-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

The transportation of chemical liquids is a critical aspect of industry safety. According to the American Chemistry Council, over 90 percent of chemical products are transported via truck, rail, or waterway. Each mode presents unique hazards. Effective practices in chemical liquid transportation are essential in reducing incidents. However, the industry still faces challenges. While regulations exist, not all companies adhere to best practices.

Recent studies indicate that about 1,200 incidents occur annually during transportation. Poor packaging is a significant contributor to these incidents. Inadequate training of staff leads to mistakes that could have devastating effects. Moreover, emergency response teams often lack proper resources for chemical liquid spills. These details highlight the need for improvement in safety protocols.

Fostering a culture of safety is vital. Continuous training and transparent communication can mitigate risk. Organizations must invest in better equipment and adhere to industry standards. The journey to safety in chemical liquid transportation is ongoing. Recognizing flaws in current practices is the first step towards change.

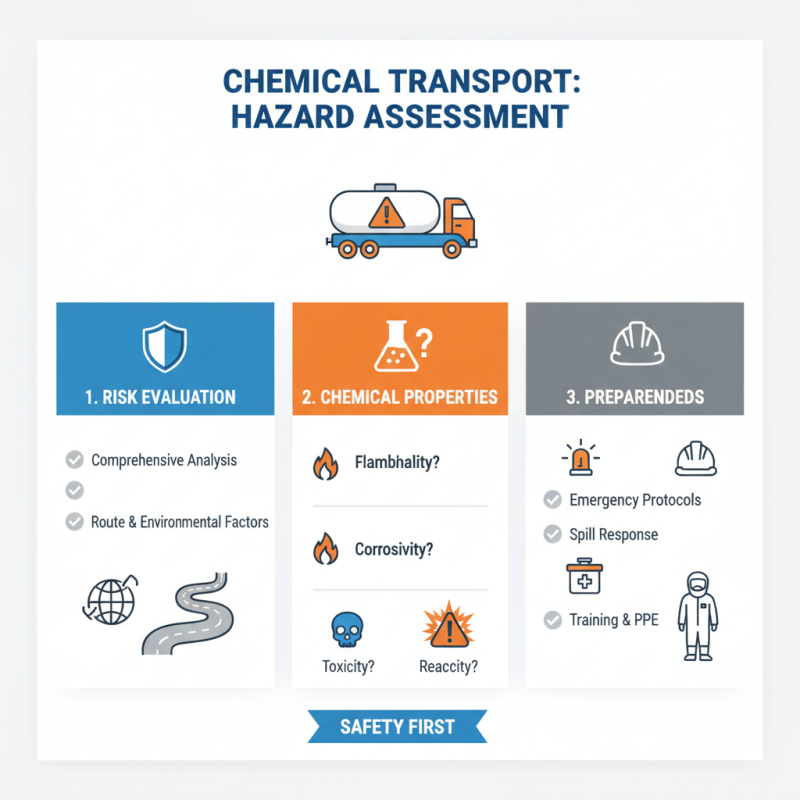

Assessing hazards in chemical liquid transportation is vital. Companies must start with a comprehensive risk evaluation. Identify chemical properties first. Are they flammable or corrosive? Understanding these characteristics helps in preparing for potential incidents.

Next, consider the transport conditions. Weather can change quickly. Rain or snow may impact visibility and road conditions. Vehicles need proper maintenance to ensure they can handle these challenges. Not all transport vehicles are perfect. Some may have outdated safety features, which requires reflection and action.

Finally, training is essential. Workers should understand the risks associated with chemicals. Regular drills can test their readiness. It’s easy to overlook training amid busy schedules. This can lead to gaps in knowledge. Adopting a proactive approach to safety can help prevent accidents. Every detail matters. Taking time to assess these risks can save lives.

When transporting chemical liquids, effective packaging is crucial. Containers and materials must withstand various conditions. Leaking can cause severe environmental damage. It's vital to choose the right type of packaging for each specific chemical. Each chemical has unique properties that require specific handling and packaging solutions.

Using durable materials, such as plastics or metals, can enhance safety. However, not all containers are created equal. Regular inspections are essential to ensure their integrity. Labels should be clear and visible to prevent mishandling. Training personnel about the specifics of packaging is often overlooked. Proper education fosters awareness of potential risks.

Even the best packaging can fail. Incidents happen, and not all situations are perfect. Consider a failure point in the packaging process; it might highlight gaps in safety protocols. Every step must be monitored to minimize errors. Striving for better practices involves constant reflection and improvement. We must acknowledge that ongoing evaluation is key to enhancing safety standards in chemical liquid transport.

Training and certification standards for transport personnel in chemical liquid transportation are crucial for safety. The International Association of Chemical Transport (IACT) reports that nearly 5,000 incidents occur annually in this sector. Proper training can significantly reduce this risk.

Personnel must understand the properties of chemicals they handle. Knowledge about hazardous materials is vital. In 2022, over 60% of chemical spills were caused by human error. Training programs should cover emergency response, risk assessment, and safe handling techniques. A mix of hands-on training and classroom instruction ensures effectiveness.

Certification programs should be regularly updated to reflect industry changes. Many professionals lack basic knowledge of safety protocols. Only 45% are familiar with current regulations, according to industry surveys. Companies must prioritize ongoing education. Regular assessments can identify training gaps and foster a culture of safety.

| Training Program | Duration (Hours) | Certification Validity (Years) | Key Topics Covered | Assessment Method |

|---|---|---|---|---|

| Hazardous Materials Handling | 16 | 3 | Personal Protective Equipment, Emergency Response, Risk Assessment | Written Exam and Practical Demonstration |

| Transportation Safety Training | 24 | 2 | Regulatory Compliance, Vehicle Safety Checks, Incident Management | Multiple-choice Test |

| Emergency Preparedness | 12 | 3 | Evacuation Plans, Spill Containment, First Aid | Scenario-based Exercise |

| Chemical Safety Awareness | 8 | 1 | Chemical Properties, Labeling, Resource Management | Group Discussion |

When transporting chemical liquids, emergencies may arise. Spills can occur due to accidents or equipment failure. Having an effective emergency response protocol is crucial. Quick and determined action can reduce the impact of a spill. Transporters must identify potential risks beforehand. Training staff in spill management is vital.

Tips for spill response: Keep emergency kits onboard. Include absorbent materials and protective gear. Regular drills prepare your team for unexpected situations. Communication is key. Establish clear channels to report incidents to authorities immediately.

Always evaluate your response plan. Did the team act swiftly? Were supplies adequate? Reflection is essential for improvement. Minor tweaks can enhance your protocols. Consider conducting routine reviews. Analyze past incidents to highlight weaknesses. Being prepared is not just a best practice; it can save lives and the environment.

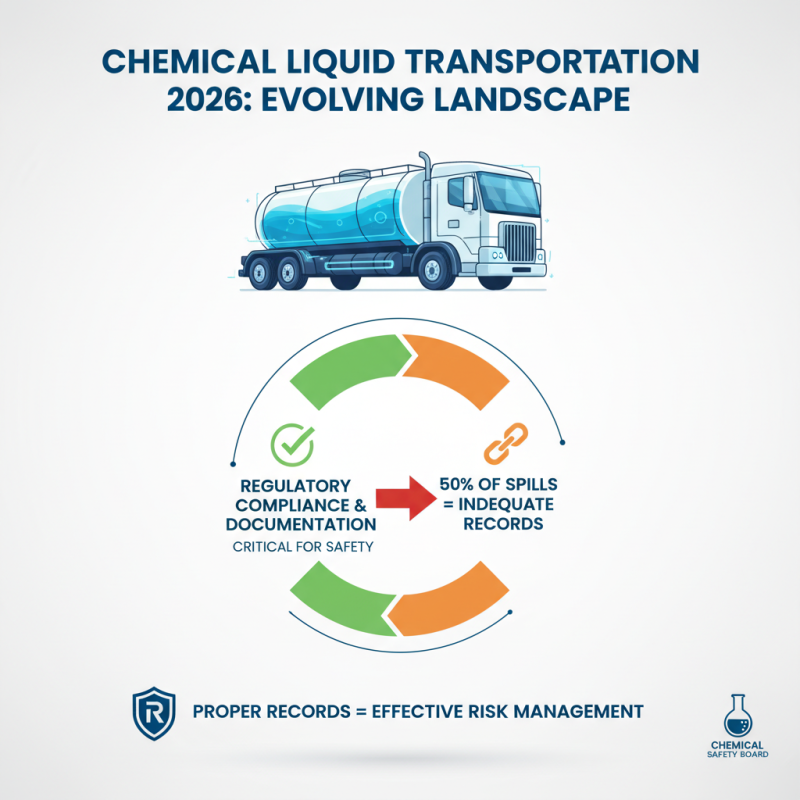

In 2026, the landscape of chemical liquid transportation is evolving. Regulatory compliance and documentation remain critical for safety. According to a recent report by the Chemical Safety Board, nearly 50% of chemical spills are linked to inadequate documentation practices. Proper records help transporters manage risks effectively.

Every shipment requires specific documentation. This includes Safety Data Sheets (SDS) and transport manifests. Gaps in these documents can lead to severe incidents. Statistically, businesses with robust documentation processes report a 30% reduction in accidents. However, many companies overlook routine updates and staff training, leading to compliance breaches.

Reflection is essential in this field. Many professionals assume that once systems are in place, they are sufficient. This mindset can be dangerous. Regular audits and employee feedback are crucial for continuous improvement. The focus must remain on evolving practices to prevent future mishaps in chemical transport.