-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

A Cryogenic Semi Trailer is a specialized transport vehicle designed to carry cryogenic liquids at extremely low temperatures. These trailers play a crucial role in various industries, including energy, aerospace, and food services, where the preservation and transportation of materials at sub-zero temperatures are essential. By understanding the construction and functionality of these trailers, we can appreciate their significance in modern logistics and supply chain management.

The operation of a Cryogenic Semi Trailer relies on advanced insulation materials and state-of-the-art engineering techniques to maintain the integrity of the cryogenic contents during transport. These trailers are equipped with specialized valves and pumps that facilitate safe loading and unloading of gases such as liquid nitrogen, oxygen, and argon. As industries continue to explore the benefits of cryogenic technologies, the demand for efficient and reliable transportation solutions like the Cryogenic Semi Trailer is likely to grow, underscoring the importance of this innovative transport method in facilitating various processes across multiple sectors.

A cryogenic semi-trailer is a specialized type of trailer designed to transport liquefied gases at extremely low temperatures. These gases include liquid nitrogen, helium, and oxygen, which require precise handling and insulation to maintain their liquefied state during transit. The design of a cryogenic semi-trailer involves advanced thermal insulation materials and a vacuum-sealed container, minimizing heat transfer from the environment and ensuring that the cargo remains stable and safe.

The operation of a cryogenic semi-trailer hinges on its ability to maintain low temperatures through advanced refrigeration technology. Equipped with cryogenic pumps and pressurization systems, these trailers allow for controlled loading and unloading of cryogenic liquids. An integral part of the system is the pressure relief valves, which prevent excessive pressure buildup caused by heat ingress. Overall, these sophisticated trailers are essential for industries requiring the transport of cryogenic fluids, supporting sectors such as medical, aerospace, and energy with reliable and efficient logistics solutions.

This bar chart illustrates the temperature distribution of various cryogenic liquids commonly transported using cryogenic semi trailers. The temperatures are measured in Kelvin, reflecting the extreme cold necessary for these materials to remain in liquid form.

Cryogenic semi trailers are essential in the transport of liquefied gases such as LNG, oxygen, and nitrogen. Their design revolves around several key components that ensure the safe and efficient movement of these ultra-cold materials. The insulated tank is perhaps the most critical part, usually constructed from materials capable of withstanding extreme temperatures. According to industry reports, such as those from the Cryogenic Society of America, the insulation typically achieves a thermal resistance rating of R-30 or higher, minimizing heat transfer and maintaining cryogenic conditions during transit.

Another vital component is the vaporizer, which transforms the stored liquid back into gas for use at the destination. This process relies heavily on efficient heat exchange, and modern vaporizers can boast efficiencies of up to 99%. Furthermore, advanced safety features, including pressure relief systems and robust monitoring equipment, are paramount. Data indicates that implementing these safety mechanisms can lead to a significant reduction in accident rates, making cryogenic transportation safer than ever.

**Tips:** When working with cryogenic semi trailers, ensure regular maintenance checks are performed on the insulation and pressure relief valves. Additionally, training staff on emergency response procedures can mitigate risks associated with handling cryogenic materials.

Cryogenic semi trailers are specialized transport vehicles designed to carry liquefied gases at extremely low temperatures. These trailers are essential for industries that require the transportation of materials such as liquid nitrogen, oxygen, and argon, which are often used in medical, aerospace, and industrial applications. The insulation systems in cryogenic semi trailers are built to minimize heat transfer, typically utilizing materials with high thermal resistance such as vacuum insulation or multilayer insulation. This advanced technology helps maintain the boiling points of the transported substances, preventing gasification and ensuring they remain in their liquid state.

To maintain the low temperatures necessary for transporting cryogenic materials, these trailers are equipped with specialized refrigeration systems. According to industry reports, cryogenic trailers can maintain temperatures as low as -196°C (-321°F), which is critical for the safe and efficient transport of liquefied gases. Furthermore, the design of these trailers often includes pressure relief valves and safety devices that manage the pressure changes during transit, adhering to strict regulations and ensuring safe operation. The effectiveness of cryogenic semi trailers in maintaining low temperatures not only enhances the efficiency of transport logistics but also significantly reduces the risk of accidents associated with the handling of volatile substances.

| Feature | Description |

|---|---|

| Purpose | Transporting cryogenic liquids such as LNG (Liquefied Natural Gas), LPG (Liquefied Petroleum Gas), and liquid nitrogen. |

| Insulation Type | Multi-layer insulated vacuum chamber to minimize heat transfer. |

| Temperature Range | Can maintain temperatures as low as -196 °C (-321 °F). |

| Material | Constructed from durable alloys and composites designed to withstand extreme conditions. |

| Safety Features | Pressure relief valves, temperature monitoring systems, and emergency shut-off controls. |

| Loading/Unloading Mechanism | Specialized pumps and fittings to facilitate safe loading and unloading of cryogenic liquids. |

| Applications | Used in natural gas distribution, industrial gas supply, and scientific research. |

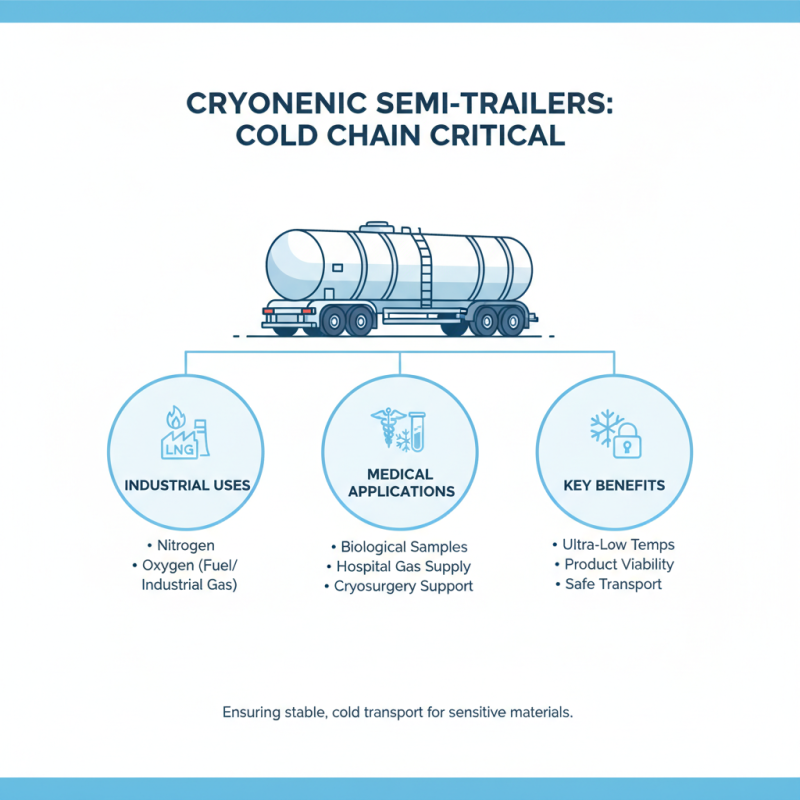

Cryogenic semi trailers play a crucial role in several industries that require the transport of liquefied gases at extremely low temperatures, such as nitrogen, oxygen, and LNG (liquefied natural gas). In the medical field, these trailers are essential for transporting cryogenic fluids that are vital for various applications, including the preservation of biological samples and the supply of medical gases for hospitals. Their ability to maintain stable, low temperatures ensures that these sensitive materials remain viable during transit.

Moreover, the food and beverage industry also benefits from cryogenic semi trailers, particularly in the transportation of frozen products and gases used in food processing. The rapid freezing capabilities allow for the preservation of food quality and safety while extending shelf life. Additionally, industries involved in semiconductor manufacturing rely on cryogenic transport for the delivery of gases necessary for the production of microchips. The versatility and efficiency of cryogenic semi trailers make them indispensable in these sectors, highlighting their significance in modern supply chains.

Operating cryogenic semi trailers involves meticulous safety measures due to the extreme temperatures and potential hazards associated with transporting liquefied gases. First and foremost, operators must ensure that all personnel are adequately trained in handling cryogenic materials. This includes an understanding of the properties of the gases being transported, the risks of gas leakage, and emergency response procedures in case of an accident.

Additionally, regular maintenance and inspections of the semi trailers are crucial. This involves checking the integrity of the insulation and ensuring that cryogenic valves and pressure relief systems are functioning correctly. Operators should also equip the trailers with appropriate personal protective equipment, such as cryogenic gloves and face shields, to protect against accidental spills and exposure. By adhering to these safety protocols, the risks associated with operating cryogenic semi trailers can be significantly minimized, ensuring both the safety of the personnel and the integrity of the cargo.