-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

A Cryogenic Nitrogen Generator is essential in many industrial applications. Its ability to produce nitrogen at extremely low temperatures makes it valuable. However, using these generators efficiently is crucial for optimal performance.

Effective operation relies on understanding the generator's components. Regular maintenance ensures longevity and efficiency. For instance, checking filters and pressure levels can prevent disruptions. Users often overlook these checks, leading to potential failures. It's essential to adopt a proactive mindset.

Despite advancements, challenges remain. Operational costs can increase if the generator isn’t maintained properly. Regular inspections and proper usage can mitigate these issues. Ultimately, recognizing the importance of routine checks can significantly enhance the lifespan of your Cryogenic Nitrogen Generator.

Cryogenic nitrogen generators play a vital role in various industries. They are essential for applications like food preservation, electronics cooling, and in laboratories. By producing nitrogen at extremely low temperatures, these generators help maintain the integrity of sensitive materials. Industries that require purging, blanketing, or inerting often rely on this technology. The efficiency of these systems can significantly impact operational costs and product quality.

Operating a cryogenic nitrogen generator requires careful attention. Regular maintenance is crucial. Users must monitor pressure levels and ensure proper insulation of the system. Neglecting these aspects can lead to inefficiencies and higher costs. A common issue is the buildup of ice, which can affect performance. Periodic checks can prevent such problems. Moreover, adjustments in the flow rate may be needed to optimize performance based on specific applications.

Training staff on operational protocols is often overlooked. Lack of knowledge can lead to misuse or even accidents. It’s essential to provide clear guidelines and hands-on training for effective management. Users should also seek data analysis on generator performance. This can reveal patterns and help identify areas for improvement. In many cases, refining processes leads to better efficiency and reduced waste. Overall, understanding these systems can greatly enhance their utility across different sectors.

Cryogenic nitrogen generator systems are complex yet efficient. Understanding their key components is crucial for effective use. One primary element is the compressor. It raises the pressure of the incoming air. A high-quality compressor ensures optimal performance and energy efficiency. Regular maintenance is necessary. Neglecting this can lead to decreased efficiency over time.

Another vital component is the heat exchanger. It cools the air before liquefaction. This device should be checked periodically for blockages. Even minor obstructions can hinder performance. Monitoring the heat exchanger's condition can prevent costly repairs later.

Additionally, the storage tank is significant. Liquid nitrogen is stored here. Ensuring the tank is properly insulated is critical for efficient use. Loss of nitrogen through evaporation can reduce performance drastically. Regular inspections may be required to maintain its integrity. A proactive approach is necessary to ensure all components function effectively.

Efficient operation of cryogenic nitrogen generators relies on maintaining optimal conditions. These generators work best at controlled temperatures and pressures, ensuring consistent output. Regular monitoring is essential. A study by the International Cryogenics Institute highlighted that maintaining a cryogenic temperature range leads to a 15% increase in nitrogen purity.

Maintenance practices also play a crucial role. Regular inspections of filters and valves help avoid system failures. Dust and contaminants can significantly impact performance. Surprisingly, many operators overlook this aspect. According to industry reports, neglecting regular checks can reduce efficiency by up to 20%.

Implementing a proper maintenance schedule is vital. However, some facilities may struggle with adhering to these schedules. It's often easy to underestimate the importance. Simple practices, like lubricating moving parts, can prevent wear and tear. These steps may seem tedious but have lasting effects on performance and longevity. Regular training for operators can improve awareness and prevent mishaps.

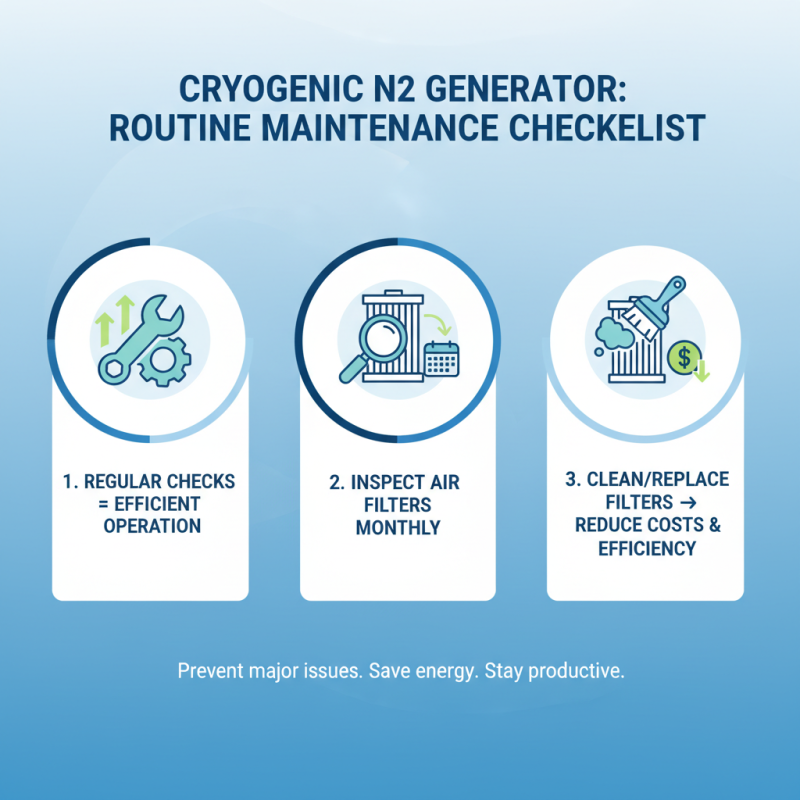

Routine maintenance is key to keeping your cryogenic nitrogen generator running efficiently. Regular checks can prevent major issues later. Start by inspecting the air filters. Clean or replace them every month. Clogged filters can lead to reduced efficiency and increased energy costs.

Another important tip is to monitor the pressure and temperature gauges. Abnormal readings might indicate underlying problems. Address these issues promptly. Regularly inspect the pumps and valves for leaks. Even small leaks can cause performance drops.

Keep a maintenance log for tracking repairs and checks. This practice helps identify recurring issues. It also ensures that nothing is overlooked. Lastly, regularly purge the system to remove impurities. A clean system operates more efficiently. Take these simple steps. They can drastically improve performance and longevity.

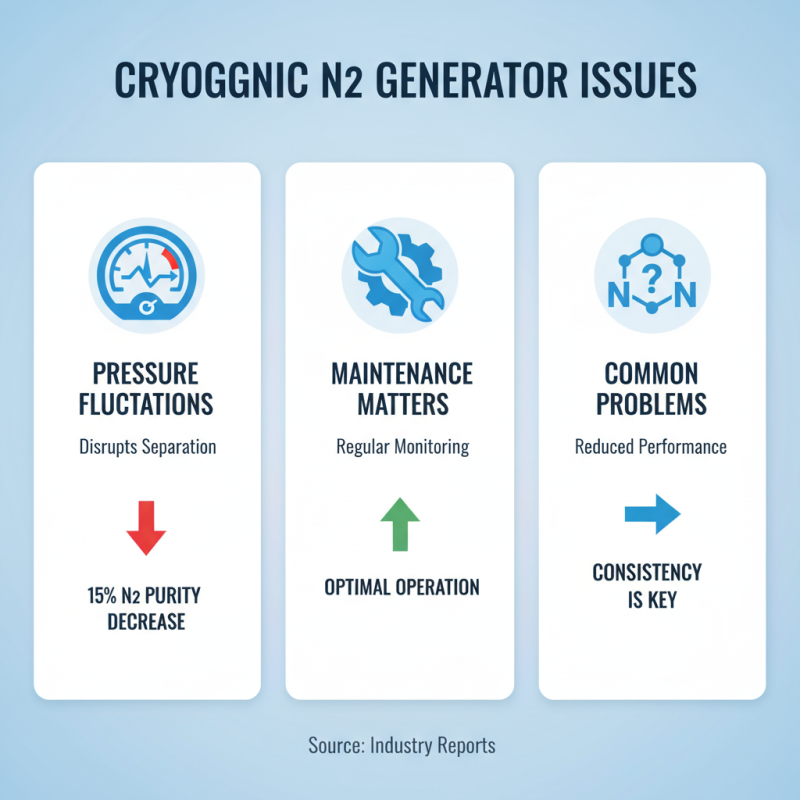

Cryogenic nitrogen generators can face several common issues that hinder their performance. A frequent problem is pressure fluctuations. These variations can disrupt the separation process. Regular monitoring of system pressure can identify inconsistencies. Industry reports show that pressure issues often lead to a 15% decrease in nitrogen purity. Correcting these fluctuations helps maintain optimal operation.

Another issue is contamination within the system. Contaminants like moisture can create ice buildup in the components. This can lead to blockages and inefficiencies in production. It's advisable to regularly check filters and traps. Neglecting these areas can result in subpar gas quality. Proper maintenance can improve efficiency significantly, often by around 20% according to technical studies.

Operator errors also play a role in system inefficiencies. Misreading gauges or valves can lead to incorrect settings. Statistics indicate that human error accounts for up to 25% of operational issues in these systems. Training personnel regularly is crucial. Operators should understand the machinery deeply to prevent mistakes. Investing in knowledge can mitigate operational risks effectively.