-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

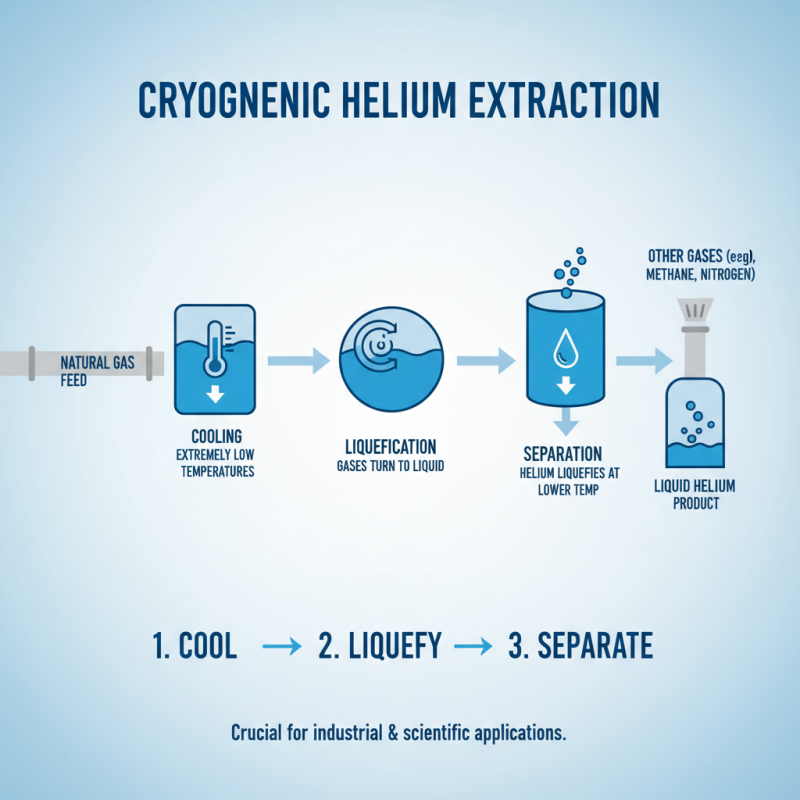

Extracting helium efficiently requires careful techniques. One crucial method is the Cryogenic Process Helium Extraction. This process leverages low temperatures to separate helium from other gases.

In the cryogenic environment, gases liquefy at specific temperatures. Helium, being the second lightest element, remains gaseous under these conditions. Understanding the balance of temperature and pressure is key. Each factor dramatically impacts the extraction efficiency.

Though effective, the method is complex. Operators must monitor systems closely to avoid losses. Equipment malfunctions during extraction can lead to significant helium waste. Achieving precision calls for skill, adjustment, and ongoing learning. Acknowledging these challenges is vital for improvement.

The extraction of helium is a crucial process in various industries. Helium is vital for many applications like MRI machines and space technology. Reports estimate that the global helium market is projected to reach $4.3 billion by 2027. Its importance in technology and medicine cannot be overstated. The increasing demand for helium underscores the necessity of efficient extraction methods.

Cryogenic processes are significant in helium extraction. This technique involves cooling gases to very low temperatures to separate helium from natural gas. The process can recover up to 99% of helium in some cases, highlighting its efficiency. However, there are challenges. The infrastructure required for cryogenic extraction is costly. Environmental concerns also arise from the energy-intensive process.

Moreover, not all extraction sites yield the same purity levels. Some reports indicate that helium purity can vary between 0.5% and 3% in different fields. This inconsistency can impact its applications. Furthermore, the global helium supply is finite. This scarcity forces industries to reevaluate their consumption habits. Sustainable practices in helium extraction are becoming more urgent.

The cryogenic process plays a vital role in extracting helium from natural gas. This method involves cooling gas to extremely low temperatures. The objective is to liquefy gases. Helium is separated as it requires lower temperatures compared to other gases.

During the process, a series of compressions and expansions occur. This changes the temperature and pressure, allowing for the separation of helium. Specific techniques like Joule-Thomson cooling are commonly applied. The effectiveness of the process can vary based on the initial gas composition.

Challenges may arise in managing energy efficiency, as cooling requires significant power. Equipment must be maintained properly; otherwise, efficiency diminishes. There can also be inconsistent helium concentrations in different gas sources, complicating extraction. Each step needs careful evaluation to enhance yield and reduce waste.

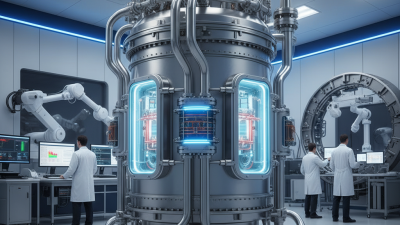

The cryogenic process for helium extraction relies on specialized equipment and cutting-edge technologies. Key components include cryogenic distillation units and liquefaction systems. These units operate at extremely low temperatures, often below -269°C, to separate helium from other gases. Advanced cryogenic pumps and compressors play a vital role in maintaining these temperatures and ensuring efficient gas flow.

In a recent industry report, it was noted that the global helium market is projected to grow at a rate of 15% annually. This growth fuels demand for more efficient extraction methods. The optimization of existing technologies is crucial for reducing costs while maximizing yield. Many facilities are now upgrading their systems to incorporate more efficient designs.

Tips for effective cryogenic helium extraction include regular maintenance of cooling systems and monitoring gas purity levels. Monitoring ensures the extraction remains efficient. Operators should keep an eye on potential issues like frost build-up, which can disrupt processes. Investing in backup systems is also recommended. This adds redundancy and minimizes downtime during unexpected failures.

Helium extraction through cryogenic processes requires careful measurement of yield and purity. Efficiency metrics play a critical role in determining how effectively helium can be recovered. The yield defines the amount of helium extracted versus the amount available, while purity indicates how much of the final product is, in fact, helium. High purity is essential for many applications, especially in scientific fields.

A primary aspect to consider is the cooling temperature. Cryogenic temperatures can significantly impact yield. For instance, slight fluctuations can lead to inconsistent results. Monitoring and adjusting these temperatures is crucial for optimizing the extraction process.

Tips: Regularly calibrate your temperature sensors. This ensures accurate readings, minimizing errors. Also, examine your filtration systems for any potential leaks.

Consider the pressure levels in your extraction chamber. Pressure changes can affect both yield and purity. With insufficient pressure, you may lose helium during the process. On the other hand, excessive pressure might lead to impurities in the collected gas.

Tips: Implement a routine check on pressure gauges. Float switches may also help monitor pressure levels effectively. Aim for a balance that maximizes recovery while retaining purity.

In helium production, safety protocols are crucial. The cryogenic process can pose risks, including high-pressure equipment and low temperatures. Workers must wear protective gear to prevent frostbite. Regular maintenance checks on equipment help avoid leaks. Training for personnel is essential to ensure safety standards.

Environmental impacts should be evaluated carefully. Helium extraction can affect local ecosystems. Water usage in cooling systems needs attention. It's vital to monitor any potential emissions during the cryogenic process. Companies should strive for sustainable practices, reducing negative effects on the environment.

Additionally, community awareness is often overlooked. Engaging with local residents about helium extraction can foster trust. Sharing information about safety measures and environmental impacts promotes transparency. A well-informed community can better understand the industry’s operations and concerns.

Balancing production needs with environmental responsibility requires ongoing reflection.