0102030405

100 L to 20,000 L Liquid Helium Dewar

Product Description

Features and Specifications:

1. Capacity:

Volume Range: 100 liters to 20,000 liters.

2. Construction Material:

Fullcryo liquid helium dewar is made of austenitic stainless steel and fully welded

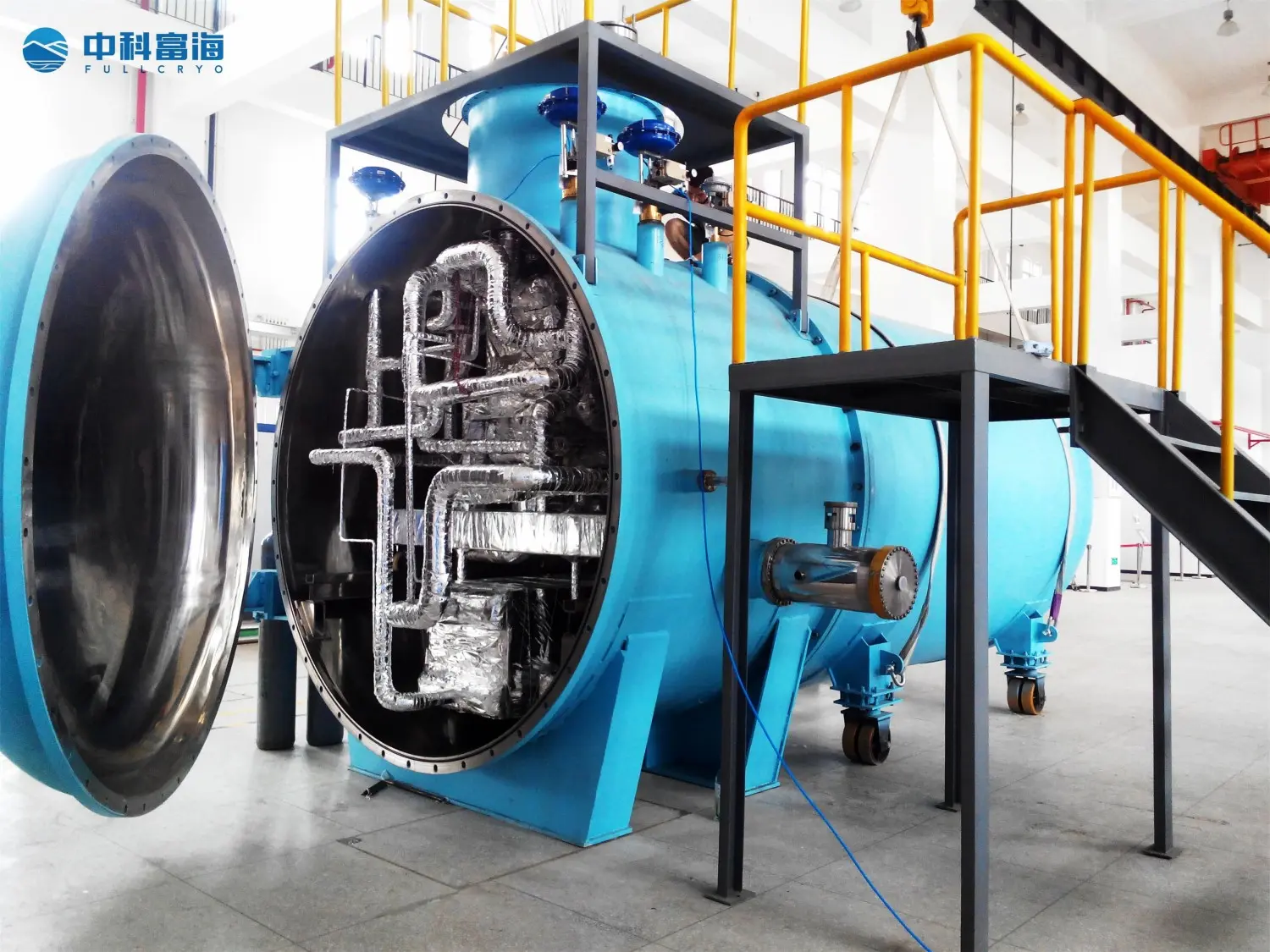

3. Insulation:

It is connected to the vacuumize equipment to vacuumize the interlayer. It can automatically open and release the pressure when the inner tank leaks, which plays a role of safety protection.

4. Pressure Rating:

Working Pressure:0.07Mpa

5. Temperature Control:

◆Sensors and Gauges: Monitor internal temperature to maintain cryogenic conditions.

◆Cryogenic Valves and Piping: Specifically designed to operate efficiently at extremely low temperatures.

6. Portability:

it has an integrated caster base and handrails for operation on all four sides, and is not limited by space;

7. Fittings and Connections:

◆Fill and Withdrawal Valves: Enable efficient loading and unloading of liquid helium.

◆Pressure Gauge: Allows for real-time monitoring of internal pressure.

◆Vent Valve: Safely releases excess pressure.

◆Safety Relief Devices: Ensure safe operation under various conditions.

Maintenance and Handling:

1. Regular Inspections:

Periodically check for signs of wear, damage, or leaks.

Ensure all safety devices and valves are operational.

2. Proper Handling:

Follow safety protocols during filling, transporting, and dispensing of liquid helium.

3. Training:

Ensure personnel are trained in the safe handling and maintenance of cryogenic dewars.

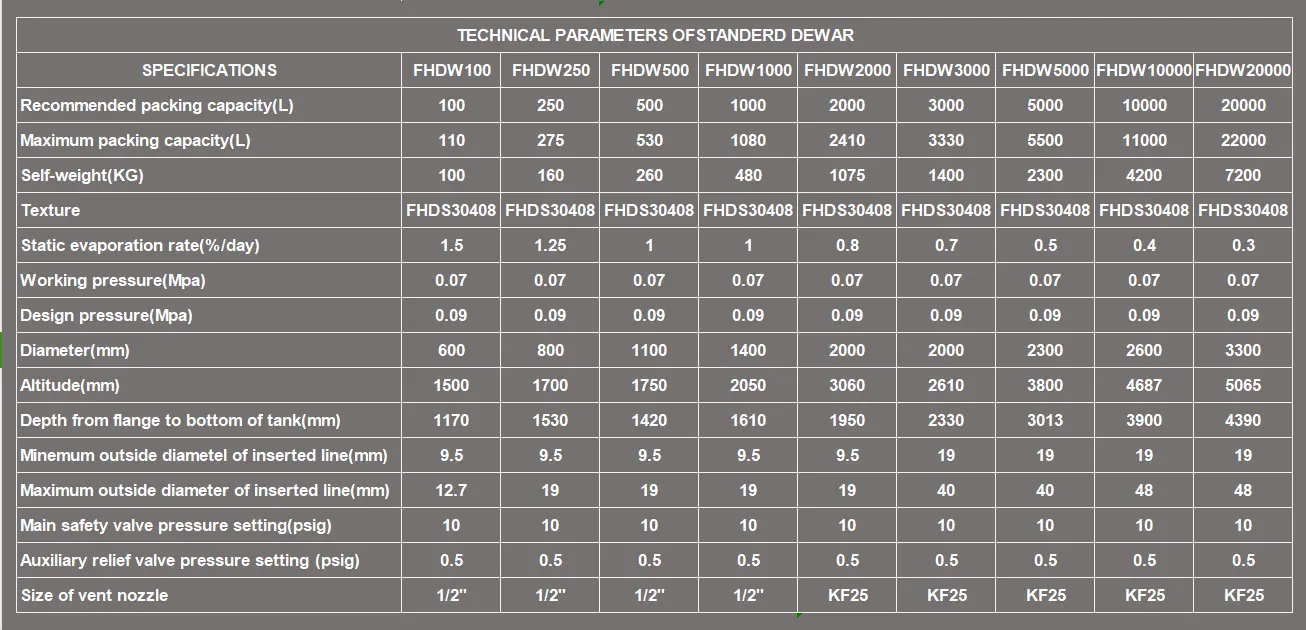

parameter

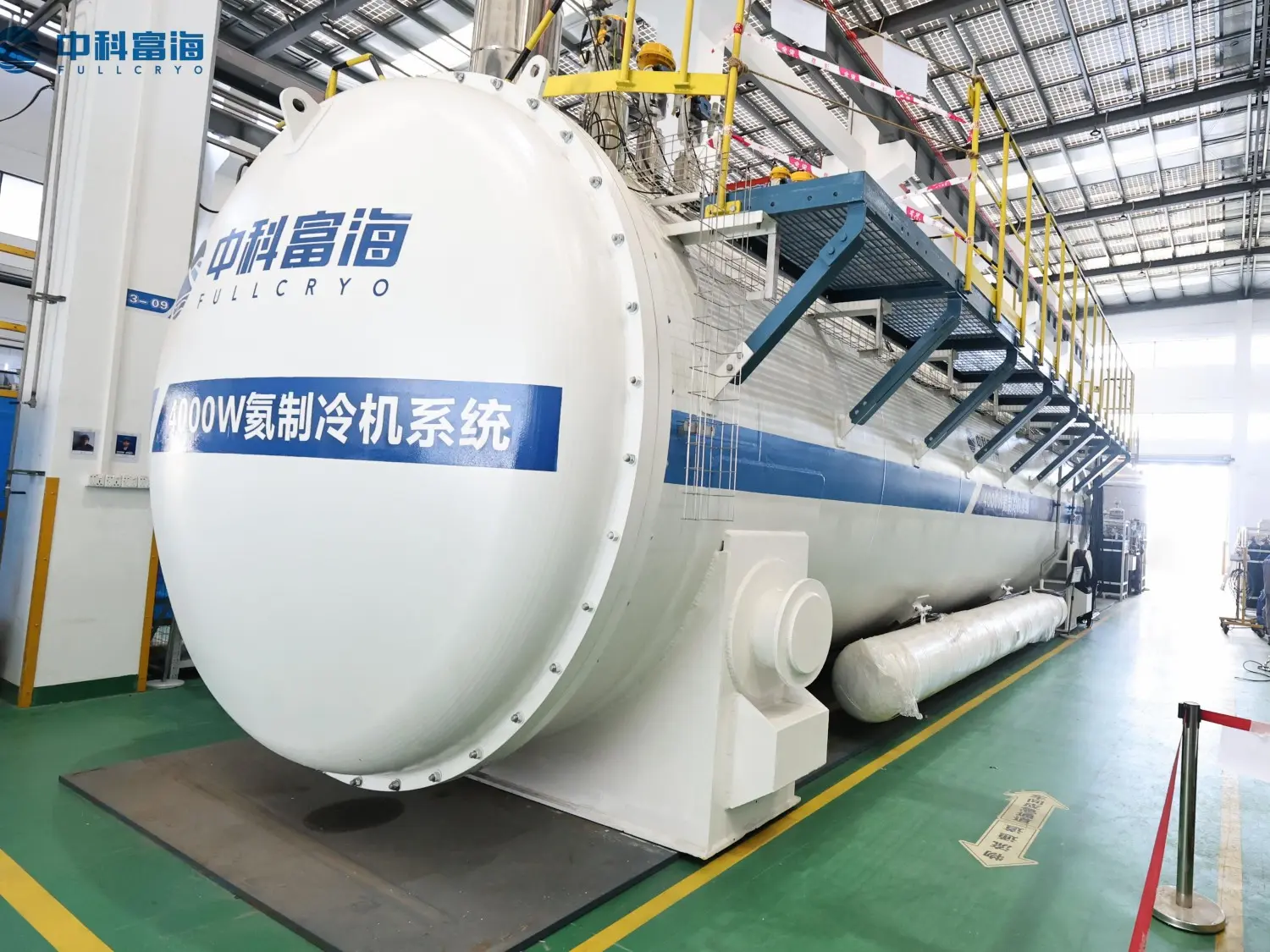

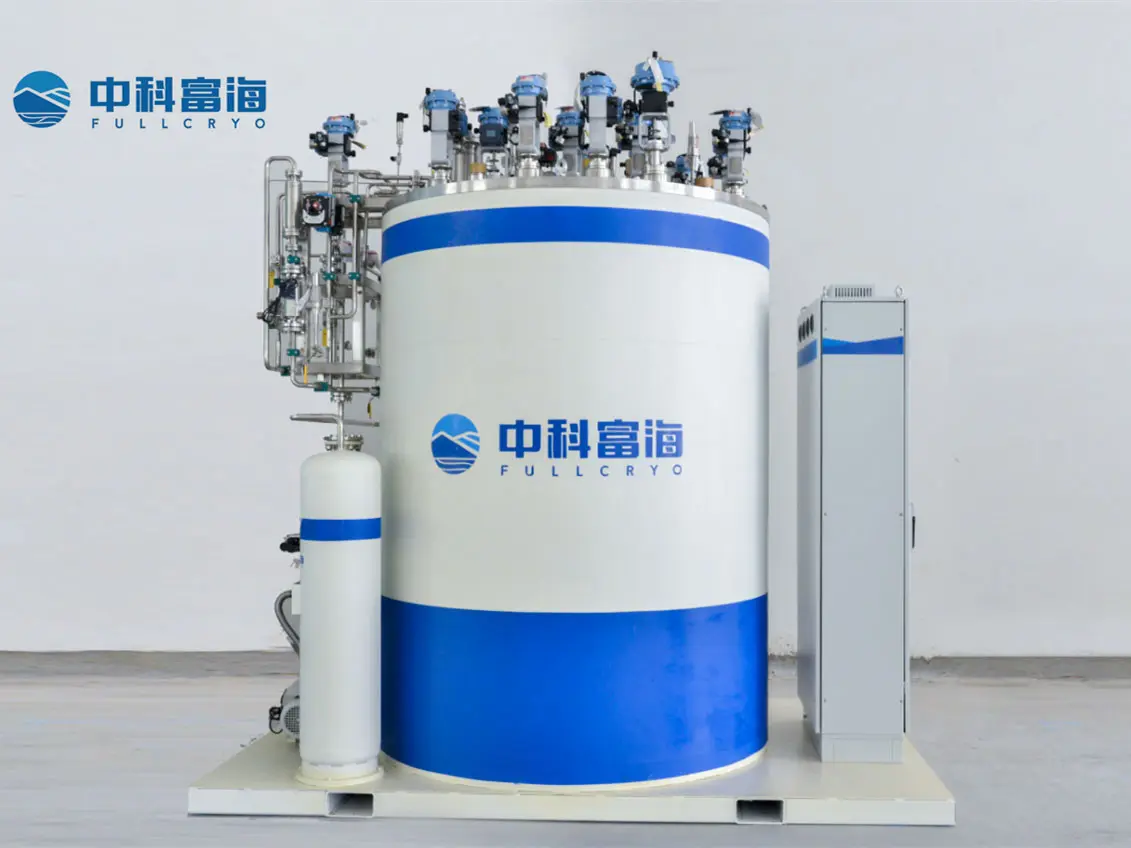

Factory Pictures