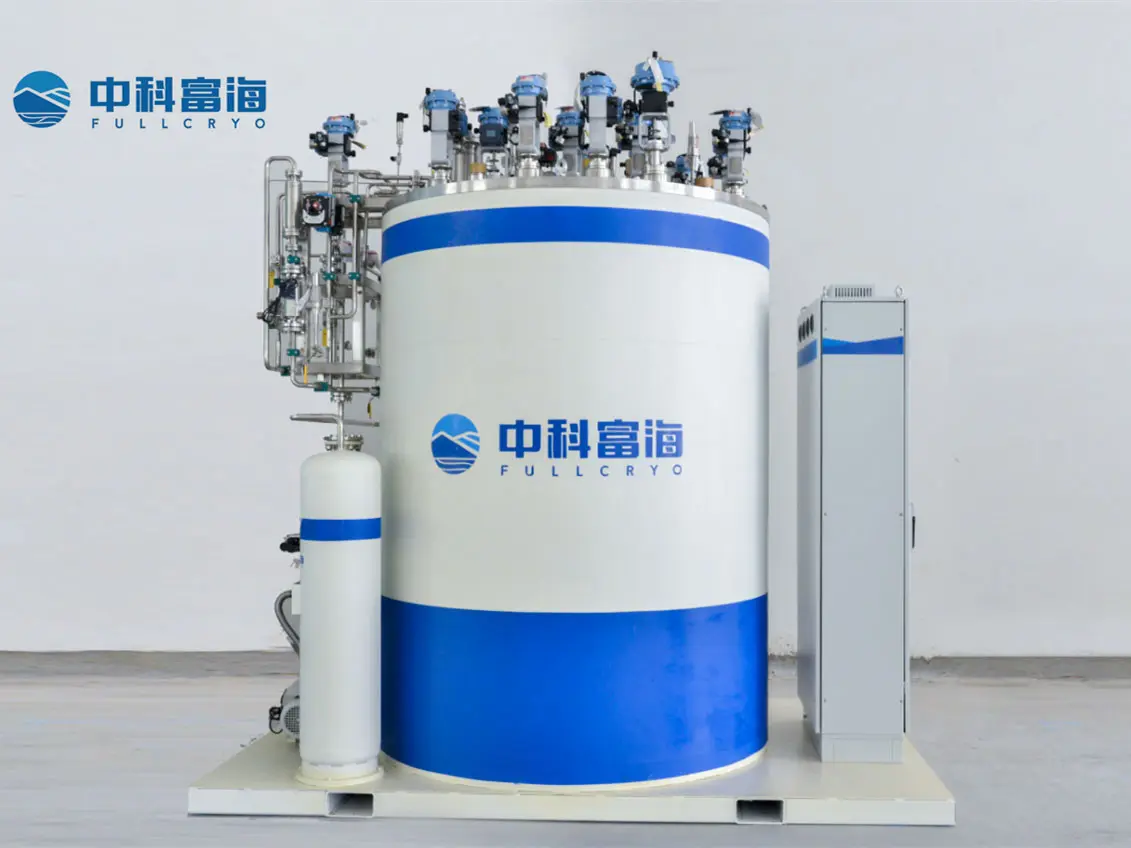

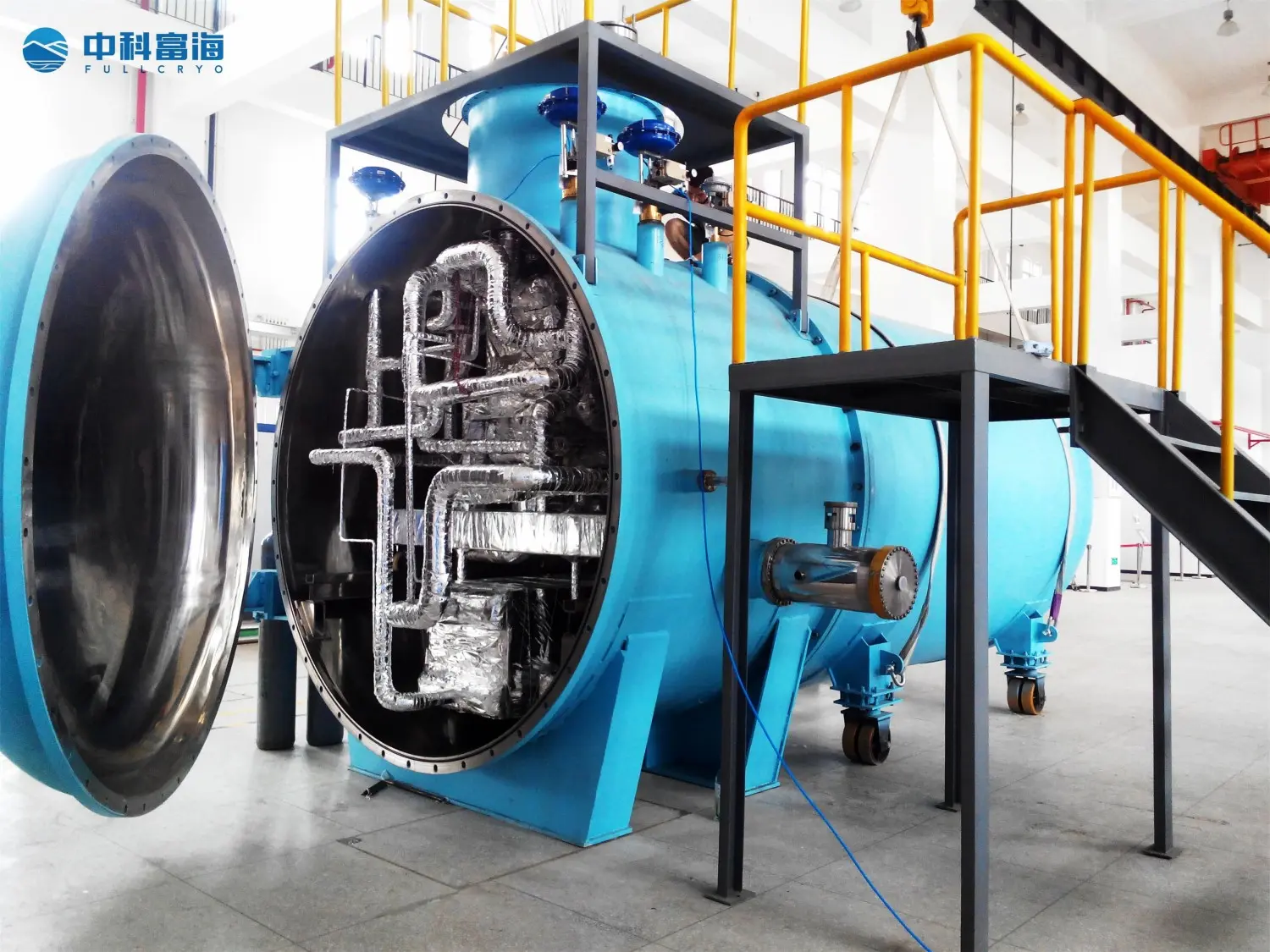

Factory Pictures