-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

Cryogenic Refrigeration Systems are vital in many industries. They provide efficient and reliable cooling for various applications, such as medical technologies and liquefied gases. According to a recent industry report by Research and Markets, the global cryogenic refrigeration market is expected to grow significantly, reaching USD 16.6 billion by 2025. This growth indicates a rising demand for advanced cooling solutions.

Efficiency is essential in cryogenic systems. Even minor improvements can lead to significant energy savings. However, the initial costs and complexity of these systems can be a barrier. Many companies face challenges in selecting the right system that balances performance and budget. The need for regular maintenance also raises questions regarding long-term sustainability.

In the pursuit of enhanced cooling solutions, attention must be given to inefficiencies that can arise. Some industries report performance issues due to poor system design. These factors can impact the overall efficiency of a Cryogenic Refrigeration System. It is crucial for stakeholders to continually reassess their equipment to optimize performance.

Cryogenic refrigeration systems are critical in various industries. They operate at extremely low temperatures, often below -150°C. Their importance spans sectors such as medical, aerospace, and food preservation. According to the International Institute of Refrigeration, the market for cryogenic systems is projected to reach $10 billion by 2025. This is largely due to their efficiency in maintaining temperature-sensitive products.

In the medical field, these systems play a key role in preserving biological samples. For example, they are essential for storing stem cells and vaccines. A study from Cryogenics Journal highlights that rapid cooling can prevent cellular damage, leading to better recovery rates. In aerospace, cryogenic systems enable the storage of liquid fuels at low temperatures. This ensures optimal performance during launches.

While cryogenic systems are beneficial, they come with challenges. Their complexity often leads to maintenance issues. Additionally, the initial investment can be significant. Many industries still grapple with energy consumption concerns. It's essential to improve existing designs for greater efficiency. This remains a key area where innovation is needed.

Cryogenic refrigeration systems play a crucial role in various industries. Understanding their key components is essential for effective cooling solutions. One primary element is the compressor. It compresses gas to high pressure, increasing its temperature. This process is vital for transforming low-temperature gases into usable liquids. Many overlook the significance of maintaining optimal compressor efficiency. Regular checks can prevent performance drops.

Another critical component is the heat exchanger. This device transfers heat between fluids while keeping them separate. A well-designed heat exchanger can significantly improve the system's overall efficiency. However, not all designs are created equal, which can lead to inefficiencies. Users must analyze and adapt their setups based on specific needs.

The expansion valve is equally important. It regulates the flow of refrigerant into the evaporator. Poorly functioning valves can lead to drastic temperature fluctuations. This inconsistency can hinder the operation of sensitive equipment. Regular maintenance and monitoring are necessary. Addressing these issues could enhance the system’s longevity.

| Component | Function | Typical Materials Used | Operating Temperature Range (°C) |

|---|---|---|---|

| Cryocooler | Provides primary cooling by removing heat from the system. | Aluminum, Copper, Stainless Steel | -270 to -150 |

| Heat Exchanger | Transfers thermal energy between two fluids. | Copper, Aluminum | -200 to -100 |

| Expansion Valve | Regulates refrigerant flow into the evaporator. | Brass, Stainless Steel | -260 to -150 |

| Evaporator | Absorbs heat from the environment or product. | Aluminum, Copper | -250 to -80 |

| Compressor | Compresses refrigerant vapor to increase pressure and temperature. | Aluminum, Steel | -200 to -100 |

Cryogenic refrigeration technologies play a crucial role in various applications, from medical storage to aerospace. Understanding the differences can significantly impact efficiency. Liquid nitrogen and helium are two common coolants used. Liquid nitrogen offers a temperature range from -196°C, making it ideal for many applications. However, it is less efficient than liquid helium, which operates at even lower temperatures.

Efficiency is key in choosing a system. A report by the International Institute of Refrigeration highlighted that systems using helium can achieve 30% better cooling efficiency than those using nitrogen. This efficiency comes at a higher cost, as helium is typically more expensive and less abundant. Users must consider both initial investment and long-term operational costs when selecting a system.

Tips: Ensure you evaluate your specific requirements. Sometimes, the cheaper option can lead to higher running costs. Regular maintenance is vital, as efficiency can drop due to wear and tear. Understanding the application is crucial. Each technology serves distinct needs. Make informed choices to optimize your cooling solutions.

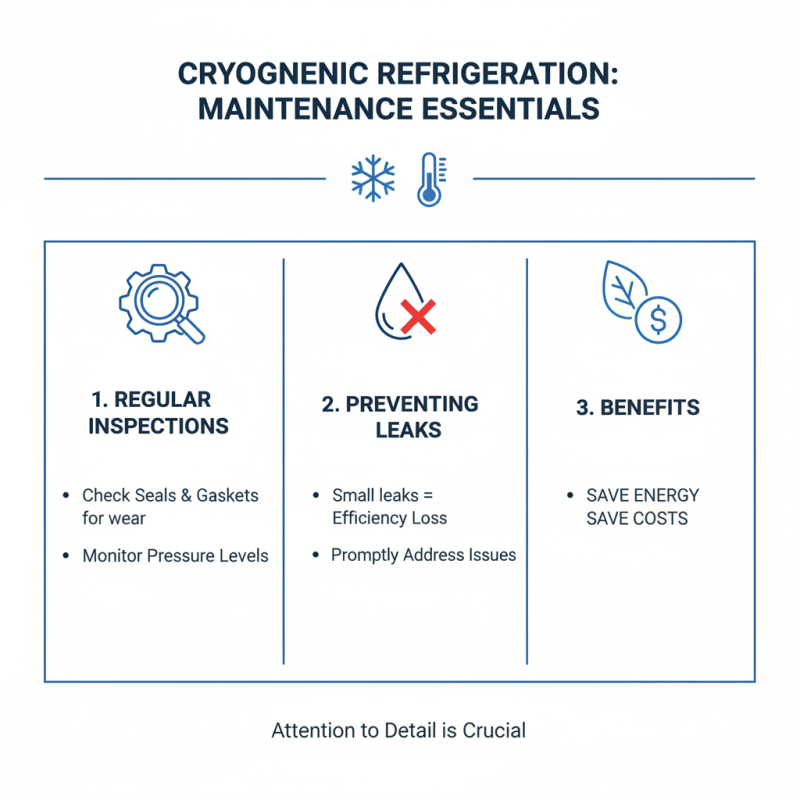

Operating and maintaining cryogenic refrigeration systems require careful attention to detail. Regular inspections are vital. Check seals and gaskets for wear. Monitor pressure levels to avoid overloading the system. Small leaks can lead to significant efficiency loss. Addressing these issues promptly can save both energy and costs.

Training staff is crucial for safe operation. Ensure everyone understands emergency protocols. Mistakes can happen. Even experienced personnel make errors. Keep an open dialogue about potential issues. This encourages a culture of safety and continuous improvement. Regular feedback and discussions can help identify blind spots, leading to better performance.

Maintenance schedules should be strictly followed. Over time, components may degrade. Replace filters and lubricants regularly. Delaying these tasks can lead to system failure. Document all maintenance actions. This log helps track performance over time. Identify patterns that need addressing. Don't wait for issues to escalate. Being proactive is key to maximizing the lifespan of your cryogenic system.

The future of cryogenic refrigeration technology is shaping up to be more efficient than ever. Recent industry reports indicate that advanced techniques could enhance energy efficiency by up to 30%. These innovations focus on improving materials and processes used in refrigeration systems. High-efficiency cryocoolers with improved thermodynamic cycles are at the forefront. Implementing these changes allows for better performance in various applications, including medical and aerospace fields.

Tips: Regular maintenance can significantly improve the efficiency of your cryogenic systems. Keep an eye on the seals and insulation. Small leaks can lead to substantial energy losses.

Moreover, researchers are exploring the potential of using nanotechnology. This could lead to systems that operate with less energy. Integrating artificial intelligence can optimize operations further, predicting maintenance needs before failures occur. However, the adoption of such technologies is gradual and requires a shift in traditional mindsets.

Tips: Consider investing in training for your staff. Understanding new technologies is crucial for maximizing benefits. Evaluate the implementation based on your specific workflow and needs.