-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

The efficient extraction of helium from boil-off gas is becoming increasingly crucial as the demand for this finite resource continues to rise. Boil-off gas helium extraction not only maximizes recovery rates but also significantly enhances the sustainability of helium usage in various industries. As helium plays a fundamental role in areas such as medical imaging, scientific research, and various technological applications, advancing extraction techniques is vital for ensuring a steady supply.

In this context, understanding the processes and technologies that govern boil-off gas helium extraction can lead to improved operational efficiencies and reduced waste. By adopting innovative methods to capture and purify helium from boil-off gas, companies can optimize their operations while contributing to responsible resource management. This introduction sets the stage for exploring the fundamental principles, current advancements, and best practices in helium extraction techniques, aiming at maximizing recovery from this essential gas source. Through this exploration, we can not only enhance the profitability of helium operations but also promote a more sustainable approach to its utilization.

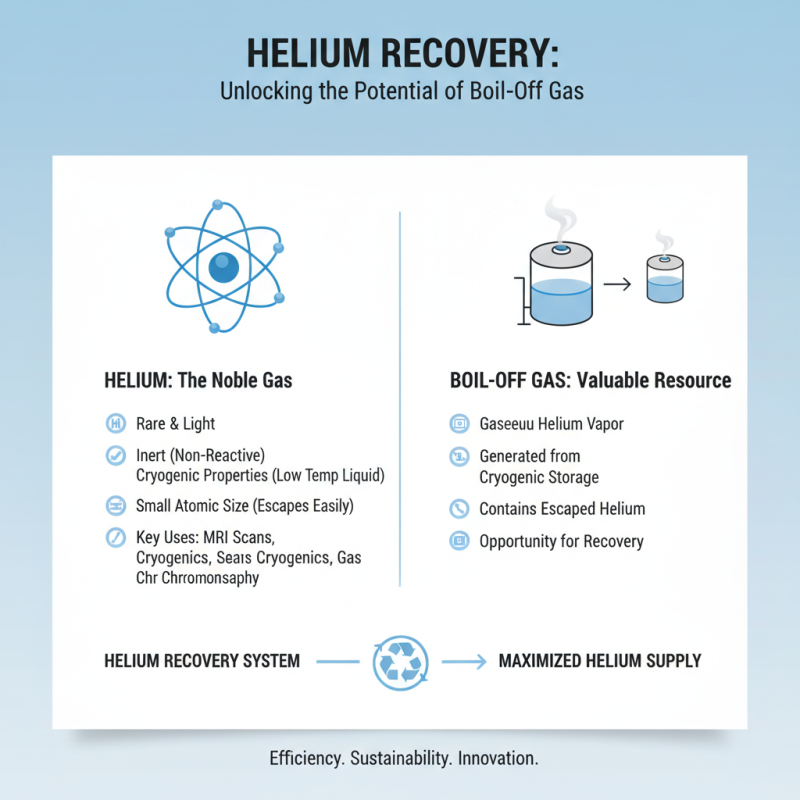

Helium is a rare noble gas with unique properties that make it invaluable in various industrial applications, including cryogenics, gas chromatography, and even in medical applications for MRI scans. Its lightness and inertness allow it to remain in a gaseous state under low temperatures, but it also has a tendency to escape due to its small atomic size. Boil-off gas, which consists of helium vapor generated from cryogenic storage, presents both a challenge and an opportunity for helium recovery. Understanding the properties of both helium and boil-off gas is essential for developing effective extraction methods to maximize helium recovery.

When dealing with boil-off gas, one key aspect to consider is its temperature and pressure conditions. The volatility of helium means that maintaining optimal conditions during storage and extraction is crucial for minimizing losses. This can be achieved by employing insulation and using efficient pumps designed specifically for low temperatures.

Tips: Consider implementing a closed-loop system for capturing boil-off gas. This reduces atmospheric losses and ensures higher recovery rates. Additionally, regularly monitoring gas composition can help adjust extraction processes in real-time, improving efficiency and maximizing helium recovery from the boil-off gas.

Efficiently collecting boil-off gas is key to maximizing helium recovery, especially in environments where helium is in high demand. One effective technique involves the implementation of advanced cryogenic storage systems that minimize gas evaporation. By maintaining ultra-low temperatures, these systems reduce the amount of gas that boils off, allowing for more effective capture and storage. Regular monitoring and maintenance of these systems ensure optimal performance, directly impacting the overall recovery rate.

Moreover, integrating a gas collection manifold can streamline the process. This setup allows for the centralized collection of boil-off gas, which can then be redirected into a recovery unit. Utilizing multi-phase flow meters can enhance the precision of gas measurement, ensuring that no valuable helium escapes during the collection phase. Additionally, deploying insulation materials around storage tanks can significantly decrease heat transfer, further reducing boil-off rates and allowing for enhanced recovery efficiency. Implementing these techniques not only optimizes the helium extraction process but also promotes sustainability within the helium supply chain.

The separation of helium from other gases in boil-off gas is critical for maximizing recovery during helium extraction processes. One effective method involves cryogenic distillation, where the gas mixture is cooled to extremely low temperatures. At these temperatures, helium, which has a lower boiling point compared to other gases, can be liquefied and separated efficiently. This method is particularly advantageous due to its ability to handle large volumes of gas, producing high purity helium suitable for various industrial applications.

Another approach for separating helium is pressure swing adsorption (PSA). This technique uses adsorbent materials that preferentially bind different gas molecules under pressure. When the pressure is reduced, the adsorbed gases are released, allowing for helium to be collected. PSA systems can be designed for specific gas compositions, making them versatile in different operational environments. This combination of cryogenic distillation and PSA is pivotal in enhancing recovery rates, ensuring that valuable helium is extracted effectively from boil-off gas while minimizing waste and operational costs.

Efficient helium recovery from boil-off gas is crucial for maximizing extraction yields in a sector marked by increasing demand and finite supply. According to a report by the U.S. Geological Survey, helium production has been under significant pressure, with global reserves declining at an alarming rate of approximately 1.7% per year. This places additional importance on optimizing recovery processes to ensure that we capitalize on every opportunity to reclaim this valuable resource.

One effective method involves implementing advanced cryogenic distillation techniques, which have been shown to enhance helium recovery rates by up to 90%. By carefully controlling temperature and pressure during the distillation process, operators can reduce the loss of helium during the boil-off phase. Additionally, utilizing online monitoring systems to track the concentration of helium within the boil-off gas can lead to more informed decisions about when to initiate extraction processes, further improving efficiency.

**Tips for optimizing helium recovery:**

- Invest in automated monitoring systems to maintain optimal temperature and pressure settings throughout the extraction process. This can significantly reduce waste and increase recovery efficiency.

- Regularly train staff on the latest recovery techniques and equipment, as human error can lead to substantial losses in helium yield.

- Collaborate with industry experts to conduct periodic reviews of your recovery processes and identify areas for improvement. Continuous optimization is critical in today’s competitive market.

| Process Stage | Technique | Efficiency (%) | Recovery Rate (L/min) | Cost ($/L) |

|---|---|---|---|---|

| Cryogenic Condensation | Liquid Nitrogen Cooling | 85 | 12 | 0.15 |

| Membrane Separation | Polymeric Membranes | 80 | 10 | 0.20 |

| Pressure Swing Adsorption | Activated Carbon | 90 | 15 | 0.10 |

| Cryo-Adsorption | Zeolite Adsorbents | 75 | 8 | 0.25 |

| Distillation | Cryogenic Distillation | 88 | 14 | 0.18 |

When extracting helium from boil-off gas, safety is of paramount importance. The process typically involves handling cryogenic temperatures, which can pose serious risks such as frostbite or even asphyxiation due to the displacement of oxygen in the air. Workers involved should be well-trained in safety protocols and equipped with appropriate personal protective equipment (PPE) to mitigate these risks. It’s crucial to have proper ventilation in extraction areas to ensure that any potential leaks do not lead to a hazardous environment.

Tips for ensuring safety during helium extraction include conducting regular safety drills and ensuring all equipment is maintained and inspected frequently. Always establish a clear protocol for emergency situations, including immediate evacuation procedures. Furthermore, it is beneficial to employ gas detection systems that can alert workers to the presence of helium or reduced oxygen levels, enabling quick action to prevent accidents.

In addition to personal safety measures, proper storage and handling of extracted helium are vital. Helium should be stored in specially designed containers to prevent leaks and ensure stability. Regular monitoring of pressure levels can help in early detection of any potential issues, which can lead to safer operations overall. Prioritizing safety not only protects personnel but also enhances the efficiency of the helium extraction process.