-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

Choosing the right cryogenic storage tank is crucial for various industries. These tanks are designed to hold liquefied gases at extremely low temperatures. Different applications demand different specifications.

One must consider factors like capacity, insulation, and material. A well-suited cryogenic storage tank can enhance efficiency. However, selecting the wrong one might lead to inefficiencies or even safety hazards. Attention to detail is essential in this process.

Many overlook the importance of regulatory compliance. Tanks must meet industry standards for safety and performance. This adds another layer of complexity. Reflecting on past choices can guide future decisions. Balancing needs and costs is often challenging. It requires thorough research and careful consideration.

When considering cryogenic storage tanks, it's essential to grasp the fundamentals. Cryogenic tanks are designed to store gases like nitrogen and helium at extremely low temperatures. These tanks maintain temperatures below -150 degrees Celsius. Understanding the specifics can significantly influence your choice.

Material plays a critical role in tank selection. Stainless steel is common due to its durability. However, it can be heavy and costly. Some tanks are constructed from aluminum, which is lighter but may not withstand all conditions. Each material has its pros and cons, making it vital to assess your specific needs carefully.

Think about the storage capacity. Smaller tanks are easier to manage but may not meet large demands. Conversely, larger tanks take up more space and may lead to waste if not utilized efficiently. Reflecting on your operational needs can help you avoid under or over-purchasing. Balancing capacity and material choice requires thoughtful consideration and planning.

Choosing the right cryogenic storage tank starts with identifying your specific storage requirements. Consider the type of materials you need to store. Different gases like nitrogen or helium may require unique tank designs. Understand the volume. Will you need a small tank for limited storage or a larger unit for bulk needs?

Think about temperature control as well. Some materials require extremely low temperatures. Ensure the tank can maintain these conditions safely. Safety features are crucial as well. Is the tank equipped with pressure relief mechanisms? This can prevent dangerous situations during storage.

**Tips:** Always assess space limitations. Measure where you'll place the tank carefully. You might need extra room for maintenance. Also, consider accessibility. A tank that's hard to reach can complicate refills.

Don't forget about future needs. Your storage requirements might change. A small tank today may not suffice tomorrow. Picture your growth and plan accordingly. It's better to invest in a versatile solution.

This chart displays the different types of cryogenic storage tanks based on their storage capacities (in liters). Understanding these capacities can help in selecting the correct tank for specific needs.

When selecting a cryogenic storage tank, it’s crucial to consider the specific types available. There are generally two main designs: vertical and horizontal tanks. Vertical tanks are often space-saving and allow for easy inspection. They can also be easier to maintain in some scenarios. On the other hand, horizontal tanks tend to have a larger volume, making them suitable for various industrial needs.

Material choice also plays a significant role. Stainless steel is common for its durability and resistance to corrosion, but it can be heavy and expensive. Alternatives like aluminum may offer a lighter option but might not provide the same longevity. Each material has its own set of advantages and drawbacks, which need careful evaluation.

Moreover, insulation types are varied and impact performance. Vacuum insulation is effective but might require more upkeep. Other systems could be less efficient. Make sure to review the long-term costs versus immediate savings. These considerations can influence your decision significantly, so it’s vital to weigh them properly.

Ultimately, there isn’t a one-size-fits-all solution, and a bit of trial and error may be necessary to find the best fit for your requirements.

When selecting a cryogenic storage tank, safety features greatly impact your choice. Tanks must have robust insulation to prevent heat transfer. Without proper insulation, the stored materials can evaporate. This leads to loss and potential hazards. Any tank should meet local compliance standards. Make sure it has necessary certifications.

Regular maintenance is essential for safety. Check for any signs of corrosion or damage. These can compromise tank integrity. A pressure relief valve is vital. It ensures safe venting in case of excessive pressure. An effective monitoring system can alert you of any problems. An unmonitored tank can pose serious risks.

Consider the materials used in the tank. They should withstand extreme temperatures without degrading. The wrong materials can lead to failure. Always evaluate the manufacturer's safety record. Even minor oversights in safety can lead to catastrophic failures. Reflecting on these details ensures a safer choice for your needs.

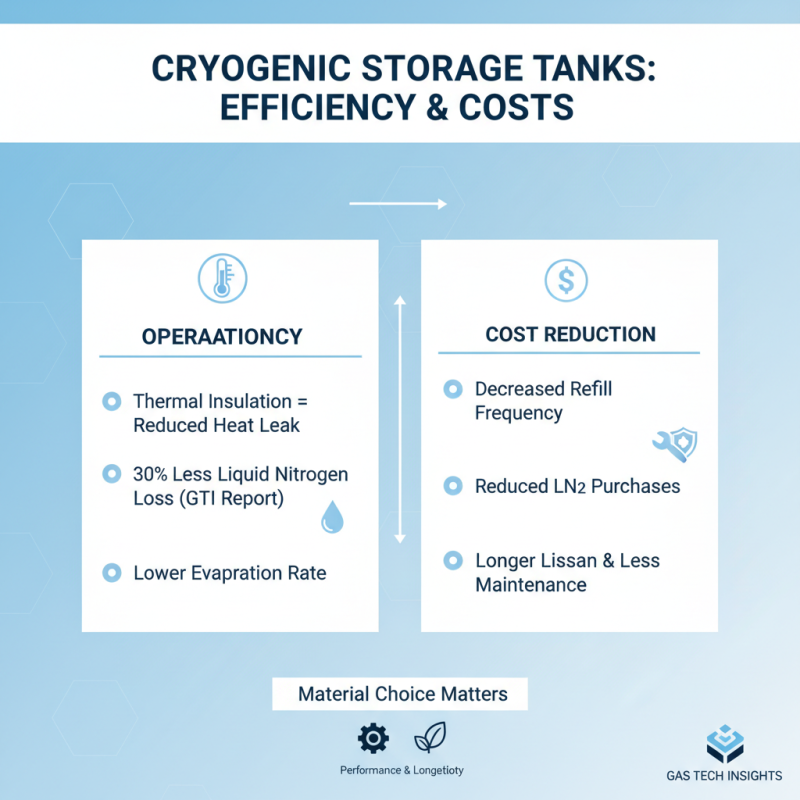

When assessing cryogenic storage tanks, operational efficiency and costs are crucial. Different tank designs offer varying thermal efficiencies. According to a report by the Gas Technology Institute, properly insulated tanks can reduce liquid nitrogen losses by 30%. Reduced losses lead to lower operational costs. Moreover, the choice of materials impacts longevity and maintenance expenses.

Tips: Consider tank positioning and sunlight exposure. Shadows from adjacent structures can help maintain temperatures.

In commercial settings, costs often fluctuate. Industry analyses indicate that upfront investments can be substantial. However, long-term savings from reduced energy consumption often justify the expense. It's essential to weigh the tank's lifespan and maintenance requirements against its initial cost. Some users overlook frequent maintenance, leading to efficiency drops over time.

Tips: Create a maintenance schedule. Regular checks can reveal issues before they escalate. Keeping records is vital for system efficiency.