-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

In the realm of cryogenic storage, the Big Capacity Liquid Dewar stands out as a vital innovation. Experts emphasize its importance for high volume applications. Dr. Sarah Weston, a renowned cryogenics specialist, notes, "The efficiency of Big Capacity Liquid Dewars can dramatically enhance operational workflows."

This equipment is designed for optimal performance. It provides incredible insulation to keep liquids at freezing temperatures. Remarkably, it maximizes storage efficiency. Yet, with advancements, challenges still exist. Users often struggle with maintenance and logistics. Proper handling can be a daunting task.

The market is evolving, driving manufacturers to improve designs continuously. A wide variety of options are now available. Choosing the right Big Capacity Liquid Dewar can be overwhelming. Potential buyers must assess their specific needs carefully. Factors like size, insulation material, and usability play key roles. Each decision matters and can affect the overall effectiveness in high volume storage scenarios.

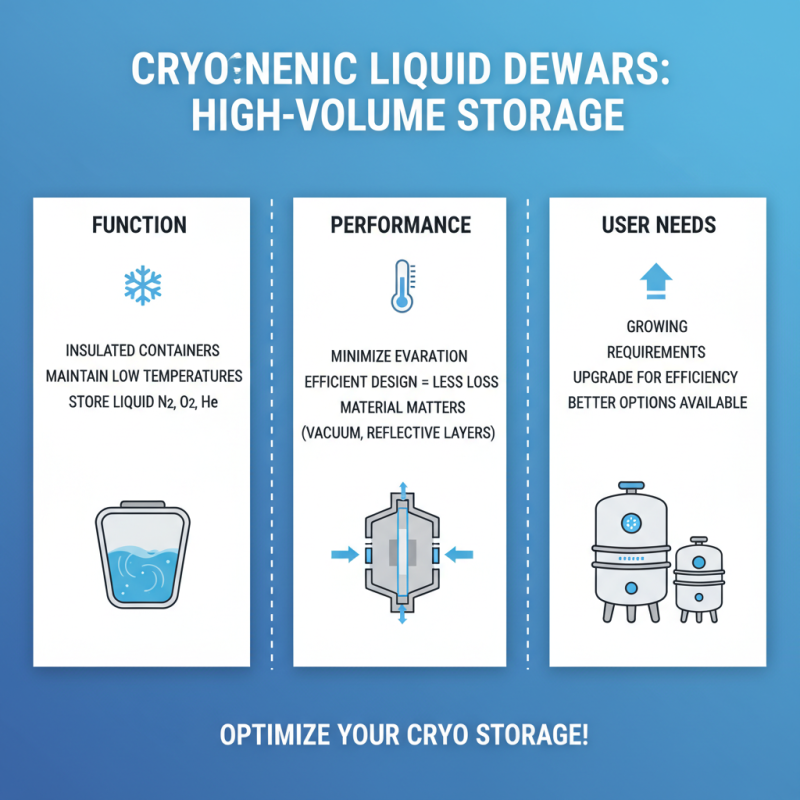

Liquid dewars are vital for high-volume storage of cryogenic liquids. These insulated containers keep substances like liquid nitrogen at low temperatures. Their efficiency depends on design and materials used. A well-designed dewar can prevent significant evaporation. However, not all dewars perform equally. Users often find themselves needing better options as requirements grow.

In industries like healthcare and research, the need for reliable large-capacity dewars is increasing. Liquid dewars must remain stable during transport and storage. Size and weight can be a challenge, making handling difficult. Sometimes, users underestimate the thermal performance. The choice of capacity influences the cooling rate and duration.

Selecting a suitable dewar requires careful consideration. Users should assess their specific storage needs thoroughly. There may be limitations in the available space or budget. Understanding these constraints can help in making a more informed decision. Balancing capacity with practicality can lead to better outcomes in high-volume storage.

When selecting a big capacity liquid Dewar, several key features are important. Insulation quality is critical. Look for Dewars with high thermal efficiency. This will ensure that stored liquids maintain their low temperatures for longer periods. The material construction also matters. Robust materials enhance durability, preventing leaks and accidental damage.

Tips: Always check the weight of the Dewar. A heavier Dewar often indicates high-quality insulation. Balance is essential; a Dewar that’s too heavy may be impractical for regular use.

Capacity plays a crucial role. Ensure the Dewar meets your storage needs without wasting space. Consider dimensions. A bulky Dewar can be challenging to move. However, if it’s too compact, you might find yourself refilling it often.

Tips: Assess the Dewar’s neck size. A wider neck can simplify filling and transfer but may increase heat transfer rates. Balancing size and efficiency is key. Remember, a liquid Dewar can also be a significant investment. Consider your long-term usage before making a choice.

| Model | Capacity (liters) | Insulation Type | Weight (kg) | Temperature Range (°C) | Warranty (years) |

|---|---|---|---|---|---|

| Model A | 50 | Vacuum Insulation | 25 | -196 to 50 | 5 |

| Model B | 100 | Multi-Layer Insulation | 30 | -196 to 70 | 3 |

| Model C | 200 | Foam Insulation | 40 | -196 to 60 | 2 |

| Model D | 300 | Vacuum Insulation | 50 | -196 to 80 | 4 |

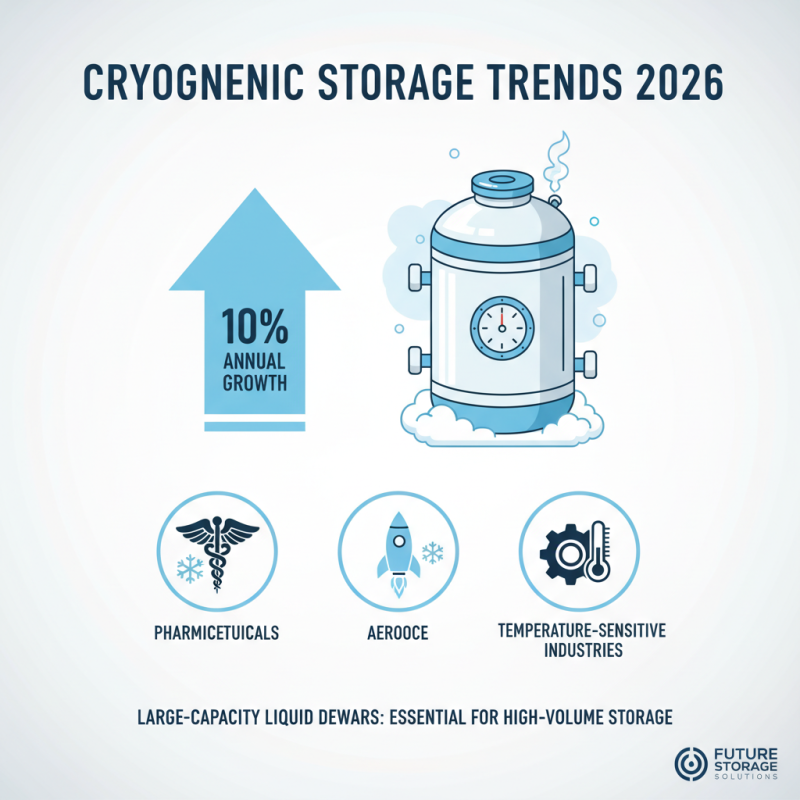

When considering high-volume storage solutions in 2026, big capacity liquid dewars are crucial for various industries. They are essential in sectors like pharmaceuticals and aerospace, where maintaining specific temperatures is vital. According to a recent industry report, the demand for large capacity dewars is expected to grow by over 10% annually, reflecting the rising need for efficient cryogenic storage.

Many facilities seek dewars that can hold up to 200 liters or more. However, choosing the right one often involves careful consideration. Some units, while spacious, may lack effective insulation, resulting in increased evaporation rates. A report from Cryogenics Today indicated that inefficient dewars could lead to a 15% loss in liquid volume, which translates into significant cost implications.

Another aspect to reflect on is portability. Some dewars are cumbersome, making transport a challenge. High-capacity models must balance volume and weight, ensuring they remain manageable for staff. Additionally, safety features vary widely between products. This inconsistency can pose risks, highlighting the need for thorough evaluations before making a purchase.

When it comes to liquid dewars, material choice significantly affects storage efficiency. Common materials include stainless steel and aluminum. Stainless steel offers durability but is heavier. Aluminum, on the other hand, is lighter but can be less protective in harsh environments. According to industry reports, approximately 70% of heavy-duty liquid dewars are made of stainless steel. This material excels in high-volume settings but may lead to increased shipping costs due to weight constraints.

Insulation is another critical aspect. Dewars typically use vacuum insulation or foam insulation. Vacuum insulation minimizes heat transfer. However, vacuum-sealed designs can be susceptible to damage. Foam insulation offers less efficiency than a vacuum but provides resilience, making it suitable for transport scenarios. Research indicates that dewars with vacuum insulation can retain liquid nitrogen temperatures for up to 10 days. This is ideal for users needing long-term storage but not always realistic for frequent use.

Even though technological advancements improve efficiency, challenges remain. For example, ensuring long-term integrity of the materials is an ongoing concern. Bonding processes used in manufacturing can lead to potential weak spots. Users must weigh the pros and cons carefully. Performance can vary significantly, based on the specific needs and environments in which dewars are utilized. The balance between durability and efficiency is not easily achieved and requires constant evaluation to meet varying demands.

Maintaining big capacity liquid dewars is crucial for optimal performance. Regular checks are essential to ensure safe operation. According to recent industry reports, a properly maintained dewar can last over ten years. However, neglect can lead to significant losses, as improper storage may vaporize valuable contents.

Monitoring levels and temperatures is vital. Dewars should be filled to recommended levels to prevent damage. Also, regular vacuum insulation checks are necessary. Insulation failure can cause energy loss, affecting storage quality. Studies show that maintaining optimal storage temperatures increases lifespan by 20-30%.

Cleaning the exterior and probes regularly is often overlooked. Dust and residues can lead to corrosion. It’s a simple task but essential for long-term use. Using appropriate cleaning agents is crucial; harsh chemicals can cause more harm than good. Training personnel on best practices is another key point. Even minor mistakes can lead to expensive mishaps. Simple awareness can make a drastic difference in durability and functionality.