-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

In the world of cryogenics, safety is paramount. Cryogenic Liquid Tanks are essential for storing gases like liquid nitrogen and helium. According to industry expert Dr. Emily Carter, “Proper storage is critical for maintaining both safety and efficiency in cryogenic applications.” Her insights remind us that choosing the right tank influences operational success.

The market offers various options, yet not all are created equal. Factors such as design, insulation, and materials can greatly impact performance. A well-designed Cryogenic Liquid Tank minimizes risks like leaks or explosions. However, budget constraints often lead to compromises that can affect safety. Users must consider these elements carefully.

While many tanks seem reliable, issues can arise unexpectedly. Regular maintenance is crucial to identify faults. “An overlooked tank can lead to catastrophic failures,” emphasizes Dr. Carter. Ensuring standards are met is not just about compliance; it’s about safeguarding lives. Moving forward, the industry must prioritize innovation alongside safety.

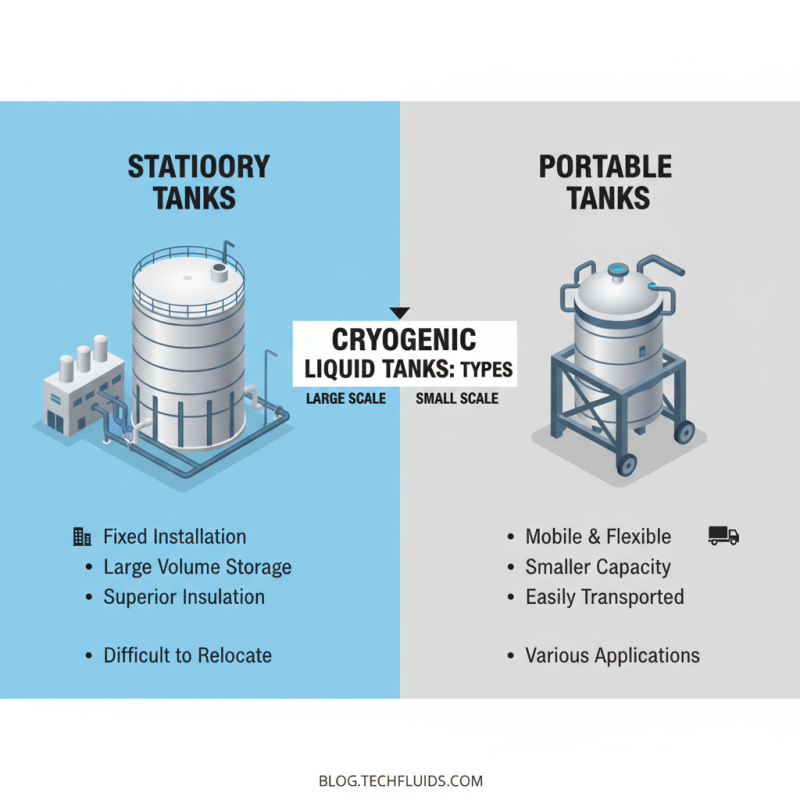

When choosing cryogenic liquid tanks, understanding the types available is crucial. There are two main types: stationary and portable tanks. Stationary tanks are fixed installations. They are ideal for facilities requiring large-volume storage. These tanks tend to have a larger capacity and insulation to maintain extremely low temperatures. However, they are not easy to relocate.

On the other hand, portable tanks offer flexibility. They are often used in applications where mobility is essential. These tanks are generally smaller and easier to transport. However, their capacity may be limited, which can be a drawback for some operations. Additionally, both types require regular inspections. This ensures that they meet safety standards.

Selecting the right tank involves considering specific needs. For example, users must evaluate the types of liquids stored and usage frequency. At times, organizations overlook maintenance protocols. Ensuring compliance with safety measures is vital. This creates a safer working environment, reducing risks associated with cryogenic storage.

When selecting cryogenic liquid tanks, safety and efficiency are paramount. Key features play a crucial role in ensuring optimal storage solutions. The tank's insulation is vital. Vacuum insulation can enhance performance by preventing heat transfer, thus minimizing evaporation losses. According to industry reports, well-insulated tanks can reduce boil-off rates by over 90%, significantly conserving resources.

Material selection is another critical aspect. Stainless steel or aluminum are often preferred for their durability and resistance to extreme temperatures. These materials provide reliable performance under different conditions, ensuring the longevity of the tank. Some tanks also feature reinforced structures, which improve safety during transportation and handling.

**Tips:** Always verify the pressure rating of the tank. This ensures it can withstand the specific requirements of cryogenic liquids. Keeping the tank clean and regularly inspecting it for wear can enhance its lifespan significantly.

Another point to consider is the ease of maintenance. Selecting tanks with accessible valves and gauges simplifies routine checks. Improper maintenance can lead to unforeseen failures, risking both resources and safety.

The storage of cryogenic liquids demands strict adherence to safety standards and regulations. These substances can reach temperatures below -150°C, leading to potential hazards. The American Society of Mechanical Engineers (ASME) sets crucial guidelines for tank design. Certified tanks must endure rigorous testing to prevent leaks and ensure structural integrity.

Regular inspections are essential. The National Fire Protection Association (NFPA) emphasizes that storage tanks should undergo checks at least once a year. Reports indicate that about 5% of incidents involving cryogenic storage stem from inadequate maintenance. These statistics highlight the need for strict adherence to protocols. Operators must recognize that even minor oversights can have severe consequences.

Employee training is vital for safe operations. The Occupational Safety and Health Administration (OSHA) recommends comprehensive training programs for workers handling cryogenic liquids. Lack of knowledge can lead to dangerous situations. Recent surveys show that nearly 30% of workers feel unprepared to manage emergencies. Fostering a culture of safety can mitigate risks effectively. Continuous education can bridge this gap and enhance overall safety in cryogenic environments.

| Tank Type | Capacity (liters) | Material | Insulation Type | Safety Features | Applicable Standards |

|---|---|---|---|---|---|

| Vertical Tank | 5,000 | Stainless Steel | Vacuum Insulated | Pressure Relief Valve, Level Sensors | ASME, DOT |

| Horizontal Tank | 10,000 | Aluminum | Polyurethane | Overpressure Protection, Emergency Shut-off | ISO 9001, EU Regulations |

| Micro Tank | 1,000 | Carbon Steel | Vacuum Insulated | Automatic Venting, Thermal Monitoring | API, NFPA |

| Cryogenic Container | 400 | Stainless Steel | Expanded Foam | Lockable Valve, Safety Gaskets | ISO, CE |

Maintaining the integrity of cryogenic tanks is essential for safety and efficiency. Regular inspections are crucial. Check for signs of corrosion, leaks, and pressure irregularities. The tank's insulation should be intact to prevent temperature fluctuations. Small damages can escalate quickly if ignored. Operators should document each inspection thoroughly to track issues over time.

Tips: Always wear protective gear when working around cryogenic liquids. Ensure proper ventilation in storage areas. Regularly train staff on safe handling procedures.

Cleaning is another vital aspect. Contaminants can affect the quality of cryogenic liquids. Utilize appropriate cleaning agents that do not react with the materials of the tank. Remember that even minor scratches on the tank surface can be a point of concern. A well-maintained tank extends its lifespan and ensures safety.

Tips: Schedule cleaning routines regularly. Use the right tools to avoid damage. Assess cleaning methods to find what works best in your facility.

This bar chart illustrates the storage capacities of various cryogenic liquid tanks. Proper maintenance practices are essential for ensuring the integrity and safety of these tanks during operation.

Cryogenic tank technology is evolving rapidly. Innovations focus on enhancing safety and efficiency. Modern designs incorporate advanced insulation materials. These materials significantly reduce heat transfer. Optimized shapes and sizes help minimize the risk of pressure buildup. Engineers are constantly testing new designs to improve reliability.

Enhanced safety features now include pressure monitoring systems. These systems provide real-time data and alerts. Automatic emergency shut-off valves are becoming standard. They can prevent accidents before they happen. Some tanks even have built-in alarm systems. These features contribute to safer storage practices in various industries.

Despite these advancements, challenges remain. Material fatigue over time can pose risks. Regular maintenance checks are crucial to ensure integrity. Training personnel on proper handling is often overlooked. Attention to detail in safety protocols is essential. Innovations help, but human factors cannot be ignored. Continuous improvement is necessary for achieving ultimate safety in cryogenic storage.