-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

In the ever-evolving landscape of industrial applications, the demand for high-purity nitrogen has surged significantly, driven largely by its pivotal role in various sectors including pharmaceuticals, electronics, and food processing. As per a report by the Global Nitrogen Market Research, the market for industrial nitrogen has seen a compound annual growth rate (CAGR) of approximately 6% from 2020 to 2025. This increasing demand necessitates efficient and cost-effective methods for nitrogen production, positioning the Cryogenic Nitrogen Generator as an exemplary solution for many industries.

A Cryogenic Nitrogen Generator operates by cooling air to extremely low temperatures, allowing for the separation of nitrogen from other gases. This technology not only ensures a continuous and uninterrupted supply of high-purity nitrogen but also significantly reduces operational costs associated with traditional nitrogen sourcing methods such as cylinder refills and bulk deliveries. According to industry analyses, transitioning to an on-site Cryogenic Nitrogen Generator can lead to savings of up to 25% in overall nitrogen supply expenditures while enhancing production efficiency and control.

Moreover, the adoption of Cryogenic Nitrogen Generators aligns with sustainability goals, as they minimize the carbon footprint associated with transportation and storage of nitrogen gas. As industries strive for greener practices, integrating such innovative technologies has become paramount. Therefore, understanding the benefits and operational dynamics of Cryogenic Nitrogen Generators is essential for companies looking to optimize their nitrogen supply chains and enhance overall operational performance.

Cryogenic nitrogen generators have become increasingly essential in various industrial applications, particularly due to their efficiency and cost-effectiveness. These systems operate by cooling air to extremely low temperatures, allowing nitrogen to be separated and collected. According to a report by the Global Industrial Gases Market, the demand for nitrogen in industries such as food preservation, electronics manufacturing, and metal processing has been rising, with nitrogen usage projected to grow by over 5% annually through 2025. The purity levels of nitrogen supplied by cryogenic generators often exceed 99.999%, making them ideal for sensitive applications where quality cannot be compromised.

In industries like pharmaceuticals and chemical processing, the ability to generate high-purity nitrogen on-site using cryogenic methods can markedly reduce logistics costs and dependency on external gas suppliers. A study by the International Gas Union indicates that the adoption of cryogenic nitrogen generators can lead to operational savings of up to 30%, primarily due to decreased transportation expenses and storage needs. Additionally, implementing such systems enhances overall safety by minimizing the risks associated with handling high-pressure gas cylinders. Thus, understanding the mechanics and benefits of cryogenic nitrogen generators is crucial for industries looking to optimize their processes and meet rising demands efficiently.

Cryogenic nitrogen generators have become a cornerstone for various industrial applications, thanks to their efficiency and reliability. One of the key advantages of using cryogenic nitrogen generators is their ability to produce high-purity nitrogen on-site. According to a report by the Gas Technology Institute, industries utilizing cryogenic techniques can achieve nitrogen purity levels exceeding 99.999%. This purity is critical for sectors like pharmaceuticals and electronics, where even trace impurities can lead to significant product defects.

Moreover, the operational efficiency of cryogenic nitrogen generators significantly improves cost-effectiveness. The global market for industrial gases indicates that facilities transitioning to on-site nitrogen production can reduce costs by up to 30% over traditional methods that rely on bulk deliveries. This reduction is primarily attributed to decreased transportation costs and minimized downtime during operations. Additionally, with components designed for high efficiency in energy consumption, these systems align with sustainability goals, ultimately resulting in lower greenhouse gas emissions.

When comparing cryogenic nitrogen generators to traditional nitrogen production methods, several key differences come to light. Traditional methods, such as pressure swing adsorption (PSA) and cryogenic distillation, often involve complex processes that require extensive infrastructure and ongoing operational costs. For instance, cryogenic distillation, which separates nitrogen from air using significantly low temperatures, often demands substantial energy input and maintenance of large-scale facilities. While these methods provide high purity nitrogen, they also require continuous operation of heavy-duty equipment, leading to increased expenditure over time.

In contrast, cryogenic nitrogen generators are designed to be more efficient and flexible. These systems use the same principles of cryogenic distillation but are contained within a compact setup, making them more accessible for various industrial environments. They can be operated on-demand, producing nitrogen as needed rather than relying on large storage tanks. This immediacy reduces waste and cuts down on excess supply costs associated with traditional methods. Moreover, cryogenic generators often require less manpower and maintenance, allowing companies to allocate resources more efficiently. As a result, industries looking for sustainable and cost-effective nitrogen solutions are increasingly leaning towards cryogenic technology for their operational needs.

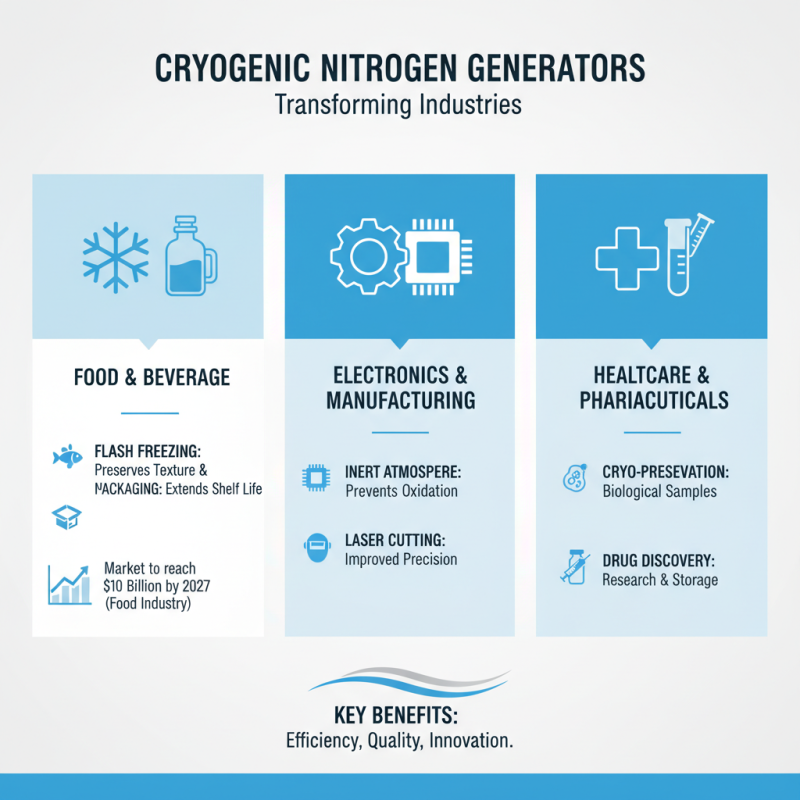

Cryogenic nitrogen generators play a pivotal role in various industries, leveraging the unique properties of nitrogen at extremely low temperatures. One of the primary applications is in the food and beverage sector, where nitrogen is used for flash freezing and packaging. According to a report by MarketsandMarkets, the global market for cryogenic equipment in the food industry is projected to reach USD 10 billion by 2027. The ability to rapidly freeze food products helps in preserving their texture and nutritional value, making cryogenic nitrogen an essential component in modern food processing.

In the manufacturing and metallurgy sectors, cryogenic nitrogen is utilized for material handling and as a protective atmosphere during welding and fabrication processes. Research indicates that the use of cryogenic treatments can enhance the wear resistance of tools and components by up to 50%, significantly extending their lifecycle. Furthermore, in the pharmaceutical industry, cryogenic nitrogen systems are employed for storing sensitive biological samples and conducting various reactions at low temperatures, leading to improved product stability and efficacy. As the demand for high-quality production methods grows, industries are increasingly recognizing the benefits of integrating cryogenic nitrogen systems into their operational frameworks.

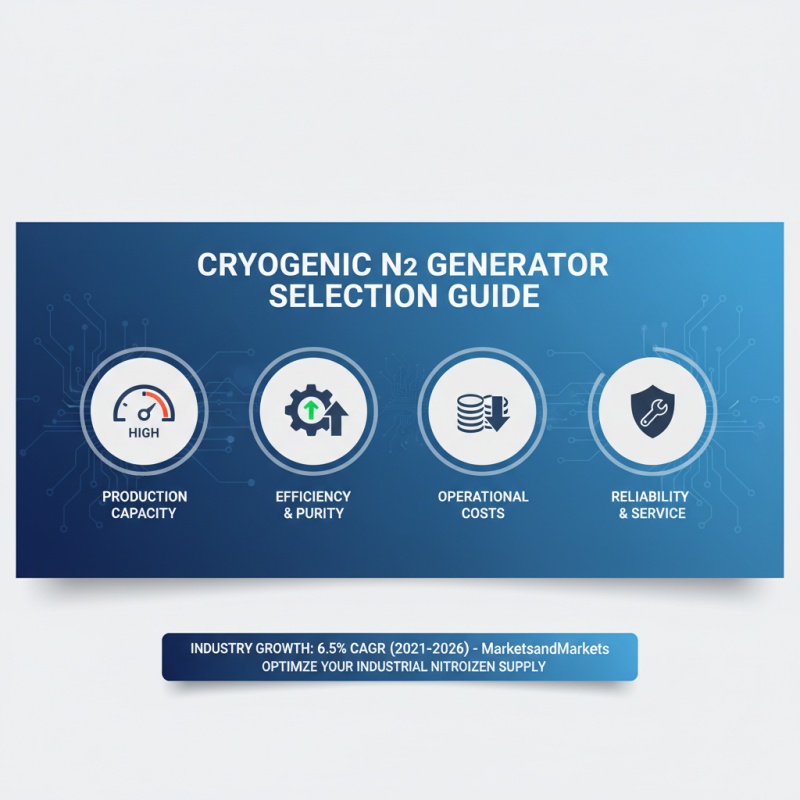

When selecting a cryogenic nitrogen generator for industrial applications, several critical factors must be considered to ensure optimal performance and efficiency. First and foremost, it's essential to evaluate the production capacity of the generator. Depending on your operational requirements, generators can vary significantly in output. According to a recent industry report by MarketsandMarkets, the cryogenic nitrogen generator market is expected to grow at a CAGR of 6.5% from 2021 to 2026, highlighting the increasing demand for high-efficiency nitrogen production solutions tailored to specific industrial needs.

Another important factor to consider is the purity level of the nitrogen produced. Industrial applications often require different purity levels, which can range from 95% to 99.999%. A nitrogen generator's design and technology play a crucial role in achieving these purity levels. The choice between a multi-stage process and a single-stage system can impact not only purity but also energy consumption. According to a study published in the Journal of Industrial Gas, optimizing the recovery and purification processes can lead to a 20% reduction in energy costs, making efficiency a top priority.

Tips: When evaluating potential cryogenic nitrogen generators, always request performance data specific to your needs and compare them across different models. It is also beneficial to consult with industry professionals for recommendations on system design that can maximize efficiency while minimizing operational costs. Another key consideration is the generator's maintenance requirements; choosing a system with lower maintenance needs can significantly reduce downtime and operational expenses.