01

10000Nm3/h Oxygen And Nitrogen Making Plant

Product Description

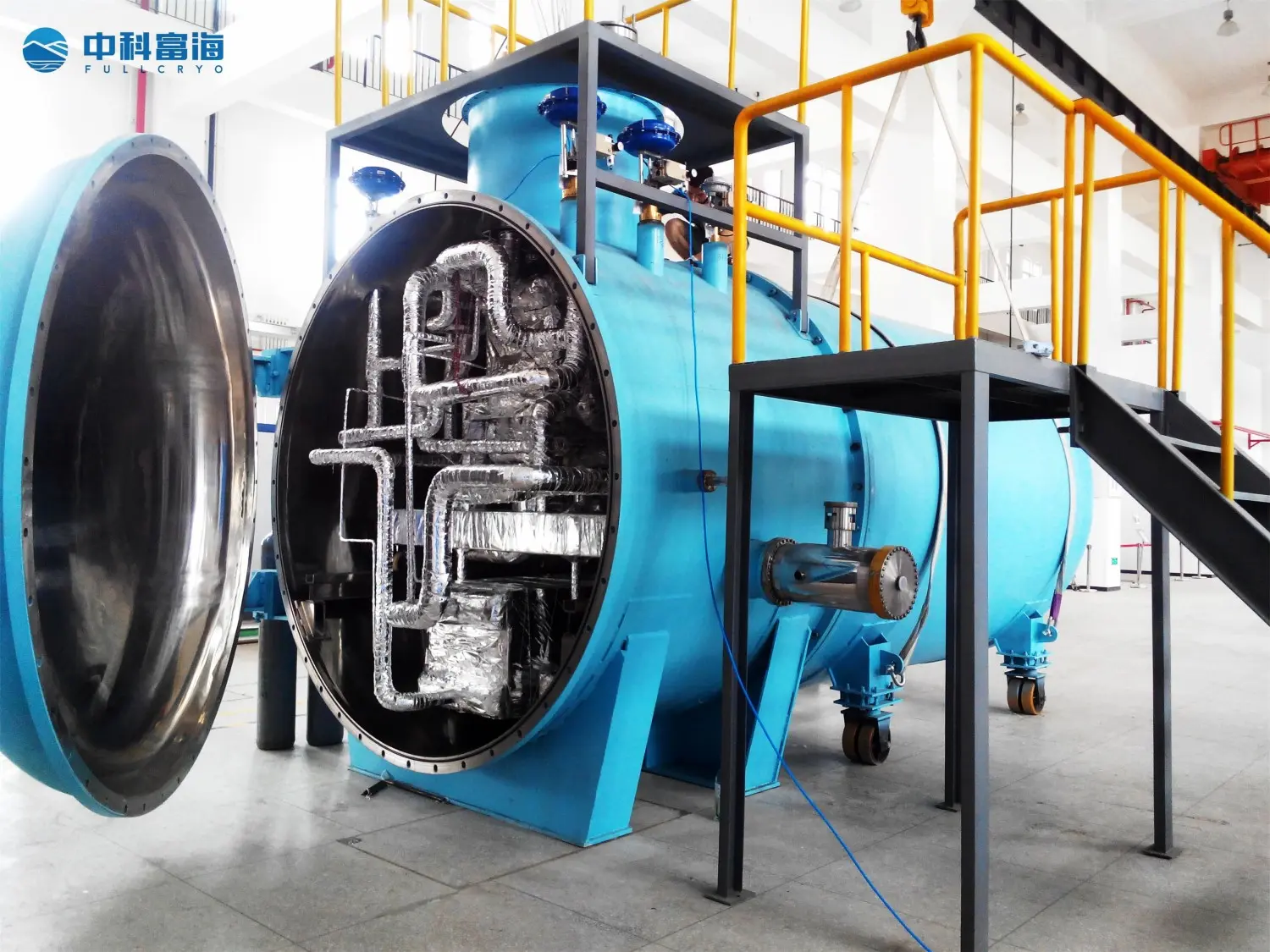

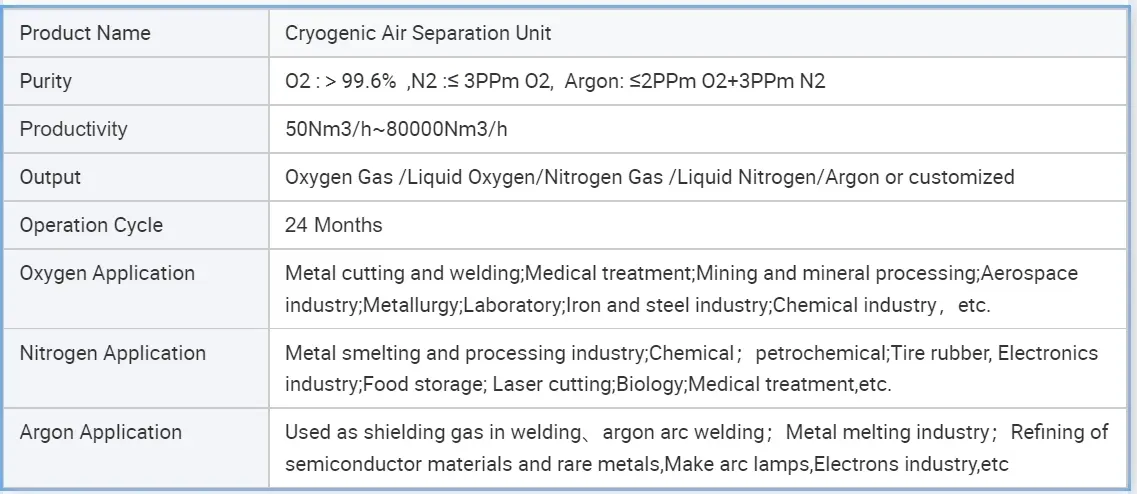

Oxygen and nitrogen manufacturing units are facilities that produce oxygen and nitrogen through an air separation process. Air separation involves separating air into its main components, namely nitrogen, oxygen and other trace gases. This is usually accomplished through a process called cryogenic distillation, which involves cooling the air to a very low temperature and then distilling it to separate the different components.

The oxygen and nitrogen produced by these plants have a wide range of industrial and medical applications. Oxygen is used in respiratory support in medical facilities, in industrial processes such as metal cutting and welding, and in the production of chemicals and fuels. Nitrogen is used in a variety of industrial applications, including as an inert gas for purging and blanketing, in food packaging to extend shelf life, and in the production of electronics and semiconductors.

We manufacture and export thoroughly automated oxygen plant and nitrogen plant for excessive purity oxygen and nitrogen manufacturing the usage of the trendy cryogenic air separation science for cylinder filling. It is additionally outfitted with a digital display panel that consistently assessments the oxygen purity and switches off when the purity drops. It additionally permits far flung diagnostic exams of the whole plant to see if the plant is working efficiently.Our gear is totally automatic, convenient to maintain, and produces a non-stop waft of oxygen immediately into the storage tank.

All of our professional technical team with extra than decade of experience can be engaged in gas design, exploration and development, and provides end users with technical support before, during and after sales, including complex design, drawings, schedules, key assignments, guidance for installation, training, and many others . Our The equipment conforms to international standards. Before the tools leaves the factory, we is going to conduct a comprehensive inspection and testing of each equipment, to make certain each equipment can meet the standard before leaving the stock.

parameter

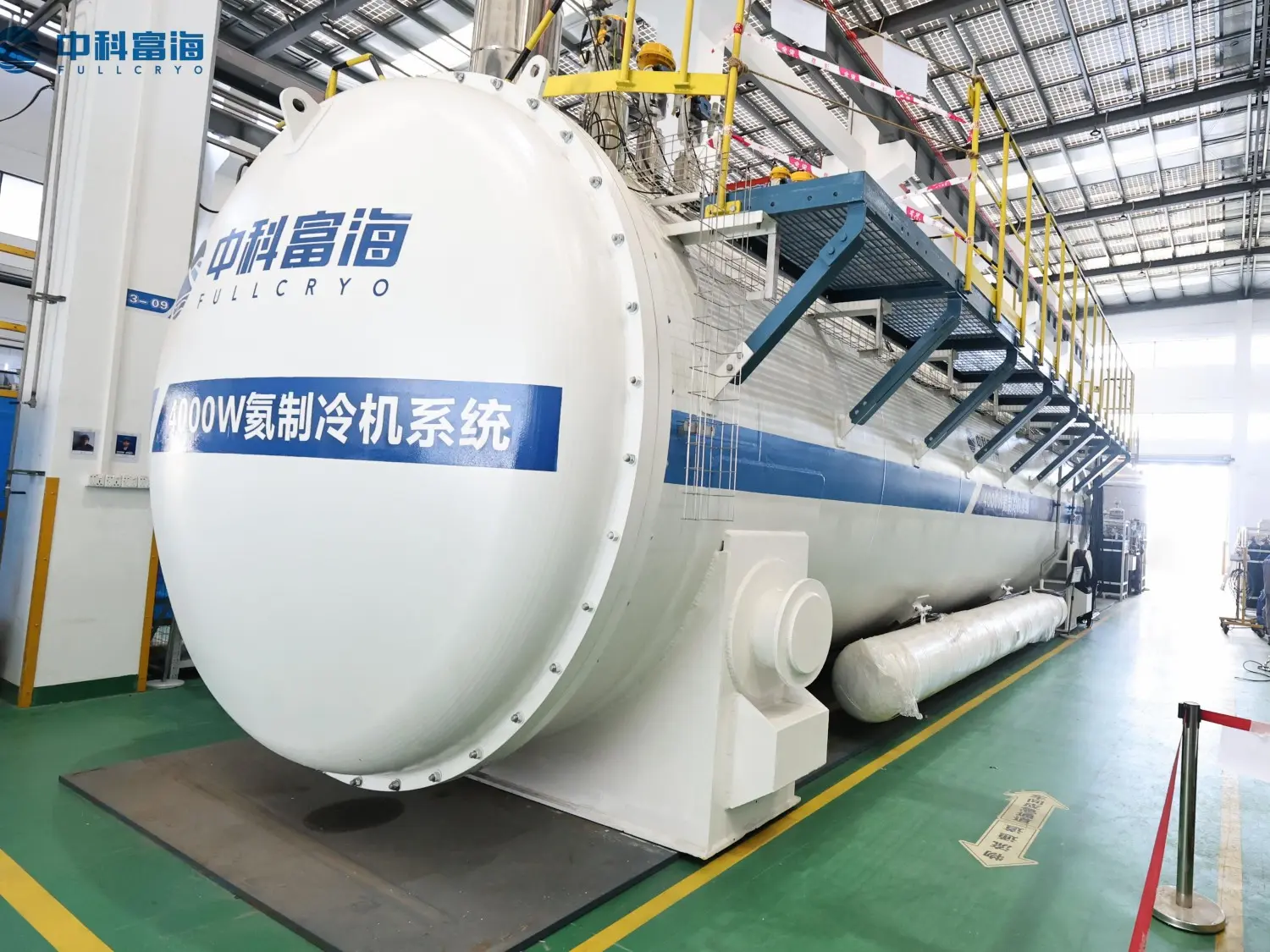

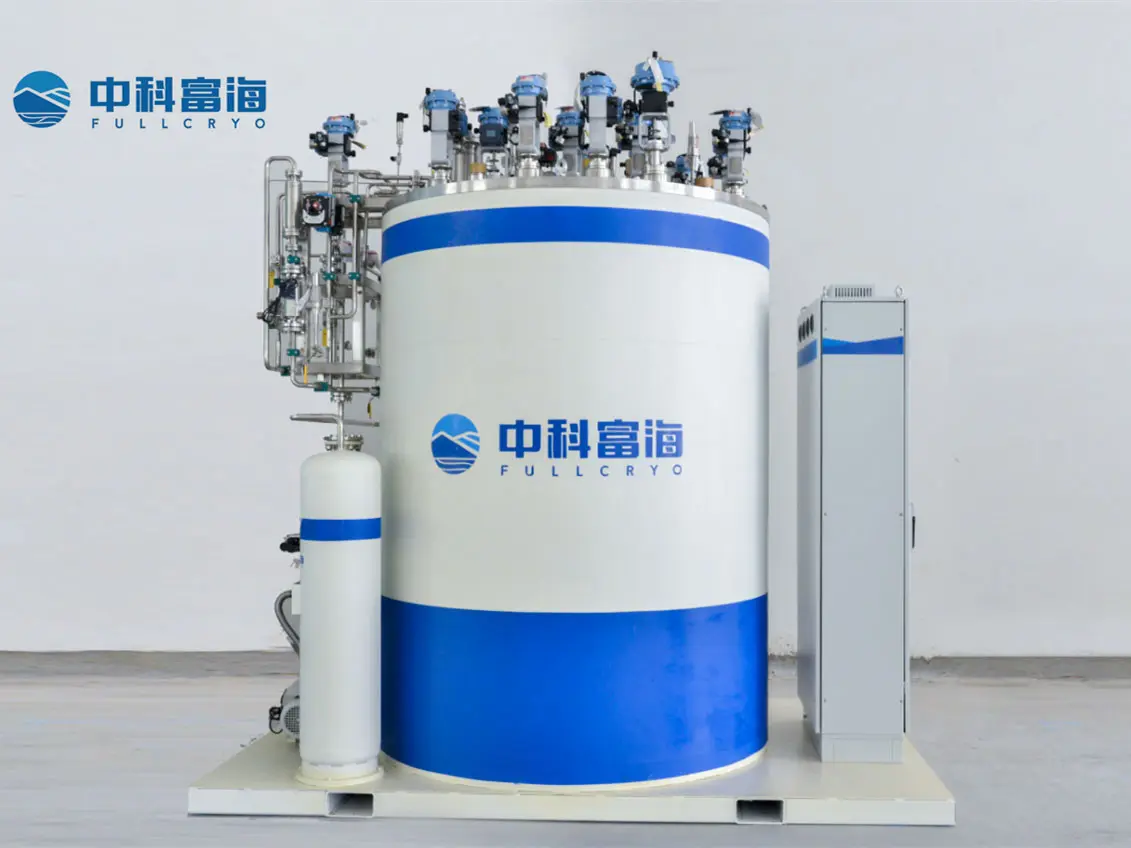

Factory Pictures