-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

Cryogenic Helium Refrigeration has emerged as a crucial technology in various scientific and industrial applications, ranging from superconducting magnets in particle accelerators to advanced cryogenic systems used in medical imaging. Renowned expert Dr. Emily Johnson, a leading physicist in the field, emphasizes the significance of this technology by stating, "The efficiency of Cryogenic Helium Refrigeration can dramatically enhance performance across multiple disciplines, enabling breakthroughs that were previously unattainable."

As industries increasingly adopt this innovative refrigeration method, understanding how to implement Cryogenic Helium Refrigeration effectively becomes paramount. This introduction aims to explore the principles behind this technology, its advantages, and best practices for ensuring optimal performance in diverse applications. By harnessing the unique properties of helium at cryogenic temperatures, we can facilitate advancements in research and development, ultimately leading to improved outcomes in both technological and medical domains.

In the following sections, we will delve deeper into the mechanisms of Cryogenic Helium Refrigeration, the challenges it presents, and the strategies that can be employed to maximize its efficiency and reliability. As we move forward, it will become evident that mastering this technology is not just advantageous; it is essential for those seeking to push the boundaries of what is possible in their respective fields.

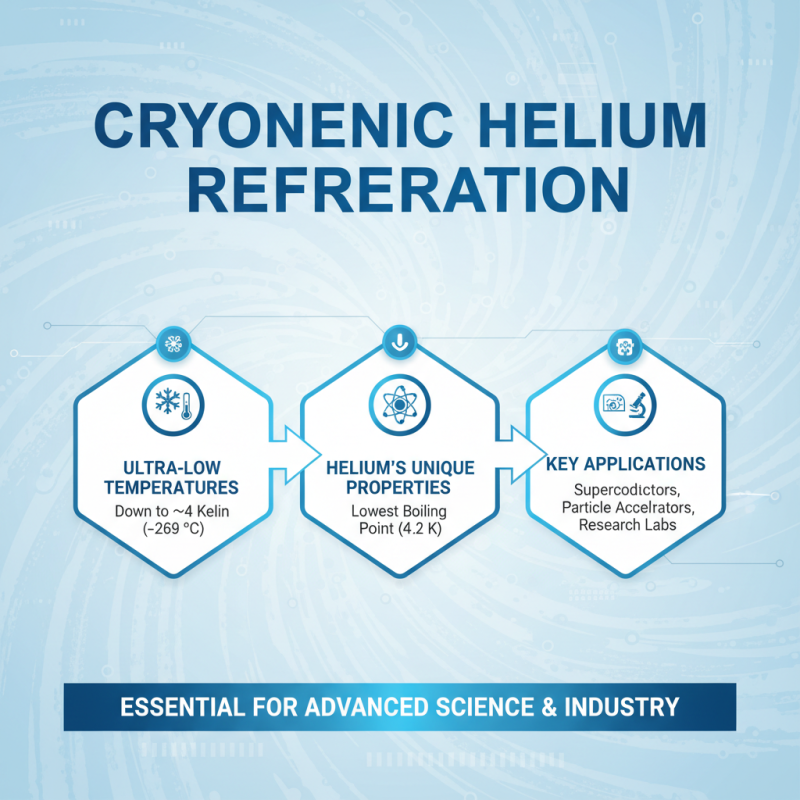

Cryogenic helium refrigeration technology plays a crucial role in a variety of scientific and industrial applications, primarily due to its ability to reach temperatures significantly lower than those achievable with conventional refrigeration methods. This technology utilizes the unique properties of helium, particularly its low boiling point, which allows it to remain in a gaseous state at extremely low temperatures. By exploiting the thermodynamic processes of helium, this refrigeration method effectively cools materials and equipment that must operate at cryogenic conditions, such as superconductors, particle accelerators, and various laboratory apparatus.

In implementing cryogenic helium refrigeration, understanding the underlying principles is essential. The process typically involves the compression of helium gas, which is then cooled and expanded to achieve low temperatures. The efficiency of this system depends on factors such as the design of the refrigeration cycle, as well as the specific requirements of the application it serves. Furthermore, careful management of helium resources is important, as it is a finite resource and increasingly valuable in high-tech applications. By advancing research in this area and optimizing the technology, users can enhance performance while minimizing operational costs, paving the way for innovations in fields ranging from medical imaging to quantum computing.

Cryogenic helium refrigeration systems play a crucial role in many cutting-edge applications across various fields. One key area is in the realm of medical technology, particularly in magnetic resonance imaging (MRI) machines. These machines require extremely low temperatures to maintain the superconducting magnets necessary for high-resolution imaging. By utilizing cryogenic helium refrigeration, the system efficiently cools these magnets, ensuring they operate at optimal performance and enhancing diagnostic capabilities.

Another significant application of cryogenic helium refrigeration is in the field of particle physics. Large particle accelerators, such as those used in research for fundamental particle interactions, rely on superconducting magnets to guide and focus particle beams. The low temperatures provided by helium refrigeration systems allow these magnets to function without electrical resistance, which is essential for achieving the high magnetic fields required for effective acceleration. This process not only facilitates groundbreaking research in physics but also contributes to advancements in other related sciences and technologies.

In aerospace engineering, cryogenic helium refrigeration systems are employed to maintain the necessary temperatures for liquid rocket fuels. By keeping fuels and oxidizers at cryogenic temperatures, engineers can ensure their efficiency and stability. This is particularly important for missions involving long-duration space travel where temperature control is crucial for performance and safety.

| Application Area | Typical Operating Temperature (K) | Cooling Power (W) | Key Benefits |

|---|---|---|---|

| Superconducting Magnets | 4.2 K | 1500 W | High-efficiency magnetic field generation |

| Cryogenic Particle Accelerators | 1.9 K | 2000 W | Enhanced particle collision rates |

| Infrared Sensors | 77 K | 500 W | Improved sensitivity and resolution |

| Cryogenic Refrigeration for Medical Imaging | 4.2 K | 1000 W | Higher image quality and lower noise |

| Quantum Computing | 10 mK | 300 W | Stable environment for qubit operation |

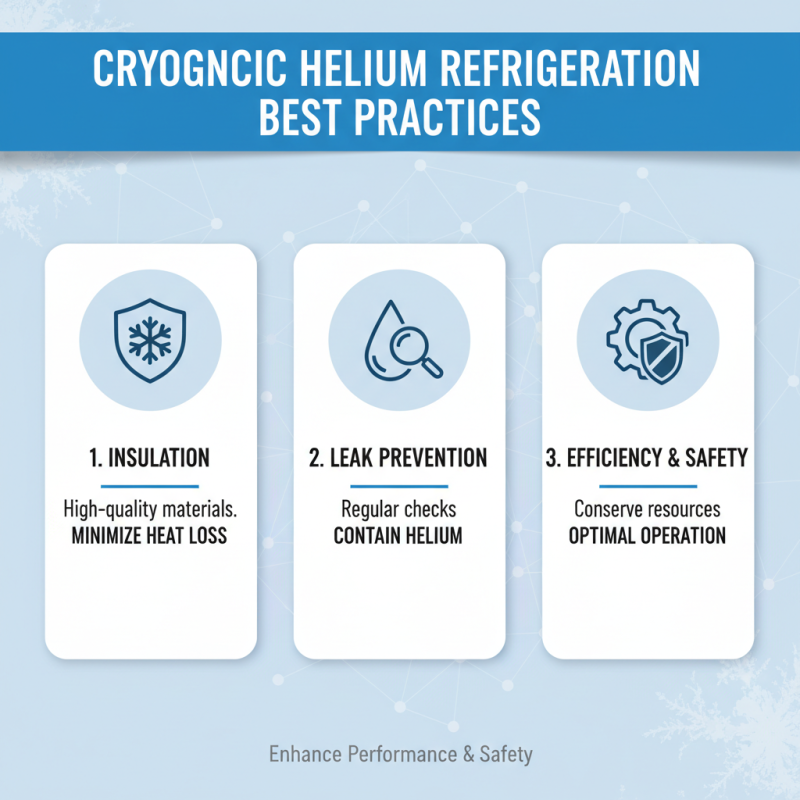

When implementing cryogenic helium refrigeration, it’s essential to establish best practices that enhance efficiency and safety. First, proper insulation is critical. Using high-quality materials to minimize thermal losses can significantly improve the system’s performance. Focusing on leak prevention is equally important; regular checks and maintenance can ensure that the helium remains contained, preventing waste and potential hazards. This not only conserves resources but also maintains optimal operational conditions during use.

Another key factor is the careful calibration of temperature controls. Precise monitoring and adjustment of temperatures allow for tailored cooling solutions that cater specifically to the application’s needs. Employing advanced sensors can provide real-time data, enabling quick responses to any fluctuations. Additionally, comprehensive training for personnel managing these systems is vital. Understanding the intricacies of cryogenic processes ensures that the equipment is operated safely and efficiently, ultimately leading to better outcomes in various applications, from medical technologies to scientific research.

Maintaining and optimizing cryogenic helium refrigeration systems is crucial for enhancing their efficiency and prolonging service life. Regular maintenance routines should include checks on insulation integrity, leak detection, and monitoring of system pressures and temperatures. Ensuring that all components, such as compressors, cold heads, and heat exchangers, are functioning correctly can prevent unnecessary energy consumption and maintain optimal cooling performance. Implementing a structured maintenance schedule that addresses these aspects can significantly reduce downtime and avoid costly repairs.

In addition to routine maintenance, optimizing the operational parameters of the refrigeration system is key to maximizing its effectiveness. This can involve fine-tuning settings based on specific application demands, adjusting the flow rates of helium, and ensuring that the systems operate under the most efficient thermal conditions. Utilizing advanced control algorithms and sensors can enhance the precision of these adjustments, allowing for real-time monitoring and management. By continuously analyzing performance data, operators can identify areas for improvement and make proactive changes to enhance overall system efficiency.

This chart illustrates the refrigeration efficiency of cryogenic helium systems in various applications. MRI machines achieve the highest efficiency at 95%, followed by satellite systems and superconducting magnets, while particle accelerators and cryogenic freezers also maintain commendable efficiency levels.

When using cryogenic helium refrigeration, safety should always be a paramount concern due to the extreme low temperatures and potential hazards associated with the handling of helium. First and foremost, personal protective equipment (PPE) such as insulated gloves, goggles, and protective clothing should be worn at all times. This protects users from cold burns and exposure to cryogenic liquid, which can cause severe injuries. Workspaces should be equipped with proper ventilation to prevent the accumulation of helium gas, which is odorless and colorless but can displace oxygen in the air.

Moreover, proper training is essential for personnel involved in cryogenic helium refrigeration. Understanding the properties of helium, the behavior of cryogenic materials, and emergency procedures is critical. Equipment should be routinely inspected for leaks or defects to ensure safe operation. Additionally, protocols should be established in the event of a spill or equipment failure, ensuring that everyone in the vicinity knows how to respond quickly and effectively to minimize risk. These precautions can significantly reduce the likelihood of accidents and enhance the overall safety of cryogenic applications.