-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

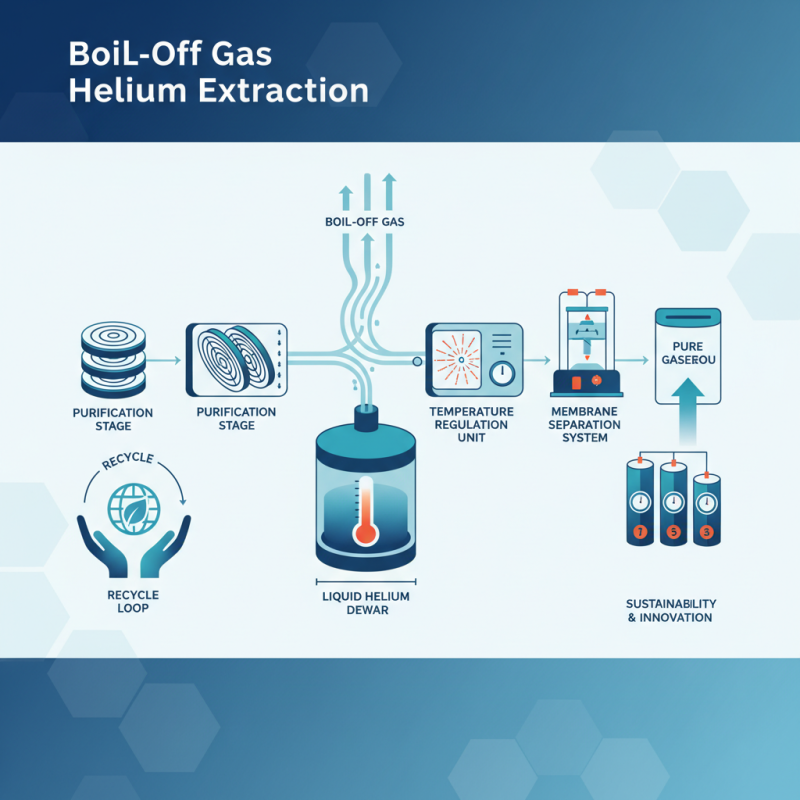

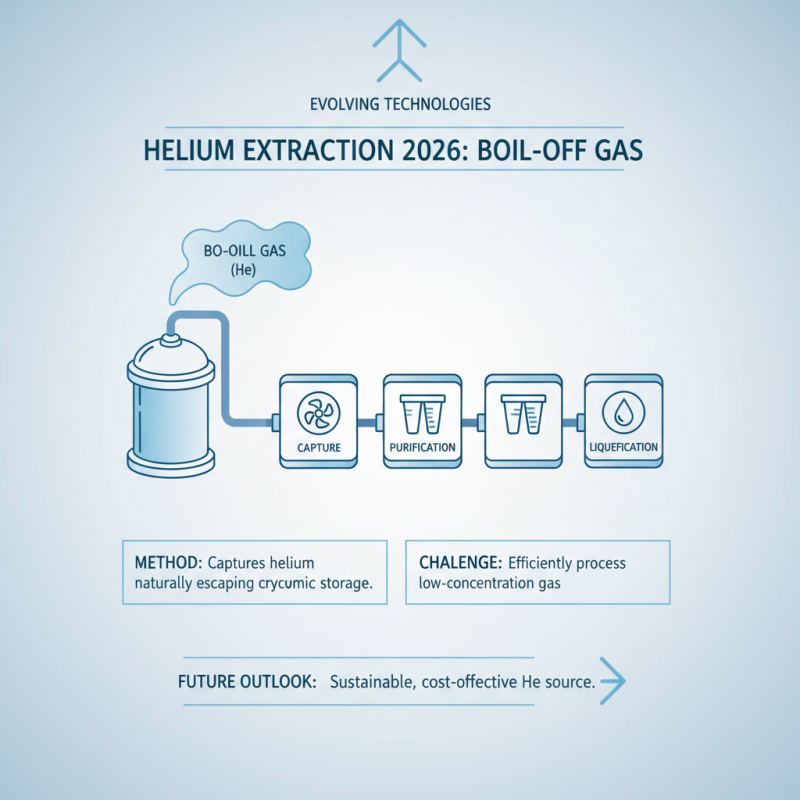

In the rapidly evolving field of helium extraction, "Boil-Off Gas Helium Extraction" stands out as a critical area of focus. According to Dr. Emily Sanchez, a leading expert in gas separation technologies, "Efficient extraction methods will determine the future of helium availability." This quote highlights the urgency of exploring innovative approaches.

In 2026, the industry faces pressing challenges. As helium resources deplete, the need for effective extraction is paramount. Current methods often fall short, leading to unnecessary waste. These inefficiencies not only impact supply but also raise concerns about sustainability. Experts must rethink traditional extraction techniques to improve yield.

Notably, the complexities of "Boil-Off Gas Helium Extraction" cannot be ignored. Factors like temperature fluctuations and equipment reliability play pivotal roles. Each extraction process presents unique hurdles. The industry has room for improvement. Reflections on past techniques can guide future advancements. As we move forward, a collaborative effort is essential. New ideas and innovations will help shape a sustainable helium extraction landscape.

Boil-off gas helium extraction will evolve significantly by 2026. This process involves capturing helium released from high-pressure storage tanks. Efficient extraction methods are essential to reduce waste and enhance recovery. Operators must consider temperature control during this phase. The cooling systems should maintain low temperatures to minimize boil-off.

Training staff on proper techniques is crucial. Knowledge gaps can lead to increased losses. Regular maintenance of valves and seals helps in preventing escape of helium. During extraction, monitoring the flow rate is vital. This ensures that helium recovery remains optimal.

Techniques must adapt to changing environmental conditions. Variations in temperature can impact the efficiency of extraction methods. It’s important to have contingency plans for equipment failures. Continuous improvement in technology and training will play a key role in advancing these practices. Finding the right balance between efficiency and safety is a challenge every team must address.

Helium recovery technologies have advanced in recent years. These methods focus on efficiency and environmental sustainability. One prominent approach is cryogenic distillation. This process condenses gases at extremely low temperatures. It's known for high recovery rates, often exceeding 90%. However, it requires significant energy input, raising concerns about its overall carbon footprint.

Another method is membrane separation. This technique uses selectively permeable membranes to separate helium from other gases. It is more energy-efficient compared to cryogenic methods. However, its effectiveness can vary with gas composition. Sometimes, the purity levels are not as high, leaving room for improvement.

Pressure swing adsorption (PSA) also plays a role in helium recovery. PSA involves cycling between high and low pressures to capture gas. It's a well-established method with flexibility in operation. Despite its strengths, the technology does not always guarantee full recovery. There remains an ongoing need for better technologies that can maximize extraction efficiency while minimizing costs. The quest for the best helium recovery methods continues.

The economic impact of boil-off gas helium recovery is significant in the helium industry. According to the Helium Market Report 2023, the helium market is projected to reach $4.39 billion by 2027. This growth highlights the importance of efficient helium extraction methods. Boil-off gas recovery can reduce waste and generate additional revenue streams.

Implementing effective recovery systems can improve cost efficiency. A study from the International Helium Association found that up to 30% of helium is lost during storage and transport. This inefficiency can potentially cost the industry millions annually. By investing in boil-off gas recovery technologies, companies could recover around 90% of this lost helium, translating to substantial savings.

Despite these benefits, challenges remain. The high initial costs of recovery systems may deter investment. Additionally, fluctuating helium prices create uncertainty in long-term planning. Some companies might hesitate to commit fully to recovery projects. Identifying these issues is crucial for advancing recovery efforts in the industry. Addressing these challenges can enhance profitability while promoting sustainable practices.

| Extraction Method | Energy Consumption (kWh/kg) | Recovery Efficiency (%) | Cost Per Kg ($) | Economic Impact ($M/year) |

|---|---|---|---|---|

| Cryogenic Distillation | 5.0 | 92 | 40 | 200 |

| Membrane Separation | 2.5 | 85 | 55 | 150 |

| Pressure Swing Adsorption | 3.0 | 90 | 50 | 180 |

| Cryogenic Regeneration | 4.0 | 88 | 45 | 220 |

| Hybrid Systems | 3.5 | 91 | 52 | 210 |

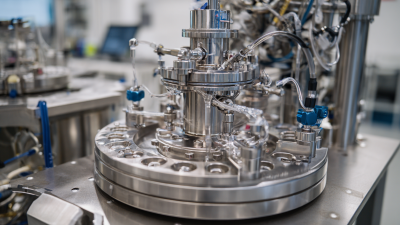

In the quest for efficient boil-off gas helium extraction, methods can be broadly categorized into cryogenic and non-cryogenic techniques. Cryogenic methods operate at extremely low temperatures. They provide high purity levels but can be expensive and energy-intensive. Special equipment often requires regular maintenance.

On the other hand, non-cryogenic methods can be more cost-effective. They use ambient temperatures and are generally easier to implement. However, extraction purity may suffer. A balance between efficiency and cost is key. The choice depends on specific project demands and constraints.

Tips: Consider operating conditions carefully. Even minor adjustments can dramatically affect results. Test various methods on a small scale before full implementation. Keep an eye on maintenance needs; neglect can lead to larger issues down the road. Continue to refine processes to improve efficiency and reduce environmental impact. Always stay updated on advancements in technology; this field evolves quickly.

As we look ahead to 2026, helium extraction technologies are evolving rapidly. One promising area is boil-off gas extraction. This method utilizes helium gas that naturally escapes from storage systems. The challenge lies in efficiently capturing and processing this gas.

Future trends indicate a growing emphasis on automation and smart technology. With better sensors, we can monitor helium levels in real time. Machine learning algorithms will analyze these data points, optimizing extraction processes. However, implementing these advanced technologies is not without obstacles. The cost and complexity of integration can be significant.

**Tip:** Regular maintenance of storage systems is crucial. It helps reduce premature boil-off and maximizes the amount of recoverable helium. Another critical aspect is employee training. Knowledgeable staff can spot inefficiencies that technology alone may miss.

In addition, more research is needed in materials that minimize gas loss during storage. Current solutions aren't perfect. Testing various materials and techniques can lead to significant improvements. As we push the boundaries of what’s possible, we can refine methods to make helium extraction more efficient and sustainable.