-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

Compressed gas plays a pivotal role in various industries, providing a versatile solution for a wide array of applications. According to the Compressed Gas Association, the global market for compressed gases is expected to reach approximately $75 billion by 2027, reflecting a substantial growth driven by demand in sectors such as healthcare, manufacturing, and energy. In the healthcare industry, for instance, compressed gases are essential for anesthetic procedures and respiratory therapies, highlighting their importance in patient care. Moreover, the manufacturing sector utilizes compressed gas for powering machinery, assisting in welding processes, and even in the production of food and beverages, underscoring its multifunctionality.

In addition to its widespread applications, compressed gas offers significant advantages that contribute to operational efficiency and safety. For example, the use of compressed air in pneumatic tools not only enhances productivity but also reduces the risk of electric-related accidents. Furthermore, the energy efficiency associated with compressed gas technologies can lead to cost savings, as noted in a recent report by the U.S. Department of Energy, which found that optimized use of compressed air systems can reduce energy consumption by up to 30%. As industries continue to evolve, the role of compressed gas remains critical, driving innovation and efficiency across various sectors.

Compressed gas plays a critical role across various industries, serving as an essential component in processes ranging from manufacturing to healthcare. According to the Compressed Gas Association, the applications of compressed gas are extensive; approximately 80% of industrial processes utilize some form of compressed gas, including air, nitrogen, and oxygen. In the manufacturing sector, for instance, compressed air is commonly employed for powering pneumatic tools, which enhances productivity and efficiency. Moreover, in chemical manufacturing, gases like hydrogen and argon are vital for various reactions and processes, which helps optimize production quality.

In healthcare, compressed gas is integral to patient care. Medical-grade gases such as oxygen and nitrous oxide are utilized in hospitals for patient management and anesthesia, respectively. The World Health Organization reports that approximately 70% of patients undergoing surgery rely on oxygen delivery systems, emphasizing the critical nature of these gases in clinical settings. Additionally, industries like food and beverage utilize compressed gases for carbonation, preservation, and packaging, with the global food gas market projected to reach USD 6.25 billion by 2025. This demonstrates the diverse applications of compressed gas in boosting operational efficiency, enhancing product quality, and ensuring safety across multiple sectors.

Compressed gas technologies play a crucial role in various industries, offering a range of applications that enhance efficiency and sustainability. In the manufacturing sector, compressed gas is essential for powering pneumatic tools and machinery, streamlining operations, and improving process control. Industries such as automotive rely heavily on compressed air for tasks like painting, tire inflation, and assembly, enabling precision and speed in production lines.

The food and beverage industry also benefits significantly from compressed gas technologies. Carbon dioxide, for instance, is used for carbonation in soft drinks and as a preservative to extend shelf life. Nitrogen is utilized in packaging to create an inert atmosphere, reducing spoilage and maintaining product quality.

Additionally, the pharmaceutical sector employs compressed gases in various applications, including the delivery of medications and the sterilization of equipment, ensuring safety and efficacy in treatments. As industries continue to innovate, the versatility of compressed gases remains a vital asset across multiple sectors.

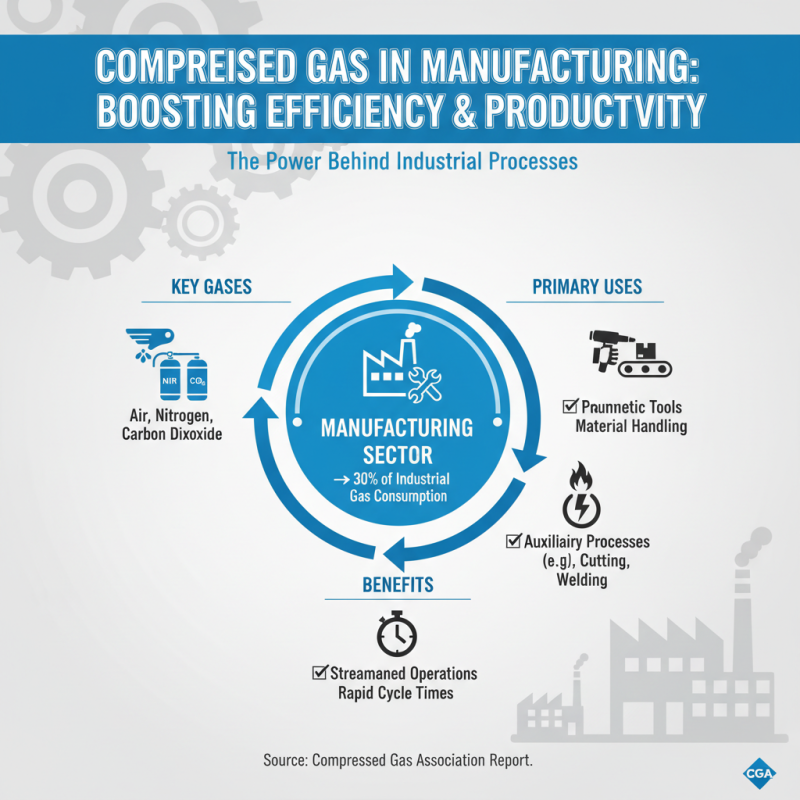

Compressed gas plays a crucial role in various manufacturing processes, providing numerous benefits that enhance efficiency and productivity. According to a report by the Compressed Gas Association, the manufacturing sector accounts for approximately 30% of the total consumption of industrial gases, underscoring their significance in this domain. Compressed gases, such as air, nitrogen, and carbon dioxide, are used extensively for pneumatic tools, material handling, and as auxiliary processes in manufacturing. This utilization not only streamlines operations but also reduces downtime by enabling rapid cycle times.

One of the key advantages of using compressed gas in manufacturing is its ability to improve precision and control in processes like welding, painting, and surface coating. Industry data indicates that manufacturers implementing compressed air systems can achieve energy savings of up to 30% through the optimization of their pneumatic tools. Additionally, the compatibility of compressed gases with various materials ensures that they can be used without altering the integrity of the workpieces. As industries seek to enhance both sustainability and productivity, the role of compressed gas continues to grow, highlighting its essential function in modern manufacturing strategies.

Compressed gas plays a pivotal role across various industries, ranging from manufacturing to healthcare. However, the use of these gases comes with a host of safety considerations and regulatory requirements that must be strictly followed. According to the National Fire Protection Association (NFPA), improper handling or storage of compressed gases can result in serious incidents, including explosions and toxic exposures. Organizations must conduct regular risk assessments and implement comprehensive training protocols to ensure that employees are familiar with the safety measures pertaining to the specific gases they work with.

One critical safety consideration is proper storage and labeling of compressed gas cylinders. The Occupational Safety and Health Administration (OSHA) stipulates that cylinders should be secured in an upright position and stored away from heat sources and flammable materials. It's essential to label cylinders clearly to avoid mix-ups that could lead to dangerous situations.

Tips: Always check valves for leaks before using a gas cylinder, and ensure that the working area is well-ventilated. Additionally, putting up clear signage around areas where compressed gases are used can help reinforce safety protocols and remind personnel of the hazards involved. Routine maintenance and keeping up-to-date with regulatory changes are vital to fostering a safe working environment.

The utilization of compressed gas is driving significant changes across various industries, with future trends suggesting a shift towards more sustainable and efficient applications. According to a report by the International Energy Agency, the demand for compressed natural gas (CNG) is expected to grow at a compound annual growth rate (CAGR) of 5% over the next decade, primarily fueled by its adoption in transportation and industrial sectors. Companies are increasingly investing in CNG as a cleaner alternative to traditional fuels, aiming to reduce greenhouse gas emissions and comply with stricter environmental regulations.

In the manufacturing sector, the trend towards automation and increased productivity has led to a higher reliance on compressed air systems. The Compressed Air and Gas Institute indicates that approximately 70% of all industrial facilities use compressed air in some capacity, with the market projected to reach $40 billion by 2027. Innovations in energy-efficient compressors and smart technologies are expected to enhance the operational efficiency of these systems, leading to significant cost savings and reduced energy consumption. Furthermore, the adaptability of compressed gas in sectors such as healthcare, pharmaceuticals, and food processing highlights its versatile applications, paving the way for continued advancements and integration into diverse industrial processes.