-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

In both industrial and home settings, the safe handling of compressed gas is paramount to preventing accidents and ensuring the well-being of individuals and the environment. According to Dr. Emily Carter, a leading expert in compressed gas safety, “Understanding the properties and risks associated with compressed gases is crucial for anyone working in environments where these gases are present.” Her insights emphasize the importance of proactive measures and comprehensive safety protocols.

Compressed gas can be found in a multitude of applications ranging from medical facilities to manufacturing plants and even hobbyist workshops. While their utility is undeniable, their potential hazards make it essential for users to be well-informed about the risks involved. Education and training can significantly reduce the likelihood of accidents and ensure that both industrial workers and home users understand the necessary precautions to take when handling these materials.

With this in mind, we present the top ten compressed gas safety tips designed to guide both professionals and enthusiasts alike. By following these guidelines, individuals can cultivate a safer environment and minimize the potential for harmful incidents involving compressed gases.

Compressed gases are essential in both industrial and home settings, yet they pose significant hazards if not managed properly. According to the U.S. Occupational Safety and Health Administration (OSHA), there are over 300 types of compressed gases used in various applications, classified mainly into three categories: flammable, toxic, and inert gases. Each category presents distinct hazards that require specific precautionary measures. For example, flammable gases like acetylene and propane can create explosive atmospheres if not handled in well-ventilated areas, while toxic gases, such as chlorine and ammonia, can cause serious health issues upon exposure.

The proper understanding of these compressed gas types can significantly reduce risks. A report by the National Fire Protection Association (NFPA) indicates that nearly 50% of all industrial gas accidents are a result of improper storage or handling practices. This underscores the importance of labeling cylinders correctly, maintaining proper storage conditions, and conducting regular inspections to prevent leaks and other hazards. Furthermore, training employees and residents in recognizing the signs of gas leaks, using appropriate personal protective equipment, and understanding emergency procedures can enhance safety and compliance in both industrial and domestic environments.

| Tip Number | Safety Tip | Compressed Gas Type | Hazards |

|---|---|---|---|

| 1 | Always store cylinders upright and secured | Oxygen, Acetylene | Potential for tip-over or explosion |

| 2 | Use proper regulators and fittings for each gas | Various Gases | Risk of leaks or bursts |

| 3 | Never use oil on oxygen fittings | Oxygen | Increased risk of fire or explosion |

| 4 | Ensure proper ventilation in confined spaces | Carbon Dioxide | Risk of asphyxiation |

| 5 | Check for leaks using soapy water | All Gases | Potential for increased pressure or fire |

| 6 | Wear appropriate personal protective equipment (PPE) | All Gases | Potential for injury |

| 7 | Label cylinders clearly | All Gases | Confusion leading to improper handling |

| 8 | Avoid exposure to extreme temperatures | All Gases | Potential for pressure buildup |

| 9 | Have an emergency plan in place | All Gases | Ensures quick response during incidents |

| 10 | Regularly inspect and maintain equipment | All Gases | Avoids malfunctions and accidents |

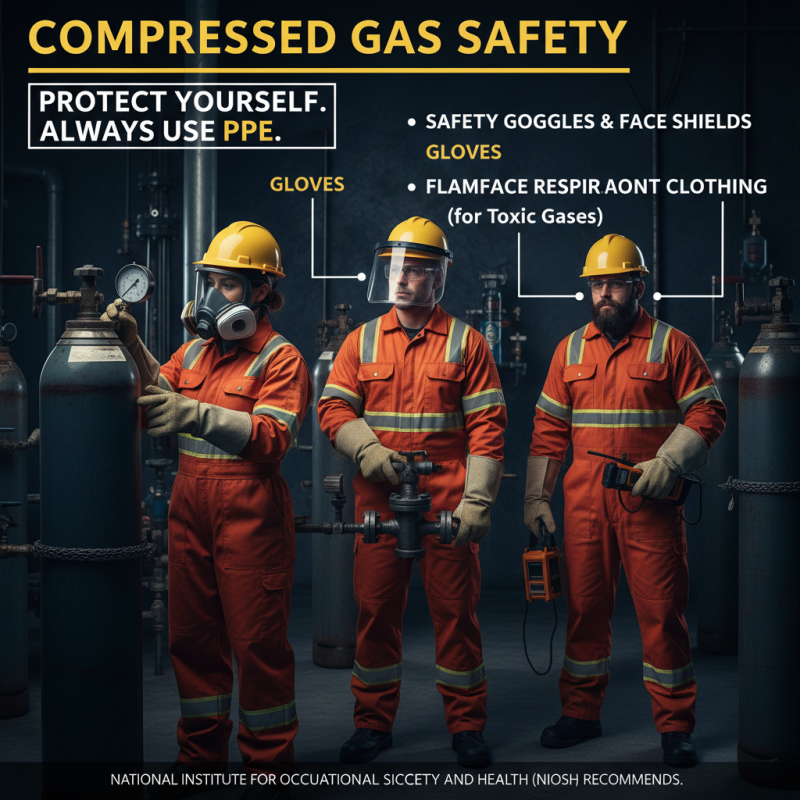

When handling compressed gases, the importance of personal protective equipment (PPE) cannot be overstated. According to the National Institute for Occupational Safety and Health (NIOSH), inadequate use of PPE in gas handling can lead to serious injury or even fatal accidents. In environments where compressed gases are prevalent, workers should wear appropriate PPE, including safety goggles, face shields, gloves, and flame-retardant clothing. NIOSH recommends that full-face respirators be utilized when working with toxic gases to ensure adequate respiratory protection, particularly in confined spaces where gas leakage may occur.

In the industrial sector, a report by the Occupational Safety and Health Administration (OSHA) states that over 52,000 injuries related to hazardous materials occur annually, with a significant portion attributable to improper or inadequate PPE. As such, employers must prioritize rigorous training programs to ensure that employees understand the importance of safe handling practices and the correct use of PPE. This training should emphasize the need for regular inspections of safety gear, ensuring that all equipment is compliant with industry standards, and replacing any damaged items promptly. Awareness and education play crucial roles in minimizing risks associated with compressed gas handling, underscoring the need for diligence in PPE protocols.

Effective storage and labeling of compressed gas cylinders are crucial components of safety protocols in both industrial and home environments. According to the Compressed Gas Association, nearly 2,000 incidents involving compressed gases occur annually, often due to improper handling and storage practices. To mitigate these risks, it is essential to keep cylinders stored in a well-ventilated area, away from combustible materials, and secured in an upright position to prevent tipping. Regular inspections should be conducted to check for any signs of corrosion or damage, which could lead to hazardous leaks.

Labeling practices also play a pivotal role in maintaining safety. Each cylinder should have clearly visible labels indicating the gas contained within, associated hazards, and handling requirements. The Occupational Safety and Health Administration (OSHA) mandates that labels must conform to established standards to ensure quick identification and minimize the risk of confusion. According to the National Fire Protection Association (NFPA), about 60% of all gas-related accidents could be traced back to inadequate labeling and warning systems. By implementing stringent storage and labeling protocols, both industrial facilities and home users can significantly reduce the likelihood of accidents and create a safer environment for all.

When handling compressed gases, whether in industrial settings or at home, it is crucial to follow safe handling techniques to prevent accidents and ensure the safety of everyone involved. First and foremost, always store compressed gas cylinders in an upright position and secure them using appropriate restraints to prevent tipping or falling. This ensures stability and minimizes the risk of leaks or ruptures. Additionally, it is essential to keep these cylinders in well-ventilated areas away from heat sources, flammable materials, and any potential electrical hazards that could cause ignition or mishaps.

During transport, proper procedures must be followed to safeguard both the gas and the individuals involved. When moving cylinders, use suitable carts and equipment to avoid manual lifting whenever possible. Always ensure that the cylinder caps are securely fastened to protect the valves during transit. Operators should wear appropriate personal protective equipment, such as gloves and goggles, to mitigate risks associated with any accidental releases. Furthermore, maintaining clear communication among team members is vital to coordinate movements safely and effectively, ensuring that everyone remains informed about potential hazards associated with the gases being transported. By adhering to these safe handling techniques, the risks associated with compressed gas usage can be significantly reduced.

This chart demonstrates the importance rating of various safety tips for handling compressed gases. Each tip is rated on a scale from 1 to 10, helping users to prioritize safety measures whether in industrial settings or at home.

In the realm of compressed gas safety, understanding emergency response protocols is critical to minimize risks associated with gas incidents. According to the Compressed Gas Association, over 40% of industrial gas accidents result from improper handling or storage, highlighting the need for robust emergency procedures.

Facilities that utilize compressed gases should develop and regularly practice an emergency response plan that addresses potential leak scenarios, fire hazards, and equipment failures. This plan should encompass immediate actions to be taken, such as evacuating personnel, securing the area, and notifying emergency services, ensuring that all staff are trained and aware of their roles.

Facilities that utilize compressed gases should develop and regularly practice an emergency response plan that addresses potential leak scenarios, fire hazards, and equipment failures. This plan should encompass immediate actions to be taken, such as evacuating personnel, securing the area, and notifying emergency services, ensuring that all staff are trained and aware of their roles.

Moreover, the National Fire Protection Association recommends that organizations conduct regular drills to test their emergency response effectiveness. This proactive approach not only helps identify weaknesses in the response plan but also reinforces safe working practices among employees.

A well-prepared workforce is essential, as studies indicate that timely and informed responses can reduce the severity of incidents by up to 60%. Therefore, ongoing training and clear communication regarding safety procedures are vital components in safeguarding personnel and property during compressed gas incidents.

A well-prepared workforce is essential, as studies indicate that timely and informed responses can reduce the severity of incidents by up to 60%. Therefore, ongoing training and clear communication regarding safety procedures are vital components in safeguarding personnel and property during compressed gas incidents.