-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

Choosing the right Cryogenic Dewar for your needs can be daunting. As Dr. Emily Carter, a leading expert in cryogenic technologies, once said, "Understanding your specific requirements is key to selecting the ideal Cryogenic Dewar." This insight highlights the importance of evaluating your unique applications.

In 2026, multiple options are available, but not all are suitable. Each Cryogenic Dewar has distinct features that cater to various industries. Some are designed for research laboratories, while others suit medical applications. Recognizing the differences can be overwhelming. You might find yourself pondering various factors, from storage capacity to ease of handling.

Choosing the wrong Cryogenic Dewar can lead to significant issues. It could impact experiments or medical procedures, potentially wasting time and resources. Being aware of these challenges can guide you in making an informed decision. Remember, the right choice can enhance efficiency and safety in your work.

Cryogenic Dewars play a crucial role in scientific and industrial applications. They are specially designed to store liquefied gases at extremely low temperatures. Understanding their fundamentals can significantly enhance your selection process in 2026.

These Dewars come in various sizes and types. Smaller models are ideal for laboratories, while larger ones serve industry needs. For instance, a standard liquid nitrogen Dewar with a 10-liter capacity can typically maintain temperatures below -196°C for extended periods. This temperature preservation is vital for materials science and biobanking applications. A report from the Cryogenic Society indicates that these Dewars can improve material durability by over 30% when used properly.

Despite their benefits, not all Dewars are created equal. Many users overlook the importance of insulation and design. Some models use outdated materials, leading to significant heat transfer. As a result, users may face challenges in maintaining temperatures. The average rate of evaporation can reach up to 1-2% per day in poorly insulated Dewars. This statistic highlights the need for careful selection based on intended use.

| Dewar Type | Capacity (Liters) | Temperature Range (°C) | Applications | Weight (kg) |

|---|---|---|---|---|

| Liquid Nitrogen Dewar | 20 | -196 to -150 | Cryopreservation, Cooling | 15 |

| Liquid Helium Dewar | 30 | -273 to -220 | Superconductivity Research | 25 |

| Cryogenic Storage Dewar | 50 | -196 to 0 | Biological Samples, Laboratory Uses | 35 |

| Transport Dewar | 10 | -196 to -150 | Transport of Cryogenic Materials | 8 |

| Research Dewar | 15 | -196 to -40 | Research Laboratories, Testing | 12 |

Choosing the right cryogenic dewar in 2026 requires careful consideration of several key factors. The capacity of the dewar is crucial. It varies significantly, with many options ranging from a few liters to over a thousand liters, thereby directly impacting storage and transport efficiency. According to industry reports, larger dewars often provide better thermal performance but come with increased weight, which may challenge maneuverability.

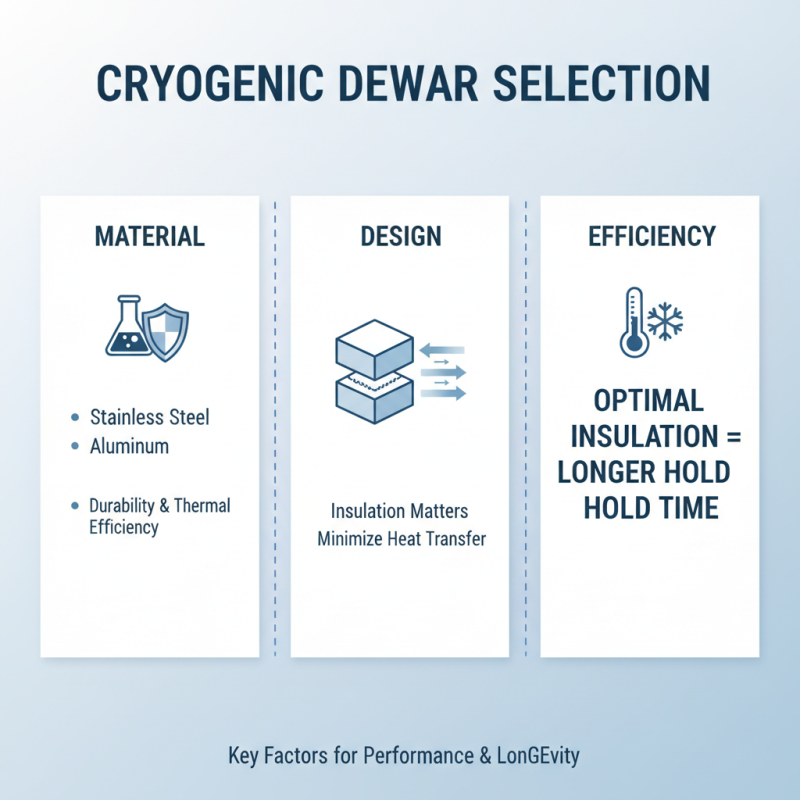

Material quality is another critical factor. Dewars are typically made from stainless steel or aluminum. Stainless steel dewars tend to offer higher durability and better insulation, but they also carry a heavier price tag. In contrast, aluminum options can be more lightweight and economical, though they may not retain temperatures as effectively. The choice ultimately depends on your specific needs and budget constraints.

**Tip**: Always evaluate your proper storage temperature. Understand the specific temperatures required for your gases. Additionally, consider portability if you plan to transport the dewar frequently.

On the other hand, don’t forget about safety features. Some dewars come equipped with pressure relief valves and rupture disks. Industry standards are essential for ensuring safe usage. Regular maintenance and inspections are always recommended, as neglect can lead to hazardous situations.

**Tip**: Be mindful of the insulation layer's condition. It can degrade over time, affecting performance. Always store dewars upright to prevent any leakage.

When selecting a cryogenic dewar, material and design play crucial roles. The efficiency of a dewar largely depends on its insulation. Most dewars utilize materials like stainless steel or aluminum. These metals provide durability and thermal efficiency. However, the design also matters. A poorly designed dewar can compromise its insulating capabilities, leading to quicker heat transfer.

Consider the shape of the dewar. A wider base can prevent tipping. But a taller, slimmer design may save space. Aesthetics can be exciting, yet practical features should be prioritized. Vacuum insulation is common, but not all designs effectively maintain this vacuum. You might find that some dewars have microscopic leaks. These leaks can seriously impact performance.

In the quest for the perfect dewar, it’s essential to reflect on previous experiences. Did measurements fit your requirements? Was the insulation sufficient? Some users might overlook the importance of keeping it clean. Dust and grime can affect heat transfer as well. Choosing the right dewar is about understanding materials and designs, alongside personal needs. Always think twice before making a decision.

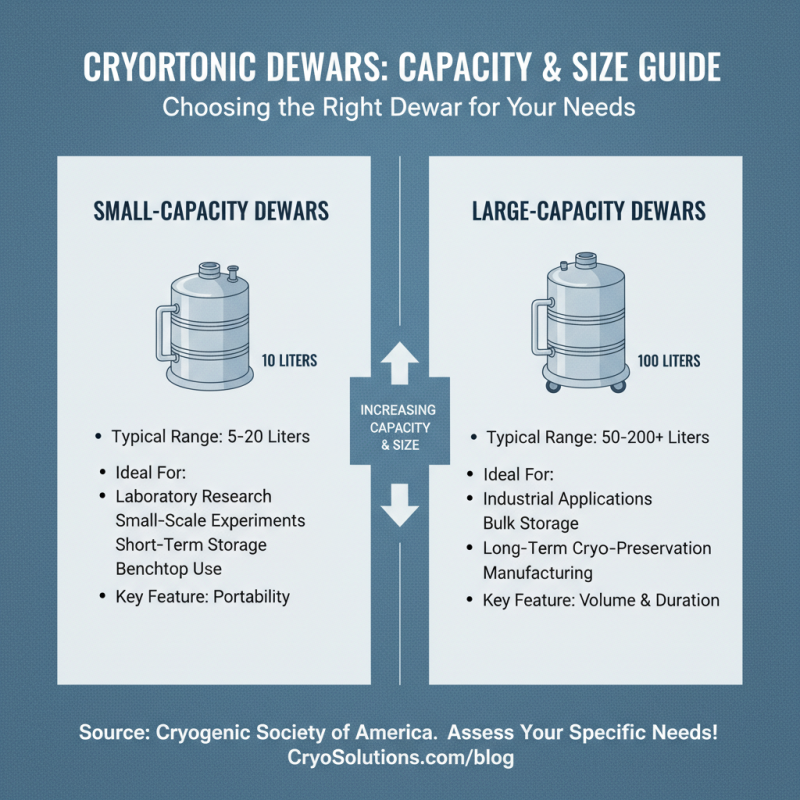

Choosing the right cryogenic Dewar is essential for various applications. When comparing capacity and size options, assessing your specific needs is crucial. According to the Cryogenic Society of America, Dewars come in various sizes, ranging from small 10-liter units to larger 100-liter models. Each serves distinct purposes, from laboratory experiments to industrial applications.

Capacity matters greatly. A 10-liter Dewar may suffice for a small research lab. However, larger operations may require capacities up to 500 liters. Scientists often underestimate their needs, leading to frequent refills and interruptions. A study by the American Institute of Physics highlights that poor planning can result in wasted time and resources, emphasizing the importance of forecasting your liquid nitrogen usage accurately.

Size is equally important. Smaller Dewars are portable but may lack insulation. Larger ones provide better thermal efficiency but require more storage space. Striking a balance between portability and capacity is often challenging. Many users find themselves with inadequate space, forcing them to compromise. Understanding these nuances helps ensure that you choose a Dewar that fits well within your operational needs, both in terms of space and efficient usage.

As we move into 2026, advancements in cryogenic dewar technology are transforming industries. The demand for efficient insulation and advanced materials is growing. Innovative designs now focus on reducing weight while enhancing thermal performance. This shift helps institutions better manage their cryogenic storage needs.

Emerging trends include the use of vacuum-insulated panels and improved cryogenic materials. These innovations significantly reduce heat transfer, minimizing energy costs. The integration of smart technology into dewars offers real-time monitoring. Users can track temperature changes and fluid levels easily. However, this technology can be complex and may require user training to ensure proper use.

Challenges remain in finding the right balance between cost and performance. Some users may find it difficult to determine which features matter most for their applications. Overlooking specific requirements could lead to inefficient storage solutions. Users must reflect on their specific needs before making a decision. The future of cryogenic dewars will undoubtedly be exciting, but careful consideration is essential.