-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

The Cryogenic Refrigeration System plays a crucial role in various industries. Its benefits extend beyond mere temperature control. These systems use extremely low temperatures to preserve, store, and transport materials. They are vital in sectors like medicine, food processing, and aerospace.

In the medical field, cryogenic refrigeration ensures the longevity of vaccines and organs. This preservation method is critical during transportation and storage. In food processing, it enhances product quality and shelf life. The system significantly reduces spoilage and waste.

Despite their advantages, cryogenic systems demand careful operation. The costs can be high, and they require specialized maintenance. Additionally, the technology is complex and may pose safety concerns. These challenges highlight the need for ongoing research and refinement in the field. The journey of understanding the full potential of the Cryogenic Refrigeration System is ongoing.

Cryogenic refrigeration systems play a vital role in numerous industrial applications. These systems achieve extremely low temperatures, typically below -150 degrees Celsius. This allows them to preserve materials that require extreme conditions, such as certain medical supplies. According to the Cryogenic Society of America, these systems can reduce energy consumption by up to 30% compared to standard refrigeration methods.

These systems utilize liquid gases like nitrogen and helium. The process relies on Joule-Thomson expansion to cool. One area of concern is the efficiency of these systems. Research from the American Society of Heating, Refrigerating and Air-Conditioning Engineers shows that improper maintenance can lead to a 20% decrease in system efficacy. Addressing such inefficiencies is crucial for operation.

Moreover, safety considerations are essential. Cryogenic materials can pose hazards if not managed properly. An industry report noted that over 10% of incidents relate to improper system handling. While these systems are beneficial, they require careful training and protocols. It’s clear that while cryogenic refrigeration systems provide remarkable advantages, they also demand ongoing scrutiny and improvement.

| Benefit | Description |

|---|---|

| Energy Efficiency | Cryogenic systems often use less energy compared to traditional refrigeration methods. |

| Lower Operating Costs | Reduced energy consumption leads to lower operational costs over time. |

| Enhanced Product Quality | Cryogenic temperatures preserve the quality of products better by minimizing thermal damage. |

| Versatility | Cryogenic systems can be adapted for a variety of applications, from food storage to medical uses. |

| Environmentally Friendly | These systems can use less harmful refrigerants, reducing environmental impact. |

| Increased Storage Capacity | Advanced cryogenic solutions allow for more efficient space utilization within storage facilities. |

| Safety | With proper design, cryogenic systems can be operated safely with fewer risks of leaks. |

| Fast Cooling | Cryogenic systems can cool products rapidly, which is beneficial for preserving sensitive materials. |

| Longer Shelf Life | The low temperatures extend the shelf life of products significantly. |

| Improved Performance | Cryogenic refrigeration enhances the performance of various industrial processes. |

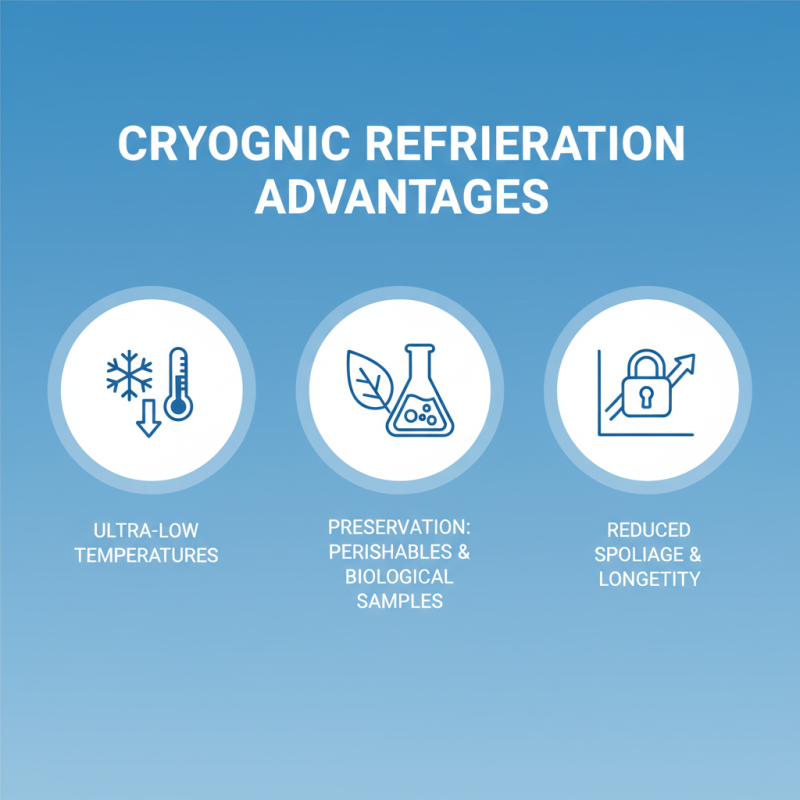

Cryogenic refrigeration systems offer several key advantages in various industries. One of the primary benefits is their ability to achieve extremely low temperatures. This makes them ideal for preserving perishable goods and sensitive biological samples, such as cells and tissues. Maintaining optimal storage conditions can significantly reduce spoilage and ensure the longevity of valuable assets.

Another significant advantage lies in their efficiency. These systems generally consume less energy than traditional refrigeration methods. This energy-saving aspect can drastically reduce operational costs over time. Additionally, they produce minimal emissions, thereby contributing to a greener environment. However, the complexity of these systems can pose challenges. Regular maintenance is essential to avoid performance issues.

Moreover, cryogenic systems are highly versatile. They can be adapted for various applications, from food preservation to pharmaceuticals. Their capacity for quick cooling makes them crucial in medical and scientific research. Yet, spaces equipped with cryogenic systems must be carefully monitored. Proper training for personnel is necessary to ensure safety and effective use. Balancing these advantages with potential hurdles is vital for successful integration.

Cryogenic refrigeration systems play a crucial role in various industries. They provide extremely low temperatures, essential for certain manufacturing processes. In the medical field, they are invaluable for preserving biological samples and medicinal substances. This preservation extends the life and efficacy of vital materials.

In food processing, cryogenic refrigeration is used to freeze large quantities of food quickly. This method helps retain flavor and texture. It is an energy-efficient solution, yet it can be complex and costly to implement. Industries must weigh the benefits against potential challenges. The semiconductor industry also relies heavily on cryogenic techniques for cooling during fabrication. High precision is necessary, but operational costs can sometimes be a hurdle for smaller enterprises.

A downside remains. Not all companies can afford such advanced technology. Maintenance can be tricky, with equipment needing regular checks. Despite these challenges, the advantages often outweigh the drawbacks. Cryogenic refrigeration continues to shape how industries operate today.

Cryogenic refrigeration systems have a distinct impact on the environment and energy consumption. These systems operate at extremely low temperatures, allowing them to minimize energy losses. They use advanced technologies to achieve better performance compared to traditional systems. This efficiency can lead to significant reductions in energy bills.

However, there are challenges. The production and maintenance of cryogenic systems still involve considerable energy use. For example, the liquefaction of gases can be energy-intensive. Moreover, the materials used may not always be environmentally friendly. Improper disposal of these materials could lead to contamination.

The balance between benefits and drawbacks is delicate. Cryogenic systems can reduce emissions but require initial energy investment. Industry leaders must consider life-cycle impacts. Sustainable practices in production and operation can enhance their overall benefits. Effective recycling and proper management of materials are essential for minimizing environmental harm. These factors are crucial for fostering energy efficiency in the long run.

This bar chart illustrates the energy efficiency and environmental impact of cryogenic refrigeration systems compared to traditional refrigeration systems. The data highlights the potential greenhouse gas emissions reduction, energy savings, and enhanced performance that cryogenic systems offer.

Future trends in cryogenic refrigeration technologies are quite exciting. As industries prioritize energy efficiency, cryogenic systems are evolving. Innovations in materials and designs are enhancing performance. For instance, advanced superconducting materials are being tested for better efficiency. This could reduce energy consumption in cooling processes.

Another notable trend is the integration of AI and IoT. These technologies enable smarter monitoring and control of cryogenic systems. They help in real-time data analysis, ensuring optimal performance. However, the implementation can be tricky. Not all facilities have the infrastructure to support these advancements.

Sustainability is also becoming crucial. Researchers are focusing on reducing the environmental impact of cryogenic systems. New refrigerants with lower global warming potential are being developed. Yet, many existing systems still rely on older refrigerants. The transition is not as seamless as one might hope. This presents challenges that need careful consideration moving forward.