-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

The global demand for energy-efficient solutions has never been more pressing, as industries strive to reduce greenhouse gas emissions while maintaining operational efficiency. One innovative response to these challenges is the adoption of Cryogenic Refrigeration Systems, which operate at extremely low temperatures to improve energy efficiency. According to a report by the International Institute of Refrigeration, optimizing refrigeration systems can yield energy savings of up to 30%, significantly decreasing operational costs and minimizing environmental impact. As industries such as food processing, pharmaceuticals, and cryogenics increasingly turn to these advanced technologies, the significance of Cryogenic Refrigeration Systems in enhancing energy efficiency is becoming clear. This technological evolution not only supports sustainability goals but also opens the door to new opportunities in energy management, making it a key player in the future of industrial refrigeration strategies.

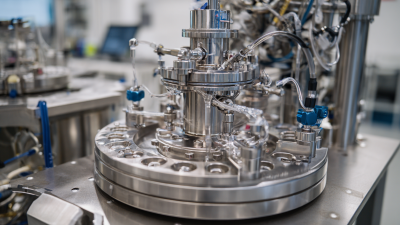

Cryogenic refrigeration systems operate at extremely low temperatures, typically below -150 degrees Celsius, utilizing advanced technology to achieve remarkable energy efficiency. According to a report by the International Institute of Refrigeration, these systems can improve energy efficiency by up to 60% compared to conventional refrigeration systems. This significant reduction in energy consumption not only lowers operational costs but also minimizes environmental impact, making cryogenic solutions an attractive option across various industries, including aerospace, healthcare, and food processing.

At the core of cryogenic systems is the use of cryogens, such as liquid nitrogen or helium, which absorb heat efficiently at low temperatures. This process allows for enhanced cooling capabilities, which are crucial for preserving sensitive materials and extending product shelf life. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers revealed that implementing cryogenic technology can reduce greenhouse gas emissions by as much as 30%, supporting the push for sustainable practices in energy-intensive sectors. As industries increasingly turn towards greener technologies, cryogenic refrigeration stands out as a pivotal advancement in achieving energy efficiency and promoting sustainability.

Cryogenic technology plays a pivotal role in enhancing energy efficiency across various sectors. One of the primary advantages of cryogenic refrigeration systems is their ability to operate at ultra-low temperatures, which significantly reduces energy consumption compared to conventional refrigeration methods. This is particularly beneficial in industries such as food preservation, where maintaining a stable and low temperature is crucial for extending the shelf life of products. By utilizing cryogenic fluids, these systems ensure optimal thermal management, resulting in minimized energy input while maximizing output efficiency.

Moreover, cryogenic refrigeration technologies contribute to reducing greenhouse gas emissions. As industries increasingly focus on sustainability, implementing cryogenic systems can lead to cleaner operations through lower energy consumption and reduced reliance on harmful refrigerants. The high efficiency of cryogenic systems translates into less waste heat production and lower cooling loads, benefiting not only the environment but also operational costs. The shift towards cryogenic technology in energy efficiency represents a forward-thinking approach to tackling climate change while promoting industrial growth and innovation.

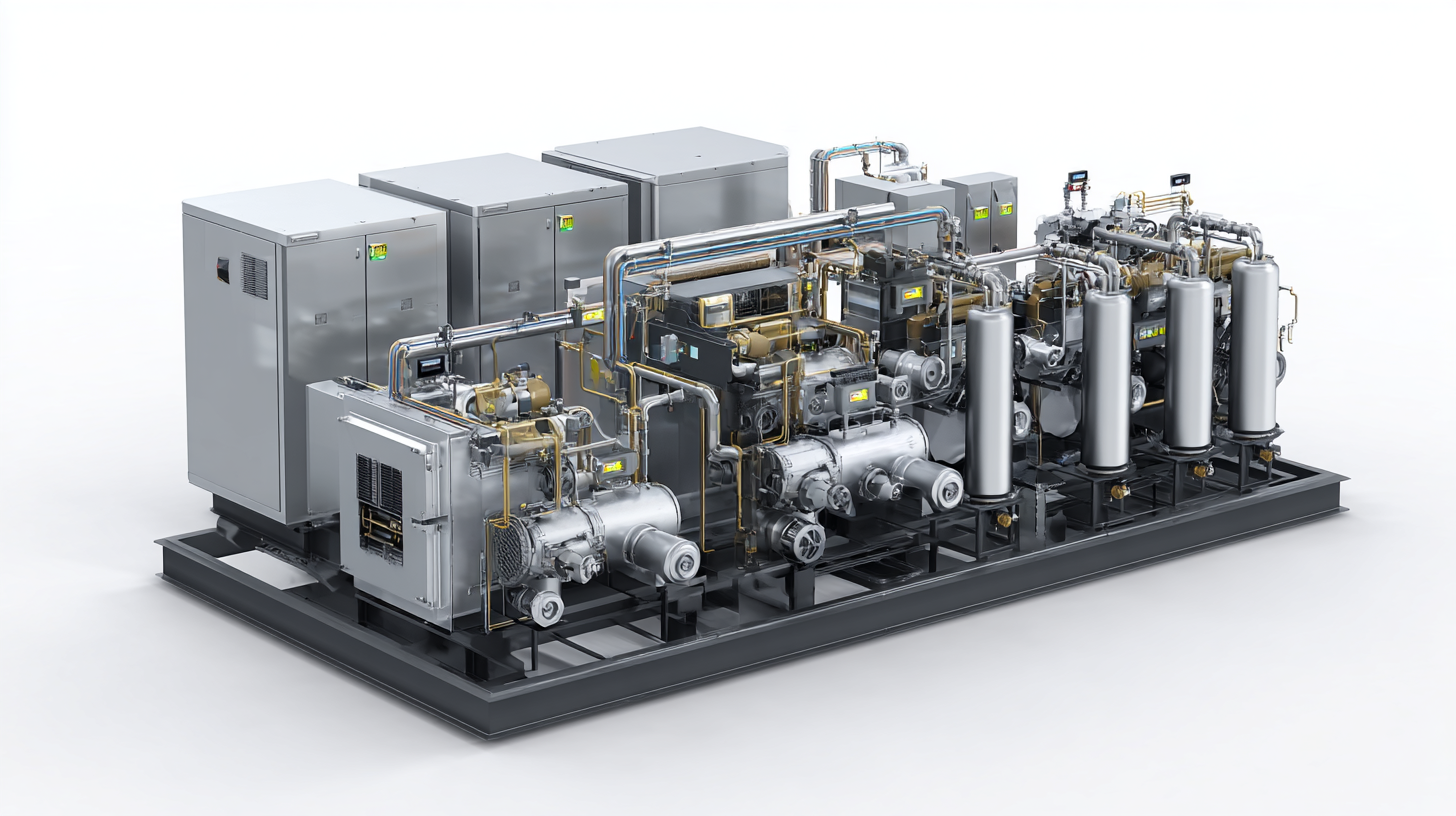

Cryogenic refrigeration systems represent a significant advancement over traditional refrigeration methods, primarily through their superior energy efficiency and environmental benefits. Traditional systems often rely on vapor-compression cycles using refrigerants that can contribute to greenhouse gas emissions. In contrast, cryogenic systems operate by utilizing low-temperature liquids, typically helium or nitrogen, achieving much lower temperatures with reduced energy input. This efficiency not only leads to lower operating costs but also minimizes the ecological impact associated with conventional refrigerants.

When comparing the two methods, it becomes evident that cryogenic refrigeration excels in applications requiring precise temperature control and rapid cooling. Traditional systems can struggle to maintain low temperatures consistently, particularly in industrial settings. Furthermore, cryogenic systems can allow for more compact designs due to their ability to operate at lower temperatures without large compressors, making them more suitable for modern applications where space efficiency is crucial. As industries continue to focus on sustainability and energy conservation, the shift towards cryogenic refrigeration systems is poised to become a standard practice in many sectors.

Cryogenic refrigeration systems are making significant strides across various industries, enhancing energy efficiency and enabling innovative applications. For instance, in the medical field, cryogenic systems are employed for storing and transporting biological samples at ultra-low temperatures, which is crucial for the preservation of vaccines and blood products. According to a report by Grand View Research, the global cryogenic equipment market size was valued at $10.22 billion in 2020 and is expected to expand at a CAGR of 6.0% from 2021 to 2028, reflecting increased demand across health sectors.

In the energy sector, cryogenic technology is transforming how we approach energy storage. Liquid air energy storage (LAES) systems utilize excess energy to cool air to cryogenic temperatures, then release it to generate power during peak demand. The International Energy Agency highlights that integrating such systems could provide up to 20% more efficiency compared to traditional methods. This innovative approach allows for better management of renewable energy resources and enhances grid stability.

**Tip:** When considering cryogenic systems for your business, look into the potential for energy savings and efficiency improvements. Conducting a detailed feasibility study can identify the best applications for your specific industrial needs, ensuring optimal investment outcomes. Remember, continuous advancements in cryogenic technology may lead to even more opportunities in the near future.

As cryogenic refrigeration systems become increasingly vital in various industries, future trends indicate a significant shift toward enhancing energy efficiency and sustainability. Emerging technologies, such as advanced cryogenic coolants and sophisticated control systems, are expected to lower energy consumption while improving performance. For instance, integrating artificial intelligence into cryogenic systems can optimize operational parameters in real-time, ensuring they operate at peak efficiency and adapt to changing cooling demands.

However, the development of cryogenic refrigeration systems is not without challenges. One major hurdle is the high cost associated with the technology and materials needed for low-temperature applications. Additionally, there is a pressing need to address environmental concerns related to the production and disposal of cryogenic fluids. Researchers are focused on finding greener alternatives that minimize ecological impact, which would help align the industry with global sustainability goals. As innovations continue to emerge, the collaborative efforts between academia, industry, and policymakers will be crucial in overcoming these obstacles and driving the future of cryogenic refrigeration.

| Aspect | Current Status | Future Trends | Challenges |

|---|---|---|---|

| Energy Efficiency | Current systems typically achieve 60-80% efficiency | Expected improvements to reach 90% efficiency by 2030 | High initial investment and technology adoption |

| Environmental Impact | Reduction of CO2 emissions by 30% compared to traditional systems | Increased focus on sustainable refrigerants | Regulatory challenges for new refrigerants |

| Technological Innovations | Use of advanced materials and components | Integration with smart grids and IoT technology | Interface standardization and cybersecurity concerns |

| Cost Reduction | Cost currently high, limiting broad adoption | Expecting a 20-30% reduction in costs by 2030 | Supply chain issues and material costs |

| Market Adoption | Growing interest in specific industries | Broad adoption across multiple sectors expected | Consumer awareness and education needed |